Small Table Mirror

From DT Online

Design Brief

Design and make a small table mirror based around a 150mm x 150mm square mirror.

Materials Available

- Either a 150mm x 150mm square mirror tile or one cut from 3mm thick Acrylic mirror sheet.

- 3mm and 4mm Acrylic sheet on which the mirror is mounted.

- 5mm dia Pop Rivets and backing washers.

- 15mm - 20mm thick timber or 2mm Aluminium sheet for underframes if required as alternatives to Acrylic.

Considerations

- How can an appropriate viewing angle be assessed?

- Will the mirror need to be adjustable?

- How will stability be ensured?

- Will the mirror need to match a particular room décor?

Ideas

Mirrors are mounted on to plastics sheet using Double-side Tape, Foam Mounting Pads or similar. Underframes may be created by Line Bending Acrylic sheet or by using timber and Corner Joints.

The mirror itself can be enhanced by Sandblasting or Engraving if suitable equipment is available, but a more accessible alternative may be to mask off a design with tape or self-adhesive film and use a low voltage mini-engraver or similar, to create a ‘frosted’ surface where exposed.

Design Development and Construction

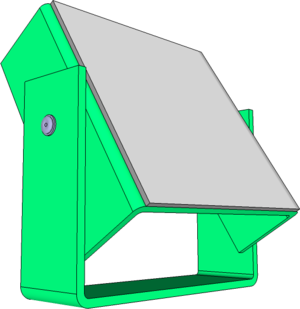

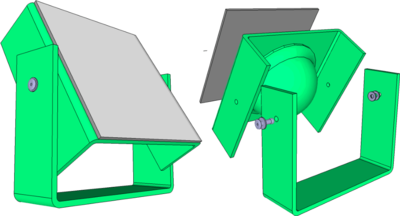

The mirror can mounted on Acrylic sheet which is then formed by Blow Moulding, Line Bending or both.

If Blow Moulding is used, start with this process first, choose a larger Acrylic sheet and shape to size after.

An allowance can be made to position a Pop Rivet pivot point if needed (e.g. by Line Bending as shown).

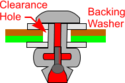

Note: When using Pop Rivets in Brittle materials such as Acrylic, drill over-sized holes and fit backing washers either side to ensure the material is subjected only to Compression and the rivet is prevented from creating Tension as it swells inside the hole.

Testing and Evaluation

- Estimate the materials and production costs of your completed mirror (estimate a cost for your time and add a percentage to allow for equipment and energy use).

- How does the cost of your product compare with similar commercial examples?

- If commercial products are less costly why might this be so?

- Can you think how your design could be made more economically?

- Are there particular features or characteristics of your design which would justify a higher retail price?