Butt Joint: Difference between revisions

From DT Online

(Added reinforcement) |

mNo edit summary |

||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=====Description===== | |||

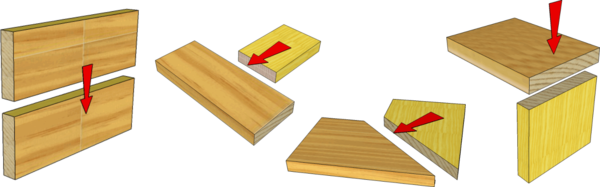

A [https://en.wikipedia.org/wiki/Butt_joint#Screwed_butt_joint '''Butt Joint'''] is a simple coming together of two edges or faces. The joints can be fixed by simply gluing but more often is reinforced or strengthened before doing so. '''Butt Joints''' can be used to widen boards, make frames and create carcasses. | A [https://en.wikipedia.org/wiki/Butt_joint#Screwed_butt_joint '''Butt Joint'''] is a simple coming together of two edges or faces. The joints can be fixed by simply gluing but more often is reinforced or strengthened before doing so. '''Butt Joints''' can be used to widen boards, make frames and create carcasses. | ||

[[File:ButtJoints.png|600px|right]] | [[File:ButtJoints.png|600px|right]] | ||

| Line 5: | Line 5: | ||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

When used to widen boards, '''Butt Joints''' are quite often simply glued and this is known as a ''' | When used to widen boards, '''Butt Joints''' are quite often simply glued and this is known as a '''[[Widening Joint#Rubbed_Joint|Rubbed Joint]]'''. | ||

</span> | </span> | ||

< | |||

__TOC__ | |||

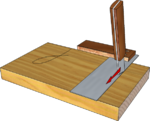

[[File:CornerLapMarkingKnife.png |150px|left]] | |||

It is important to ensure that the ends of timber forming the joint are cut accurately and '''[[Squareness|Square]]'''. This can be achieved ''off the saw'' if care is taken using a '''[[Tenon Saw]]''' and a '''[[Mitre Box]]''' for example. Alternatively a '''[[Precision Mitre Saw]]''' or '''[[Radial Arm Saw]]''' will produce more predictable results. In all cases, scribing the joint lines with a '''[[Marking Knife]]''' will help to ensure clean edges at the joint face. | |||

---- | |||

<span style="color: red">'''Safety Point!''' | |||

Students may only use a '''[[Chop Saw]]''' or '''[[Radial Arm Saw]]''' when they have been trained and assessed and the assessment shows that they are competent, and are under appropriate supervision by specifically trained staff. | |||

</span> | |||

---- | |||

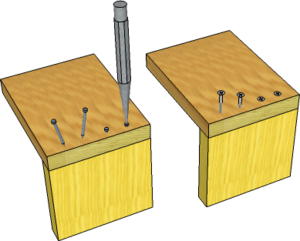

=====Reinforcing Butt Joints===== | =====Reinforcing Butt Joints===== | ||

[[File:ButtJointNailedScrewed.png|300px|left]] | [[File:ButtJointNailedScrewed.png|300px|left]] | ||

| Line 15: | Line 28: | ||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

Nails should be angled or ''''Dovetailed'''' for additional grip and screws should be chosen which are twice the length and a thinner gauge when screwing into '''End Grain''' | Nails should be angled or ''''Dovetailed'''' for additional grip and screws should be chosen which are twice the length and a thinner gauge when screwing into [https://en.wikipedia.org/wiki/Wood_grain '''End Grain''']. | ||

</span> | </span> | ||

<div style="clear: both;"></div> | |||

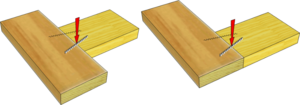

[[File:ButtTeeScrewed.png|300px|right]] | [[File:ButtTeeScrewed.png|300px|right]] | ||

Where it is not possible to screw directly through one part of the joint to the other ''(e.g. need to conceal screw heads or lack of access)'', screws can be sunk into ''' | Where it is not possible to screw directly through one part of the joint to the other ''(e.g. need to conceal screw heads or lack of access)'', screws can be sunk into '''[[Screw Pocket|Pockets]]'''. These are holes drilled at an angle to the work surface to '''[[Counterboring|Counterbore]]''' the screw head as shown. | ||

| Line 26: | Line 40: | ||

[[File:ButtJointCorrugatedFasteners.png|300px|left]] | [[File:ButtJointCorrugatedFasteners.png|300px|left]] | ||

* '''[[Nails and Pins|Corrugated Fasteners]]''' | * '''[[Nails and Pins|Corrugated Fasteners]]''' | ||

These provide a low cost and quick means of joining together a '''Butt Jointed''' frame. They are suitable for coarse joinery work and for assembling frames which are later ''skinned'' with '''Ply''', '''Hardboard''', or '''MDF''' for example. | These provide a low cost and quick means of joining together a '''Butt Jointed''' frame. They are suitable for coarse joinery work and for assembling frames which are later ''skinned'' with '''[[Manufactured Board|Ply]]''', '''[[Manufactured Board|Hardboard]]''', or '''[[Manufactured Board|MDF]]''' for example. | ||

---- | ---- | ||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

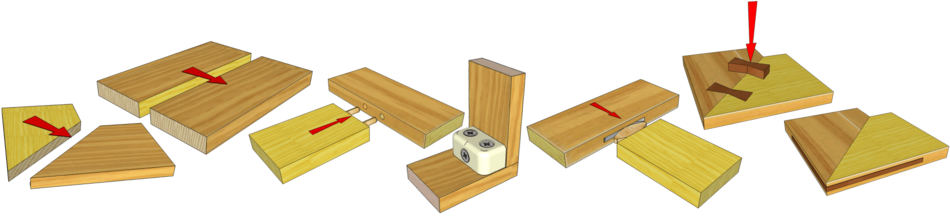

Additionally '''Mitre Joints''' and some '''Widening Joints''' can be categorised as '''Butt Joints''' and, as with all others, can also be reinforced with '''Dowels''', '''Biscuits''' and '''Keys'''. | Additionally '''[[Mitre Joint|Mitre Joints]]''' and some '''[[Widening Joint|Widening Joints]]''' can be categorised as '''Butt Joints''' and, as with all others, can also be reinforced with '''[[Dowel Joint|Dowels]]''', '''[[Knock Down Fittings, Brackets and Plates|Knock-Down Fittings]]''', '''[[Biscuit Joint|Biscuits]]''' and '''[[Keys, Tongues and Slip Feathers|Keys]]''', '''[[Keys, Tongues and Slip Feathers|Tongues]]''' or '''[[Keys, Tongues and Slip Feathers|Slip Feathers]]'''. | ||

</span> | </span> | ||

---- | ---- | ||

[[File:ButtJointReinforcement.png|950px|right]] | |||

<div style="clear: both;"></div> | |||

{{Wood Joints Buyers Guide}} | |||

[[Category:Wood Joints]] | [[Category:Wood Joints]] | ||

Latest revision as of 12:57, 18 February 2017

Description

A Butt Joint is a simple coming together of two edges or faces. The joints can be fixed by simply gluing but more often is reinforced or strengthened before doing so. Butt Joints can be used to widen boards, make frames and create carcasses.

Note:

When used to widen boards, Butt Joints are quite often simply glued and this is known as a Rubbed Joint.

It is important to ensure that the ends of timber forming the joint are cut accurately and Square. This can be achieved off the saw if care is taken using a Tenon Saw and a Mitre Box for example. Alternatively a Precision Mitre Saw or Radial Arm Saw will produce more predictable results. In all cases, scribing the joint lines with a Marking Knife will help to ensure clean edges at the joint face.

Safety Point! Students may only use a Chop Saw or Radial Arm Saw when they have been trained and assessed and the assessment shows that they are competent, and are under appropriate supervision by specifically trained staff.

Reinforcing Butt Joints

- Nails and Screws

The most common way to reinforce a Butt Joint is simply to nail or screw the two pieces together.

Note:

Nails should be angled or 'Dovetailed' for additional grip and screws should be chosen which are twice the length and a thinner gauge when screwing into End Grain.

Where it is not possible to screw directly through one part of the joint to the other (e.g. need to conceal screw heads or lack of access), screws can be sunk into Pockets. These are holes drilled at an angle to the work surface to Counterbore the screw head as shown.

These provide a low cost and quick means of joining together a Butt Jointed frame. They are suitable for coarse joinery work and for assembling frames which are later skinned with Ply, Hardboard, or MDF for example.

Note: Additionally Mitre Joints and some Widening Joints can be categorised as Butt Joints and, as with all others, can also be reinforced with Dowels, Knock-Down Fittings, Biscuits and Keys, Tongues or Slip Feathers.

- Good tools will last a lifetime - buy the best you can afford!