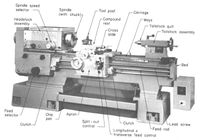

Centre Lathe

From DT Online

The metalworking Centre Lathe is the most universally useful of all machine tools. Most materials can be worked on using a centre lathe but proper maintenance must be undertaken to ensure there is no loss of precision if dust producing materials are turned regularly.

Note: The process of using a lathe is known as ‘turning’ and not ‘lathing’

The work piece is held between centres, gripped in a 3 or 4 jaw chuck, collets or bolted to a faceplate and normally rotated as various machining operations are performed. Common processes include:

| Turning | The process of producing work, or parts of work, which is essentialy cylindrical but may be stepped into various diameters and/or tapered (i.e. ‘solids of revolution’). The workpiece is normally held in a chuck, or a chuck and centre or between centres, perhaps supported by a steady and driven by a carrier. |

| Facing off | This is the process of squaring off the end of a bar held in a chuck but may also be used to produce a flat surface on a casting, for example, which is bolted to a faceplate. |

| Drilling and Boring | Drills can be held in the Tailstock and fed towards a rotating workpiece held in a chuck or bolted to a faceplate. A taper-shank drill chuck is used for parallel shank drills or Morse taper-shank drills are held within its hollow tapered spindle directly. Centre Drills are special purpose short stubby drills used to start a drilling operation or to provide a location for work which is to be held between centres. Boring is the process by which a previously drilled hole is made larger by passing through it a boring tool held in the Toolpost. |

There are many variations on these basic operations. Roles may be reversed and the workpiece held on the Cross Slide in place of the Toolpost, or mounted on a Vertical Slide, and the tools rotated (e.g. a Milling Cutter can be held in the chuck or a Boring Bar held between centres). The Tailstock can be off-set to turn long tapers instead of parallel cylinders and some lathes are able to match the speed of rotation with an automatic feed to cut screwthreads.

Safety Point! Long hair, loose clothing, etc., can become entangled in moving parts and workpieces, chuck keys, broken cutting tools, swarf, etc., can be violently ejected from the lathe. Never try to remove metal swarf or turnings by hand! Never use loose cloths, including emery cloths, to polish items on a lathe.

Lathe operations can be automated or semi-automated for repeated production runs. Turrets holding a sequence of tooling can replace the toolpost and Capstan Lathes enable such arrangements quickly to be slid up and down the lathe bed with auto-changing to the next tool in sequence and fixed depth stops built in. Computer Numerical Controlled (CNC)' lathes, once programmed and tooling set up, can operated wih only minimal attention by a machine operator. The addition of automatic bar feeders and tool caddies for example, allow them to run continously.