Corner Lap Joint: Difference between revisions

From DT Online

(Added process text and images) |

mNo edit summary |

||

| Line 88: | Line 88: | ||

[[File:CornerLapBoxes.png|left|500px]] | [[File:CornerLapBoxes.png|left|500px]] | ||

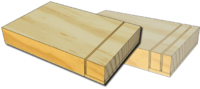

The '''Lap''' can be used not only to hide end grain but also to close off features such as a [https://en.wikipedia.org/wiki/Groove_%28joinery%29 '''Groove'''] cut for a sliding lid or a [https://en.wikipedia.org/wiki/Rabbet '''Rebate'''] cut to receive a box top or backing panel for example. . | The '''Lap''' can be used not only to hide end grain but also to close off features such as a [https://en.wikipedia.org/wiki/Groove_%28joinery%29 '''Groove'''] cut for a sliding lid or a [https://en.wikipedia.org/wiki/Rabbet '''Rebate'''] cut to receive a box top or backing panel for example. | ||

The thickness of the '''Lap''' is varied to suit the depth of '''Groove''' or '''Rebate'''. | |||

[[Category:Wood Joints]] | [[Category:Wood Joints]] | ||

Revision as of 00:57, 1 February 2016

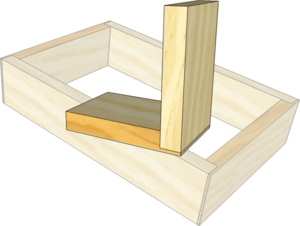

Corner Lap Joints (aka Rebated Butt, Shouldered Corner, or Angle Lap Joint) is useful for joining the corners of boxes, cabinet carcasses and simple drawer fronts for example. It is an improvement on a Butt Joint in that it provides two potential nailing or screwing surfaces and more gluing area.

The thickness of the Lap can depend on whether two nailing surfaces are required for strength, or if it is used only to conceal End Grain or cover the end of a Groove or Rebate for example.

Marking Out

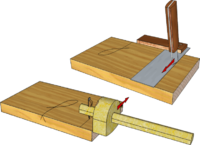

The shoulder is marked along from the end of the work-piece either by striking with a Marking Knife and Try Square or by setting a Cutting Gauge to the timber thickness.

A Marking Gauge can be used to mark the thickness of the Lap.

The scribed lines are pared into a shallow 'V' groove to provide a guide for the Tenon Saw which is used to cut the shoulders.

Scribing the lines serves to ensure the shoulders have an accurate sharp edge where they butt up to the surface of the second piece of timber.

Sawing the Shoulder

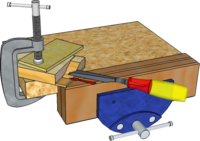

The work-piece is firmly clamped to the bench top and a Tenon Saw is guided by the pared 'V' groove to saw down to the lines marking the Lap.

If additional guidance is required, the scrap piece of timber used to clamp the work-piece can be aligned along the 'V' groove and the saw rubbed alongside it.

It may be necessary when jointing larger pieces of timber to make more than a single saw cut to enable the waste to be removed more easily and accurately.

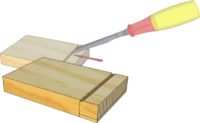

Paring away the waste

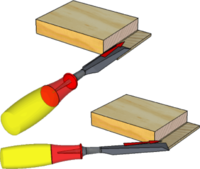

Grip the work firmly by clamping to the bench top and use a Wood Chisel with a Mallet to remove the bulk of the waste

Use Chisels to pare away the remaining waste to create the Lap'.

Grip the blade of the Chisel with one hand (thumb on top) and grip the handle with the other, to push with a slicing action to pare down to the marked lines.Vary directions to cope with any difficult grain.

Note: When paring with a Chisel press the back of the hand or knuckles gripping the blade, against the work-piece to improve control and act as a brake.

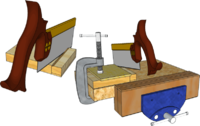

To remove waste and level the Lap on wider boards in particular, a Rebate Plane or Shoulder Plane can be used as shown.

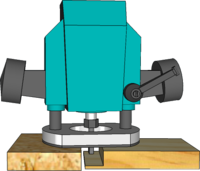

As an alternative to cutting by hand, a Portable Router can be supported on scrap timber equal to the thickness of the work-piece and, with suitable guides in place, the Lap can be machined out.

Uses for a Corner Lap Joint

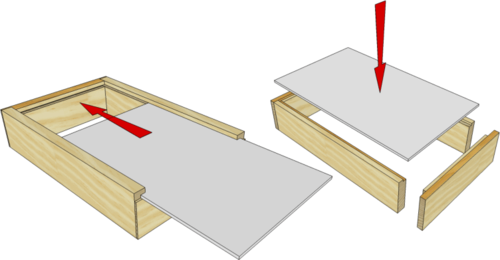

The Lap can be used not only to hide end grain but also to close off features such as a Groove cut for a sliding lid or a Rebate cut to receive a box top or backing panel for example.

The thickness of the Lap is varied to suit the depth of Groove or Rebate.