Drill Press

From DT Online

A Drilling Machine or Drill Press is one of the most common machine tools used in the workshop. Although used primarily for drilling holes, they can be used for a number of machining operations including: reaming, tapping, counterboring, countersinking, and spotfacing. In addition, attachments can be added to enable Mortising, Drum Sanding and some light duty Milling or Routing (but care must be taken not to exert too much sideways force or the chuck may become loosened by vibration)

The most commonly used Drill Press for general use is a Sensitive Drilling Machine and these are suitable for most moderate-to-light duty work. They normally incorporate a belt drive spindle head via double Cone Pulleys which provide a range of speeds (electronic speed controls are also available).

The drill chuck is held usually by a Morse Taper inside a Quill which can be fed vertically via a Rack and Pinion as the spindle is rotated. Hand feeding the tool into the workpiece by this mechanism allows the operator sensitively to to "feel" the cutting action of the tool.

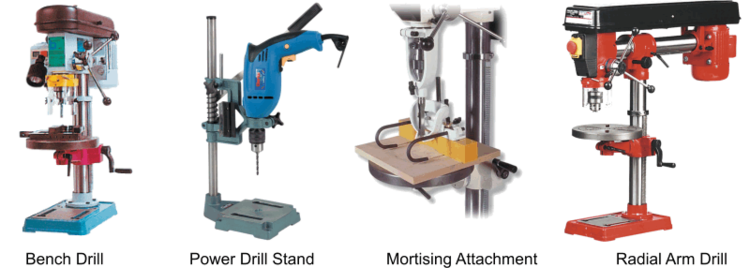

Sensitive Drilling Machines are available as both a Bench Drill and a floor-mounted Pedestal Drill. Both variants usually have tables which can be raised and lowered by a Rack and Pinion mechanism, and some tables can be tilted to allow drilling at an angle. It is possible also to mount a Power Drill in a stand to provide some of the advantages of a Drill Press

Radial Arm Drilling Machine

These are specially useful on larger and heavier parts which may be difficult to position easily, because the the spindle can be positioned directly over the workpiece rather than needing to move the workpiece. The Radial Arm Drilling Machine can often be coupled with a tilting table, or a trunnion table, to drill intersecting and angular holes.