Nails and Pins: Difference between revisions

From DT Online

(Added text) |

mNo edit summary |

||

| Line 1: | Line 1: | ||

[[File:DovetailNailingPunching.png |200px|right]] | [[File:DovetailNailingPunching.png |200px|right]] | ||

Most [https://en.wikipedia.org/wiki/Nail_%28fastener%29 '''Nails'''] are made from [https://en.wikipedia.org/wiki/Drawing_%28manufacturing%29 ''cold drawn''] [https://en.wikipedia.org/wiki/Carbon_steel#Mild_and_low-carbon_steel ''mild steel''] wire. This process improves the strength or wire by [https://en.wikipedia.org/wiki/Work_hardening ''work hardening''] such that '''Nails''' can be driven into timber by use of '''[[Hammers]]'''. | Most [https://en.wikipedia.org/wiki/Nail_%28fastener%29 '''Nails'''] are made from [https://en.wikipedia.org/wiki/Drawing_%28manufacturing%29 ''cold drawn''] [https://en.wikipedia.org/wiki/Carbon_steel#Mild_and_low-carbon_steel ''mild steel''] wire. This process improves the strength or wire by [https://en.wikipedia.org/wiki/Work_hardening ''work hardening''] such that '''Nails''' can be driven into timber by use of '''[[Hammers]]'''. If nails do become bent they can easily be withdrawn using '''[[Pincers and Pry Bars|Pincers]]''' or a '''[[Hammers|Claw Hammer]]''' for example. | ||

Revision as of 16:55, 4 September 2015

Most Nails are made from cold drawn mild steel wire. This process improves the strength or wire by work hardening such that Nails can be driven into timber by use of Hammers. If nails do become bent they can easily be withdrawn using Pincers or a Claw Hammer for example.

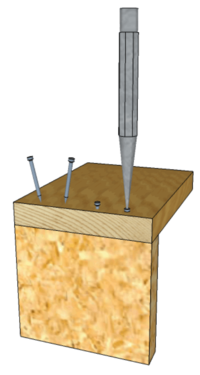

The holding power of nails depends upon Friction and some nails have coatings or grips designed into the body of the nail (i.e. shank) to improve this. In addition, some coatings are applied to improve resistance to corrosion (e.g. Galvanising). Nails may be driven in at opposing angles as shown. This is a process known as Dovetail Nailing and also improves their holding power.

Shown opposite is the use of a Nail Punch. It is good practice on fine work to drive nails in to a few millimeters of the surface then punch them below it. The punched hole can then be filled with Wood Filler.

When using nails in softwoods they can usually be driven in directly but for hardwoods, and sometimes to avoid splitting near the end on any timbers, a small hole may be drilled in the top piece first - or bored with a Bradawl.

Safety Point! Professionals may also use Nail Guns but these are extremely dangerous and not suitable for school use.