G Cramp: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 6: | Line 6: | ||

---- | ---- | ||

<span style="color: green">'''Notes:''' | <span style="color: green">'''Notes:''' | ||

Although called a G Cramp because they resemble the letter, they are more conveniently used upside down where possible (they are also known as C Clamps). | Although called a G Cramp because they resemble the letter, they are more conveniently used upside down where possible ''(they are also known as C Clamps)''. | ||

Place pieces of scrap wood between cramps and workpiece to spread the load and prevent surface damage. | Place pieces of scrap wood between cramps and workpiece to spread the load and prevent surface damage. | ||

</span> | </span> | ||

Revision as of 08:52, 28 July 2015

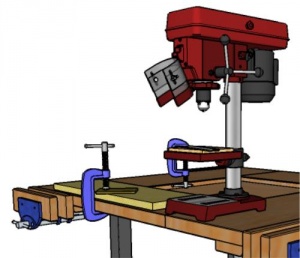

G Cramps are used to hold together workpieces while gluing or to hold work firmly to a bench or machine whilst it is being worked on.

G Camps are available typically in a range of sizes with capacities to cramp materials from 50mm up to 300mm thickness.

Notes: Although called a G Cramp because they resemble the letter, they are more conveniently used upside down where possible (they are also known as C Clamps). Place pieces of scrap wood between cramps and workpiece to spread the load and prevent surface damage.

Edging Cramps have an additional screw at the side which makes them useful when gluing edging or lipping to the edge of boards for example. Deep Throat G Cramps allow materials to be cramped further in from their edges.

Modern equivalents include F Clamps, short Bar Clamps and various single-handed or ‘quick-clamp’ variations.