Tenon Saw: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 1: | Line 1: | ||

[[File:CuttingTenons.jpg|300px|right]] | [[File:CuttingTenons.jpg|300px|right]] | ||

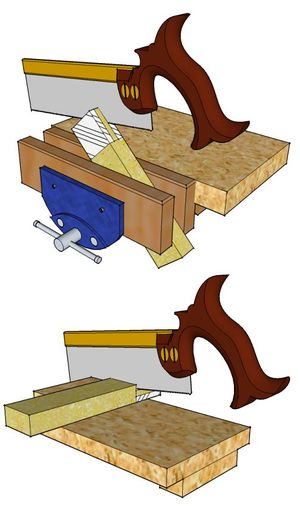

[http://en.wikipedia.org/wiki/Backsaw '''Tenon saws'''] are a '''[[backsaw]]''', typically 250mm or 300mm long, with 10 to 14 teeth per inch ''[[Teeth per Inch|(TPI)]]''. They are used for general woodwork and, in particular, to cut tenons as part of a [http://en.wikipedia.org/wiki/Mortise_and_tenon '''mortise and tenon joint'''], as shown. | [http://en.wikipedia.org/wiki/Backsaw '''Tenon saws'''] are a '''[[backsaw]]''', typically 250mm or 300mm long, with 10 to 14 teeth per inch ''[[Teeth per Inch|(TPI)]]''. They are used for general woodwork and, in particular, to cut tenons as part of a [http://en.wikipedia.org/wiki/Mortise_and_tenon '''mortise and tenon joint'''], as shown. | ||

After marking out with try square, mortise gauge and marking knife, the workpiece is held in a vice such that two lines can be seen and sawn accurately along. Work should be repositioned to ensure that the saw cuts horizontally and the tenon is always on the user's side of the blade - where it can be seen. After cutting two diagonals the work is positioned vertically and the saw completes cutting down the ''‘cheeks’''. | After marking out with try square, mortise gauge and marking knife, the workpiece is held in a vice such that two lines can be seen and sawn accurately along. Work should be repositioned to ensure that the saw cuts horizontally and the tenon is always on the user's side of the blade - where it can be seen. After cutting two diagonals the work is positioned vertically and the saw completes cutting down the ''‘cheeks’''. | ||

Revision as of 21:37, 2 October 2015

Tenon saws are a backsaw, typically 250mm or 300mm long, with 10 to 14 teeth per inch (TPI). They are used for general woodwork and, in particular, to cut tenons as part of a mortise and tenon joint, as shown.

After marking out with try square, mortise gauge and marking knife, the workpiece is held in a vice such that two lines can be seen and sawn accurately along. Work should be repositioned to ensure that the saw cuts horizontally and the tenon is always on the user's side of the blade - where it can be seen. After cutting two diagonals the work is positioned vertically and the saw completes cutting down the ‘cheeks’.

Note: Work is positioned such that the saw is pushing down on to the grain fibres and not plucking them up. Although not common, tenon saws are available with ripsaw teeth for this cutting along the grain.

Tenon ‘shoulders’ are first scribed with a marking knife to ensure a clean edge, then cut against a bench hook as shown. The bench hook may be held in a vice - as can the whole workpiece if preferred, instead of a bench hook.