Blacksmiths' Tools: Difference between revisions

From DT Online

m Corrected Link |

Added Template |

||

| Line 1: | Line 1: | ||

[[File:Blacksmith's tools - geograph.org.uk - 1483374.jpg|Blacksmith's tools - geograph.org.uk - 1483374|300px|right]] | [[File:Blacksmith's tools - geograph.org.uk - 1483374.jpg|Blacksmith's tools - geograph.org.uk - 1483374|300px|right]] | ||

__TOC__ | |||

=====Description===== | |||

The equipment for hand forging is relatively simple. Since the process in essence is a hammering operation on a heated piece of metal, '''[[:Category:Hammers|Hammers]]''' are required of various weights up to and including a '''Sledge Hammer''' which would be wielded by a Smith's assistant or [https://en.wikipedia.org/wiki/Blacksmith#Blacksmith.27s_striker '''Striker'''] - although really heavy hammering would be done by a [https://en.wikipedia.org/wiki/Trip_hammer '''Trip Hammer'''] or [https://en.wikipedia.org/wiki/Power_hammer '''Power Hammer'''] of some type - including the [https://en.wikipedia.org/wiki/Steam_hammer '''Steam Hammer'''], famously patented in 1842 by [https://en.wikipedia.org/wiki/James_Nasmyth '''James Nasmyth''']. | The equipment for hand forging is relatively simple. Since the process in essence is a hammering operation on a heated piece of metal, '''[[:Category:Hammers|Hammers]]''' are required of various weights up to and including a '''Sledge Hammer''' which would be wielded by a Smith's assistant or [https://en.wikipedia.org/wiki/Blacksmith#Blacksmith.27s_striker '''Striker'''] - although really heavy hammering would be done by a [https://en.wikipedia.org/wiki/Trip_hammer '''Trip Hammer'''] or [https://en.wikipedia.org/wiki/Power_hammer '''Power Hammer'''] of some type - including the [https://en.wikipedia.org/wiki/Steam_hammer '''Steam Hammer'''], famously patented in 1842 by [https://en.wikipedia.org/wiki/James_Nasmyth '''James Nasmyth''']. | ||

=====Features and Applications===== | |||

A wide variety of '''Tongs''' are needed to hold the hot metal whilst it is being worked and various tools to cut, shape or punch the metal are either held in the anvil's '''Hardie Hole''' or include a handle - often to be held in position as a [https://en.wikipedia.org/wiki/Blacksmith#Blacksmith.27s_striker '''Striker'''] provides the neccessary hammer blows. | A wide variety of '''Tongs''' are needed to hold the hot metal whilst it is being worked and various tools to cut, shape or punch the metal are either held in the anvil's '''Hardie Hole''' or include a handle - often to be held in position as a [https://en.wikipedia.org/wiki/Blacksmith#Blacksmith.27s_striker '''Striker'''] provides the neccessary hammer blows. | ||

| Line 8: | Line 14: | ||

Traditionally, [https://en.wikipedia.org/wiki/Blacksmith '''Blacksmiths'''] and [https://en.wikipedia.org/wiki/Farrier '''Farriers'''] would often make their own '''Tongs''' and other hand tools to suit the particular work in hand. | Traditionally, [https://en.wikipedia.org/wiki/Blacksmith '''Blacksmiths'''] and [https://en.wikipedia.org/wiki/Farrier '''Farriers'''] would often make their own '''Tongs''' and other hand tools to suit the particular work in hand. | ||

---- | ---- | ||

| Line 114: | Line 118: | ||

The initial punched hole can be further shaped and brought to size by driving various '''[[:Category:Punches|Drifts]]''' through the hot metal. | The initial punched hole can be further shaped and brought to size by driving various '''[[:Category:Punches|Drifts]]''' through the hot metal. | ||

{{Blacksmiths Buyers Guide}} | |||

[[Category:Blacksmithing]] | [[Category:Blacksmithing]] | ||

Latest revision as of 12:09, 11 August 2016

Description

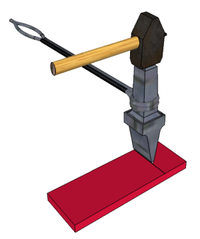

The equipment for hand forging is relatively simple. Since the process in essence is a hammering operation on a heated piece of metal, Hammers are required of various weights up to and including a Sledge Hammer which would be wielded by a Smith's assistant or Striker - although really heavy hammering would be done by a Trip Hammer or Power Hammer of some type - including the Steam Hammer, famously patented in 1842 by James Nasmyth.

Features and Applications

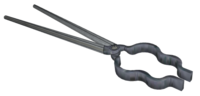

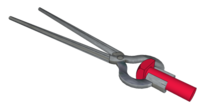

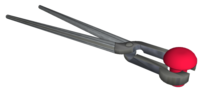

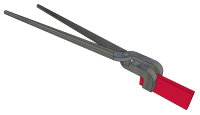

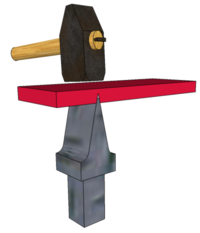

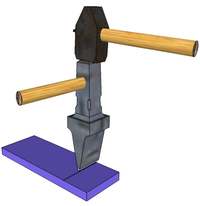

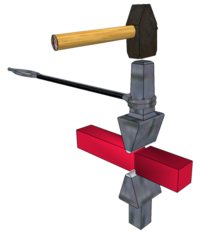

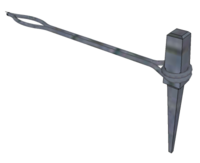

A wide variety of Tongs are needed to hold the hot metal whilst it is being worked and various tools to cut, shape or punch the metal are either held in the anvil's Hardie Hole or include a handle - often to be held in position as a Striker provides the neccessary hammer blows.

Traditionally, Blacksmiths and Farriers would often make their own Tongs and other hand tools to suit the particular work in hand.

Tongs

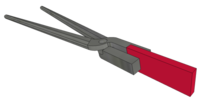

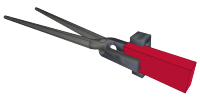

Tongs can be self-made or commercially available ‘standard’ designs heated and re-forged to suit the work in hand. Many designs need to be available in a range of sizes such that the workpiece is gripped firmly and evenly along the length of the jaws.

| Flat Bit Tongs | For holding flat strips of metal - different widths between the jaws are needed for different thicknesses of metal. |  |

| Box Tongs | Similar useage to Flat Bit Tongs but with a lip on each side to prevent narrower strips of metal from slipping round. |  |

| Hollow Bit Tongs | Made of various sizes to hold round metal stock. The curve inside the Tongs jaws should always be a little less than that of the work to ensure it is gripped tightly. |  |

| Pick-up Tongs (aka ‘Dandy’) | Often used by the Striker and to pick up tools and small pieces generally. |  |

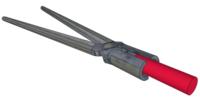

| Bolt or Round Mouth Tongs | Used to grip round bar and for pieces having a larger end than the body, such as bolts, etc. |  |

| Rivet Tongs | Also useful when needing to hold round bar vertically (e.g. when ‘Upsetting’ or ‘Jumping Up’ a short length of bar - see The Blacksmith's Craft for an explanation of this process). |  |

| Side Mouth Tongs | Available in various sizes and used for gripping a given thickness of hot metal at its edges or for work that may be too long to be held in an ordinary pair of flat tongs - the bits are bent at right angles so that the work can pass by the joints. |  |

| Ring, Hoop or Crooked Bit Tongs | Useful for handling rings of flat metal and for holding metal strips while bending around their width. |  |

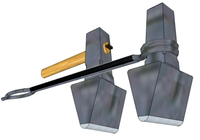

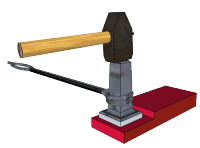

Cutting Tools

| Hot Set | Used to cut hot metal. Most Blacksmiths' tools may have Rodded handles as shown, or be fitted with wooden shafts. |  |

| Hardie | This fits into the Anvil's Hardie Hole and is used for cutting though hot metal |  |

| Cold Set | These are Hardened and Tempered to enable them to cut cold metal without blunting. Some Blacksmiths prefer wooden shafts for such tools on the basis that it gives more control.

Note: Cutting metal cold should always be done on the Anvil Table which is left soft for this purpose and not on the hardened Anvil Face Blacksmiths will also use hand-held Cold Chisels for detailed work. |

|

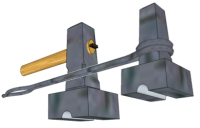

Shaping Tools

| Top Fuller | Used with a Bottom Fuller quickly to thin or lengthen hot metal or to forge a rounded ‘neck’ against a shoulder to avoid a sharp corner and maintain the fibre or ‘grain’ of the metal - this is the reason nearly all the Smith's tools are rounded, since sharp angles and corners are a source of weakness and can produce a Stress Concentration |  |

| Bottom Fuller | Fits into Anvil hardie hole and is used with a Top Fuller to increase metal in length. |  |

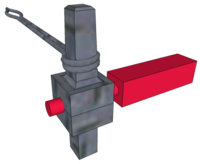

| Top Swage | Used with a Bottom Swage or Swage Block for reducing or drawing down round bar. |  |

| Bottom Swage | Used with a Top Swage for reducing or drawing down round bar. |  |

| Flatter | For finishing wide surfaces in conjunction with the Anvil workface. Helps remove hammer markings. |  |

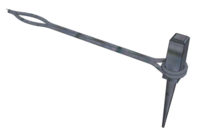

Punching Tools

| Round | Used to make round holes in hot metal (e.g. to make holes in hammer heads for shafts) |  |

| Square | Used to make square holes in hot metal. |  |

The initial punched hole can be further shaped and brought to size by driving various Drifts through the hot metal.

|

|

|

|

|

|

|

|

| Blacksmiths Tongs |

Hardened Steel Anvil 30kg |

Draper Anvil |

Swage Block |

FatMax Blacksmiths Hammer |

Blacksmiths Forge/Knife Forge |

Leather Workshop Apron |

Leather Welders Gloves |