3D Printers: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| Line 10: | Line 10: | ||

=====Features and Applications===== | =====Features and Applications===== | ||

A variety of '''Additive Manufacturing''' techniques have been developed ''(e.g. [https://en.wikipedia.org/wiki/Stereolithography '''Stereolithography'''], [https://en.wikipedia.org/wiki/Direct_metal_laser_sintering '''Direct Metal Laser Sintering (DMLS)'''] and even [https://en.wikipedia.org/wiki/Construction_3D_printing '''Construction 3D Printing'''] which prints buildings with concrete!)'' but the method most commonly available for schools and hobbyists is based on building up a model from layers of a plastics filament and fusing them together ''(i.e. [https://en.wikipedia.org/wiki/Fused_deposition_modeling '''Fused Deposition Modeling'''])'' in which a coil of plastics ‘wire’ is fed through a computer controlled heated nozzle. | A variety of '''Additive Manufacturing''' techniques have been developed ''(e.g. [https://en.wikipedia.org/wiki/Stereolithography '''Stereolithography (STL)'''], [https://en.wikipedia.org/wiki/Direct_metal_laser_sintering '''Direct Metal Laser Sintering (DMLS)'''] and even [https://en.wikipedia.org/wiki/Construction_3D_printing '''Construction 3D Printing'''] which prints buildings with concrete!)'' but the method most commonly available for schools and hobbyists is based on building up a model from layers of a plastics filament and fusing them together ''(i.e. [https://en.wikipedia.org/wiki/Fused_deposition_modeling '''Fused Deposition Modeling (FDM)'''])'' in which a coil of plastics ‘wire’ is fed through a computer controlled heated nozzle. | ||

Revision as of 17:23, 14 August 2016

Description

Most traditional manufacturing processes for single components are based on the removal (or subtraction) of materials from standard bar stock for example (e.g. by drilling, milling or turning on a lathe). 3D Printing is the general term now used for Additive Manufacturing (AM) which, by contrast, creates objects by a process of fusing together layers of material to build up a 3D product.

Features and Applications

A variety of Additive Manufacturing techniques have been developed (e.g. Stereolithography (STL), Direct Metal Laser Sintering (DMLS) and even Construction 3D Printing which prints buildings with concrete!) but the method most commonly available for schools and hobbyists is based on building up a model from layers of a plastics filament and fusing them together (i.e. Fused Deposition Modeling (FDM)) in which a coil of plastics ‘wire’ is fed through a computer controlled heated nozzle.

Software

The control or driver software for 3D Printers accepts CAD models in the STL File Format. This file-type converts the surface of a 3D CAD model into a series of triangluar facets which the driver software can then convert into a series of thin layers or ‘slices’ and produce a G-code type file to control the printer.

The STL File can be exported from most modern CAD applications (e.g. FreeCAD) or 3D Modelling sofware such as Tinkercad, 123D Design or SketchUp Make (with SketchUp STL extension) all of which are free to download and use. Alternatively, a simple Internet Search for <STL Files>, for example, will reveal many sources for existing models which can be downloaded, edited and used.

Most CAD and 3D Modelling applications will produce some errors in the output STL file (e.g. around holes or intersections) and so loading it first into verification software such as Meshmixer (a free program from Autodesk) will check the faceting and fix any surface flaws.

Note: Although school use of 3D printing may be limited to plastics and similar materials, models created in wax can then be used in a Lost Wax Casting process to create protoypes in metals such as Aluminium and various Zinc based alloys (e.g. Kayem or Mazac).

Injection Moulding can be less expensive when manufacturing large quantities of plastics products, but Additive Manufacturing is generally more flexible and less expensive when producing relatively small quantities or single prototypes - hence the alternative name of Rapid Prototyping.

Safety Point!

- Fully enclosed machines with interlocks are advised for school use.

- Only Lasers with the laser beam totally enclosed should be used in schools and an interlock provided to prevent operation unless the laser is enclosed - check Laser Safety with supplier.

- Always isolate any CNC machine before adjusting tools or work piece and ensure hands are well clear of the table before switching on - when the program runs : the cutter will move!

|

|

|

|

|

|

|

| GenMitzu CNC Router |

Trend CNC Machine Engraver |

GOWE CO2 Laser Cutting Machine |

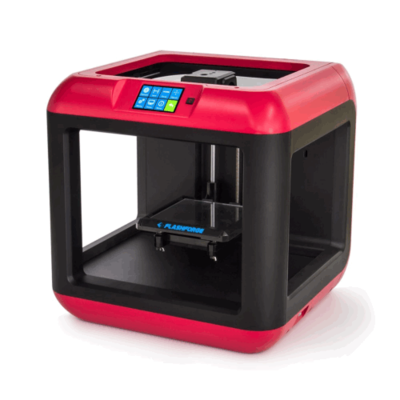

Flashforge 3D Printer |

Sign Cutter Plotter |

Scanner |

Computerised Digital Sewing Machine |