Workshop Heat Area Example 1: Difference between revisions

From DT Online

(Created article) |

m (Added Note) |

||

| Line 9: | Line 9: | ||

* It should be located with at least one external wall and ideally, but not essentially, with access to outside | * It should be located with at least one external wall and ideally, but not essentially, with access to outside | ||

---- | |||

<span style="color: green">'''Note:''' | |||

The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them. | |||

</span> | |||

---- | |||

[[File:HeatArea1.png|800px|center]] | [[File:HeatArea1.png|800px|center]] | ||

Revision as of 20:25, 15 February 2017

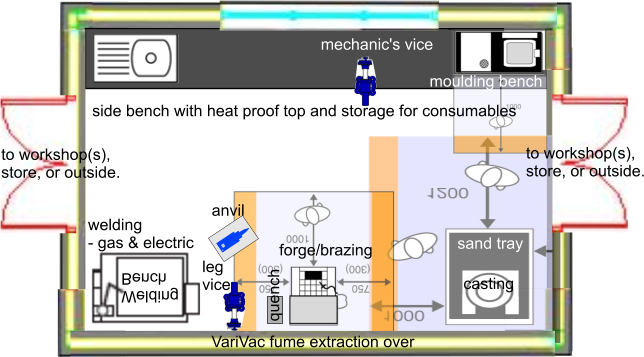

A Heat Area contains equipment for heating, forming and casting metals The Heat Area may be a space within a workshop, a separate bay off a workshop, or a separate room.

If in a separate area and of sufficient size, the Heat Area may also be a good location for metal forming equipment such as folding bars, bench shears, tube benders and bending rolls.

- Where possible, the Heat Area can be a shared resource between a group of workshops.

- Water should be provided but must be as far as possible away from the casting equipment.

- It must be well ventilated with fume extraction - to include localised extaction over welding and casting.

- It should be located with at least one external wall and ideally, but not essentially, with access to outside

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.