Resistant Materials Workshop Example 1: Difference between revisions

From DT Online

Created article |

m Added Product |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 10: | Line 10: | ||

The workshop may also have shared Heat Area adjacent in which case will not need a Brazing Hearth or fume extraction - it could also link through to a shared machining area and/or a collaborative project space - this may remove the need for a metal lathe and also increase the use of mobile equipment on braked trolleys | The workshop may also have shared Heat Area adjacent in which case will not need a Brazing Hearth or fume extraction - it could also link through to a shared machining area and/or a collaborative project space - this may remove the need for a metal lathe and also increase the use of mobile equipment on braked trolleys | ||

---- | |||

<span style="color: green">'''Note:''' | |||

The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them. | |||

</span> | |||

---- | |||

[[File:ResMats1.png|800px|center]] | [[File:ResMats1.png|800px|center]] | ||

{| | |||

|- | |||

! Description | |||

! Code | |||

! Notes | |||

! Image | |||

|- | |||

| '''Technology Bench''' | |||

| LFTAB20 | |||

| 1200mm x 1200mm and also 1000mm x 1000mm sizes available with optional vice rack and/or cupboard - LFSPF33 is an alternative. One bench shown split to make half adjustable height with two vices. | |||

| [[File:Bench.png|100px|right]] | |||

|- | |||

| '''Braked Trolley''' | |||

| LFTEB93 | |||

| most bench-mounted equipment can also be fixed to a trolley with braked castors to aid flexibility by enabling specialist equipment to be shared between adjacent spaces. | |||

| <dtamazon product="B00X5MMNN2" type="image">Mobile Workbench-Tool Box Tool Chest with Roller Tool Cabinet 6 Drawers Solid Design</dtamazon> | |||

|- | |||

| '''Bandsaw''' | |||

| FESEQ339 | |||

| bolt down next to materials store room with good 'run-off' space as shown. | |||

| <dtamazon product="B005C9AET6" type="image">Charnwood W730 14'' Woodworking Bandsaw</dtamazon> | |||

|- | |||

| '''Line Bender''' | |||

| LESEQ299 | |||

| used to line bend sheets of acrylic - usually positioned on a side bench but can also go on workbench or trolley | |||

| [[File:ClarkeStripHeater.jpg|125px|right]] | |||

|- | |||

| '''Scroll Saw''' | |||

| LESEQ320 | |||

| can be mounted on bench, a braked trolley or mounting board fixed in a vice. | |||

| <dtamazon product="B00E6NH36G" type="image">Scheppach SD1600F 230V Variable Speed Hobby Scroll Saw with 64Piece Accessory Set </dtamazon> | |||

|- | |||

| '''Bench Drill''' | |||

| FESEQ472 | |||

| position away from corners to avoid crowding in use and bolt to side bench top. | |||

| <dtamazon product="B00142B88Q" type="image">Draper 42640 230-Volt 650-Watt 16-Speed Heavy-Duty Bench Drill</dtamazon> | |||

|- | |||

| '''Bag Store''' | |||

| LFSTR62 | |||

| almost always needed in a practical room to avoid danger of bags on floor. | |||

| <dtamazon product="B01N1EXQVF" type="image">Songmics 9 Compartments Standing Storage Rack Shelving Organizer Units, Capacity/shelf:15 kg, Black LSN33H </dtamazon> | |||

|- | |||

| '''DT Storage Wall''' | |||

| FFFFU60 | |||

| Fitted out to take small tools etc. and includes IWB tray unit, magnetic WB, plus pull-out fully serviced teacher caddy/desk. Position 90deg to windows. | |||

| [[File:DT TeachingWall5.png|125px|right]] | |||

|- | |||

| '''Waste Bin''' | |||

| LEOTR487 | |||

| in workshops needed for: paper, metal, wood, plastics, glass, plus non-recycle. | |||

| <dtamazon product="B00GY8I2C0" type="image">VonHaus 45L Litre Stainless Steel 3 in 1 Compartment Indoor Recycling Rubbish Pedal Bin</dtamazon> | |||

|- | |||

| '''Thermoforming Centre''' | |||

| LESEQ635 | |||

| used for thermoforming plastics - a mobile unit - needs only a 'parking place' plus access to 13 Amp power | |||

| [[File:ThermoFormingCentre.png|100px|right]] | |||

|- | |||

| '''Trimmer''' | |||

| LESEQ324 | |||

| mount on braked trolley or side bench - used to cut away waste from vacuum formings for example | |||

| [[File:Trimmer.png|75px|right]] | |||

|- | |||

| '''Double-ended Polisher''' | |||

| LEOTR487 | |||

| either bench mounted or fixed to floor stand | |||

| <dtamazon product="B01E3FFH8M" type="image">GR-TECH Instrument ® Dental Grinder Buffing Polishing Machine 220V 1400rpm </dtamazon> | |||

|- | |||

| '''Bandfacer''' | |||

| FESEQ304 | |||

| should be fixed near centre of wall to avoid crowding - includes own dust extraction | |||

| [[File:Bandfacer.png|75px|right]] | |||

|- | |||

| '''Lo-Temp Casting Kiln''' | |||

| FESEQ336 | |||

| used for casting in pewter and other low melting point alloys - position near heat proof top on side benching | |||

| [[File:507125 xl.png|75px|right]] | |||

|- | |||

| '''Pillar Drill''' | |||

| FESEQ301 | |||

| position near centre of wall to avoid crowding - MUST be bolted down - head can be height adjusted to accommodate wheelchair users - esp. if 2 machines | |||

| <dtamazon product="B00142GPBG" type="image">Draper 42642 12-Speed Heavy-Duty Drill Press</dtamazon> | |||

|- | |||

| '''Metal Turning Lathe''' | |||

| FESEQ633 | |||

| bolt securely to the floor. | |||

| <dtamazon product="B007JC93F0" type="image">CLARKE METAL LATHE 6 SPEED with SCREW CUTTING 430mm</dtamazon> | |||

|- | |||

|} | |||

[[Category:Accommodating Design and Technology in Secondary Schools]] | [[Category:Accommodating Design and Technology in Secondary Schools]] | ||

Latest revision as of 18:08, 20 February 2017

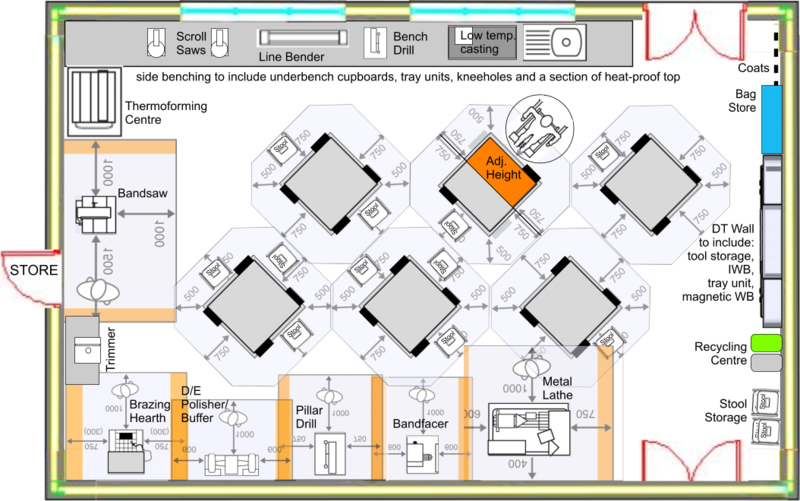

Here students will work in a range of materials including metals, wood and plastics to create mainly domestic products.

These will be the main workshops used by younger pupils (up to KS3) but also to service GCSE Product Design courses.

There will most often be a storeroom adjacent plus doors into the workshop and a door to the outside.

The workshop may also have shared Heat Area adjacent in which case will not need a Brazing Hearth or fume extraction - it could also link through to a shared machining area and/or a collaborative project space - this may remove the need for a metal lathe and also increase the use of mobile equipment on braked trolleys

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.