Phase Diagrams: Difference between revisions

From DT Online

(Created article) |

mNo edit summary |

||

| Line 31: | Line 31: | ||

=====Phase Diagram for Lead/Tin Eutectic Alloy===== | =====Phase Diagram for Lead/Tin Eutectic Alloy===== | ||

[https://en.wikipedia.org/wiki/Phase_diagram#Binary_phase_diagrams '''Phase Diagrams'''] combine the information from the [https://en.wikipedia.org/wiki/Cooling_curve '''Cooling Curves'''] of mixtures of metals with metals and with other elements to create a chart which is used to show the behaviours of '''[[Alloy|Alloys]]''' as they change phases | [https://en.wikipedia.org/wiki/Phase_diagram#Binary_phase_diagrams '''Phase Diagrams'''] combine the information from the [https://en.wikipedia.org/wiki/Cooling_curve '''Cooling Curves'''] of mixtures of metals with metals and with other elements to create a chart which is used to show the behaviours of '''[[Alloy|Alloys]]''' as they change phases between [https://en.wikipedia.org/wiki/Solid '''Solid'''] to [https://en.wikipedia.org/wiki/Liquid '''Liquid'''] states. | ||

The [https://en.wikipedia.org/wiki/Phase_diagram#Binary_phase_diagrams '''Phase Diagram'''] for the '''[[Eutectic Alloy]]''' of 62% '''Tin''' & 38% '''Lead''' shows that at 183<sup>0</sup>C it changes from : [https://en.wikipedia.org/wiki/Liquid '''Liquid'''] to [https://en.wikipedia.org/wiki/Solid '''Solid'''] without going through any ‘pasty’ stage which makes it ideal for Tinman's Solder. | |||

[[File:SteelPhaseDiagram.png|300px|right|Lead Tin Alloy Phase Diagram]] | |||

=====Phase Diagram for Carbon Steel===== | |||

As [https://en.wikipedia.org/wiki/Carbon_steel '''Carbon Steels'''] are heated towards their melting point their '''[[Crystalline Structures]]''' change from a '''[[Crystalline Structures|Body Centred Cubic]]''' structure to a '''[[Crystalline Structures|Face Centred Cubic]]''' structure. A consequence of this is that '''Iron''' heated above this '''Critical Point''' can absorb a lot more '''Carbon''' within a '''[[Crystalline Structures|FCC]]''' structure. | |||

[https://en.wikipedia.org/wiki/Ferrite_(iron) '''Ferrite'''] can be taken as just another name for '''Iron''' and, at room temperatures, it can absorb only a very small amount of '''Carbon''' ''(i.e. about 0.006%)'' within its '''[[Crystalline Structures|BCC]]''' structure. But immediately above 723°C '''Iron''' changes to a '''[[Crystalline Structures|FCC]]''' structure called [https://en.wikipedia.org/wiki/Austenite '''Austenite'''] and now can absorb up to 0.83% carbon - and this increases with rising temperature. [https://en.wikipedia.org/wiki/Austenite '''Austenite'''] can only exist at this elevated temperature and so as it cools all the extra '''Carbon''' has to go somewhere. | |||

The [https://en.wikipedia.org/wiki/Phase_diagram#Binary_phase_diagrams '''Phase Diagram'''] shows that for '''Steels''' with less than 0.76% '''Carbon''' the mix solidifies into [https://en.wikipedia.org/wiki/Ferrite_(iron) '''Ferrite'''] and a layered structure called [https://en.wikipedia.org/wiki/Pearlite '''Pearlite'''] if it is allowed to cool slowly. If cooled quickly, or '''Quenched''' a fine grained [https://en.wikipedia.org/wiki/Pearlite '''Pearlite'''] will result, | |||

[[Category:Materials and Components]] | [[Category:Materials and Components]] | ||

Revision as of 20:23, 22 March 2017

Phase Diagrams are charts which show how different Phases can exist together under certain conditions (e.g. the temperature range at which water and ice can exist together in slushy conditions). Three obvious Phases are the three states of matter: Solid, Liquid, and Gas but different Phases also exist when two or more liquids or solids come into contact with each other for example.

In Metallurgy we are normally concerned with just Solid and Liquid phases plus situations where these might exist together. The temperature line above which everything is Liquid is known as the Liquidus and the line below which everything is Solid is known as the [https://en.wikipedia.org/wiki/Solidus_(chemistry) Solidus.

Cooling Curves

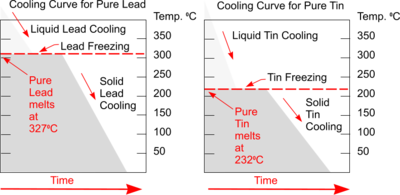

Plotting a graph of Temperature and Time as liquid metal cools will produce a Cooling Curve. Such graphs serve to illustrate the behaviour of metal as it cools and what changes occur at different temperatures.

Typical Cooling Curves for pure metals will be a stepped graph as shown. Heat is being lost throughout the process but at the point of freezing the temperature doesn't fall because the freezing process will liberate heat at exactly the same rate that it is being lost to the surroundings.

This is the result of energy being released when new atomic bonds are formed formed (e.g changing states from Liquid to Solid Lead or Tin).

The Cooling Curve for an Alloy is more complicated and reveals interesting behaviours as solidification takes place.

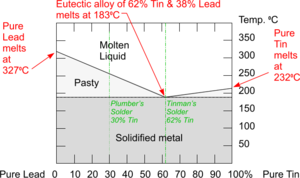

With this particular Alloy, nothing happens at the normal freezing point of Lead because the addition of Tin has lowered this. Some solidification of Lead starts around 2500C but Tin remains liquid and there is not enough energy released to cause the Cooling Curve to go horizontal - although it does flatten out because cooling slows down a little.

The temperature stops falling at 1830C when both the Tin and Lead are starting to freeze. Once everything has solidified, the temperature continues to fall.

Phase Diagram for Lead/Tin Eutectic Alloy

Phase Diagrams combine the information from the Cooling Curves of mixtures of metals with metals and with other elements to create a chart which is used to show the behaviours of Alloys as they change phases between Solid to Liquid states.

The Phase Diagram for the Eutectic Alloy of 62% Tin & 38% Lead shows that at 1830C it changes from : Liquid to Solid without going through any ‘pasty’ stage which makes it ideal for Tinman's Solder.

Phase Diagram for Carbon Steel

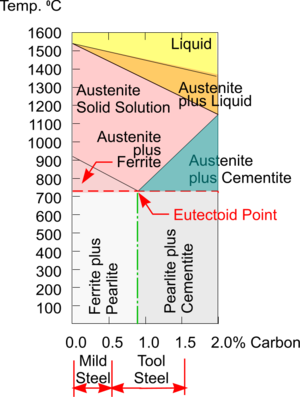

As Carbon Steels are heated towards their melting point their Crystalline Structures change from a Body Centred Cubic structure to a Face Centred Cubic structure. A consequence of this is that Iron heated above this Critical Point can absorb a lot more Carbon within a FCC structure.

Ferrite can be taken as just another name for Iron and, at room temperatures, it can absorb only a very small amount of Carbon (i.e. about 0.006%) within its BCC structure. But immediately above 723°C Iron changes to a FCC structure called Austenite and now can absorb up to 0.83% carbon - and this increases with rising temperature. Austenite can only exist at this elevated temperature and so as it cools all the extra Carbon has to go somewhere.

The Phase Diagram shows that for Steels with less than 0.76% Carbon the mix solidifies into Ferrite and a layered structure called Pearlite if it is allowed to cool slowly. If cooled quickly, or Quenched a fine grained Pearlite will result,