Creasing Iron: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 5: | Line 5: | ||

'''Creasing Irons''' are used in '''[[:Category: | '''Creasing Irons''' are used in '''[[:Category:Sheet Metalwork|Tinsmithing]]''' particularly to help form a rolled or '''[[Wired Edge]]''' to a piece of '''Tinplate''' work. | ||

| Line 13: | Line 13: | ||

[[Category:Stakes]] | [[Category:Stakes]] | ||

[[Category: | [[Category:Sheet Metalwork]] | ||

Latest revision as of 17:23, 28 May 2017

Description

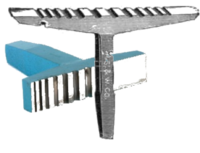

A Creasing Iron may be considered a small version of a Swage Block. It can be held in a Vice, Bench Socket or the Hardie Hole of an Anvil.

Creasing Irons are used in Tinsmithing particularly to help form a rolled or Wired Edge to a piece of Tinplate work.

- Traditional Boxwood Mallets are now largely superceded by Nylon, PVC or rubber faced hammers and mallets for general work. They are available in a range of diameters and weights.

- Carpenters' Mallets with a head size of 4-5 inches (100mm - 125mm) are a suitable size for most work in Design and Technology.

- Carving Mallet heads are commonly made from Beech but Lignum Vitea heads are considered better because they are heavier. They may now be hard to find. A modern alternative is to use Polyurethane for the heads (Bronze or Brass also used). A good general size head weight for light work would be approximately 450 grams or less, and for general work, 800 grams is more suitable.

- Bossing Mallets are sized by head diameter (35, 50, 60, or 75mm). The smaller sizes are used for art metalwork and the larger sizes are for shaping and stretching sheet metal and soft roofing materials such as lead.

|

|

|

|

|

| Nylon Hammer |

Rubber Mallet |

Carpenters Mallet |

Carvers Mallet |

Rawhide Mallet |