Safe Edge: Difference between revisions

From DT Online

Created article |

mNo edit summary |

||

| Line 11: | Line 11: | ||

=====Making the Joint===== | =====Making the Joint===== | ||

* | * Mark out the width of the [https://en.wikipedia.org/wiki/Hemming_and_seaming '''Hem''']. | ||

* Fold initially to an acute angle using '''[[Folding Bars]]''' and '''[[Hatchet Stake]]''' or '''[[Bench Folder]]'''. | * Fold initially to an acute angle using '''[[Folding Bars]]''' and '''[[Hatchet Stake]]''' or '''[[Bench Folder]]'''. | ||

* Use a '''[[Boxwood Mallet|Boxwood]]''' or '''[[Rawhide Mallet]]''' to beat it flat down on to a '''[[Bench Block]]''' or similar surface. | * Use a '''[[Boxwood Mallet|Boxwood]]''' or '''[[Rawhide Mallet]]''' to beat it flat down on to a '''[[Bench Block]]''' or similar surface. | ||

Latest revision as of 09:59, 30 May 2017

Description

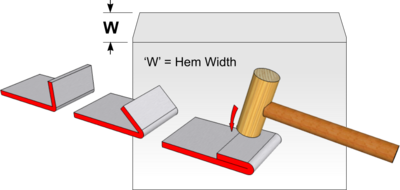

The edges of thin sheet metals can be extremely sharp and dangerous, especially when cut, so often need to be made 'safe'. The simplest way to achieve this is to fold the metal over on itself along the edge. This is known as making a Safe Edge (or Hem).

Making the Joint

- Mark out the width of the Hem.

- Fold initially to an acute angle using Folding Bars and Hatchet Stake or Bench Folder.

- Use a Boxwood or Rawhide Mallet to beat it flat down on to a Bench Block or similar surface.

Note: Use a Mallet and not a Hammer to avoid stretching the metal as it is struck (this would cause the edge to curl and distort).