Pneumatic Cylinder: Difference between revisions

From DT Online

mNo edit summary |

Added Template |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:PneumaticCylinder2.jpg|300px|right]] | [[File:PneumaticCylinder2.jpg|300px|right]] | ||

__TOC__ | |||

=====Description===== | |||

[http://en.wikipedia.org/wiki/Pneumatic_cylinder '''Pneumatic cylinders'''] convert the energy in the compressed air into linear motion. The air enters the cylinder and pushes a piston from one end of the cylinder to the other. There are two main types of cylinder - '''single acting''' and '''double acting'''. A single acting cylinder has only one air connection, whilst a double acting has two. | [http://en.wikipedia.org/wiki/Pneumatic_cylinder '''Pneumatic cylinders'''] convert the energy in the compressed air into linear motion. The air enters the cylinder and pushes a piston from one end of the cylinder to the other. There are two main types of cylinder - '''single acting''' and '''double acting'''. A single acting cylinder has only one air connection, whilst a double acting has two. | ||

=====SingleActingCylinder===== | |||

[[File:PneumaticsSingleActingCylinder.jpg|600px|center]] | [[File:PneumaticsSingleActingCylinder.jpg|600px|center]] | ||

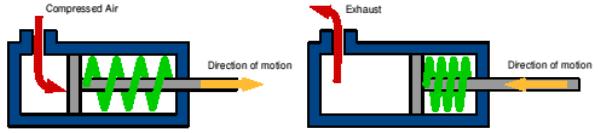

In a [http://en.wikipedia.org/wiki/Single-_and_double-acting_cylinders '''single acting cylinder'''], the piston is forced out by the pressure of the air. When the air supply is removed and the air inside the cylinder is allowed to escape, the piston moves back, driven by the force of a spring. By restricting the escaping air ''(exhaust)'', it is possible to slow down the return movement of the piston. | In a [http://en.wikipedia.org/wiki/Single-_and_double-acting_cylinders '''single acting cylinder'''], the piston is forced out by the pressure of the air. When the air supply is removed and the air inside the cylinder is allowed to escape, the piston moves back, driven by the force of a spring. By restricting the escaping air ''(exhaust)'', it is possible to slow down the return movement of the piston. | ||

[[File:3-2ValveSingleActingCylinder.gif|300px|right]] | |||

The circuit ''(schematic)'' diagram for a 3/2 valve driving a single acting cylinder is shown opposite. Note that the 3/2 valve is shown with a palm actuator and a spring return. Pushing the actuator with the palm of the hand will switch the valve on, and letting go will allow the return spring to switch the valve off. When the valve is switched on, compressed air is allowed through to the cylinder. When it is switched off, the air from the cylinder is allowed to escape to the atmosphere. | |||

<div style="clear: both;"></div> | |||

=====DoubleActingCylinder===== | |||

[[File:PneumaticsDoubleActingCylinder.jpg|600px|center]] | [[File:PneumaticsDoubleActingCylinder.jpg|600px|center]] | ||

The [http://en.wikipedia.org/wiki/Single-_and_double-acting_cylinders '''double acting cylinder'''] | The [http://en.wikipedia.org/wiki/Single-_and_double-acting_cylinders '''double acting cylinder'''] | ||

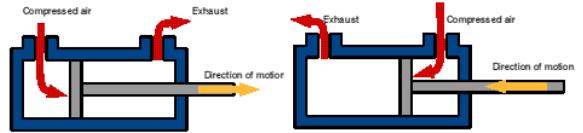

has two air connections. When compressed air is applied to one connector and the other connector is allowed to exhaust to atmosphere ''(i.e. the air is allowed to escape freely)'', the piston is driven to one end of the cylinder. When air is then applied to the second connector and the first is allowed to exhaust to atmosphere, the piston is driven back. This type of cylinder gives greater power on the return stroke than the single acting cylinder, and also ensures that the piston is effectively locked in position at both ends of its stroke. | has two air connections. When compressed air is applied to one connector and the other connector is allowed to exhaust to atmosphere ''(i.e. the air is allowed to escape freely)'', the piston is driven to one end of the cylinder. When air is then applied to the second connector and the first is allowed to exhaust to atmosphere, the piston is driven back. This type of cylinder gives greater power on the return stroke than the single acting cylinder, and also ensures that the piston is effectively locked in position at both ends of its stroke. | ||

[[File:5-2ValveDoubleActingCylinder.gif|300px|right]] | |||

The 5/2 valve is used to control items such as double acting cylinders which have two inputs. The inputs to the cylinder are connected to ports 2 and 4, the air supply to port 1. Ports 3 and 5 are allowed to exhaust to atmosphere. | |||

The number 5 signifies that the valve has five ports, whilst the number 2 signifies that the valve has 2 directions or states. | |||

<div style="clear: both;"></div> | |||

{{Pneumatic Actuators Buyers Guide}} | |||

[[Category:Secondary]] | [[Category:Secondary]] | ||

[[Category:Pneumatics]] | [[Category:Pneumatics]] | ||

Latest revision as of 17:41, 26 June 2016

Description

Pneumatic cylinders convert the energy in the compressed air into linear motion. The air enters the cylinder and pushes a piston from one end of the cylinder to the other. There are two main types of cylinder - single acting and double acting. A single acting cylinder has only one air connection, whilst a double acting has two.

SingleActingCylinder

In a single acting cylinder, the piston is forced out by the pressure of the air. When the air supply is removed and the air inside the cylinder is allowed to escape, the piston moves back, driven by the force of a spring. By restricting the escaping air (exhaust), it is possible to slow down the return movement of the piston.

The circuit (schematic) diagram for a 3/2 valve driving a single acting cylinder is shown opposite. Note that the 3/2 valve is shown with a palm actuator and a spring return. Pushing the actuator with the palm of the hand will switch the valve on, and letting go will allow the return spring to switch the valve off. When the valve is switched on, compressed air is allowed through to the cylinder. When it is switched off, the air from the cylinder is allowed to escape to the atmosphere.

DoubleActingCylinder

The double acting cylinder

has two air connections. When compressed air is applied to one connector and the other connector is allowed to exhaust to atmosphere (i.e. the air is allowed to escape freely), the piston is driven to one end of the cylinder. When air is then applied to the second connector and the first is allowed to exhaust to atmosphere, the piston is driven back. This type of cylinder gives greater power on the return stroke than the single acting cylinder, and also ensures that the piston is effectively locked in position at both ends of its stroke.

The 5/2 valve is used to control items such as double acting cylinders which have two inputs. The inputs to the cylinder are connected to ports 2 and 4, the air supply to port 1. Ports 3 and 5 are allowed to exhaust to atmosphere.

The number 5 signifies that the valve has five ports, whilst the number 2 signifies that the valve has 2 directions or states.

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |