Pneumatic Components and Symbols: Difference between revisions

From DT Online

m Added Images |

mNo edit summary |

||

| (28 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[File: | [[File:Collection of LEGO pneumatic components.jpg|500px|right|Collection of LEGO pneumatic components]] | ||

__TOC__ | |||

===Symbols=== | |||

'''Pneumatic symbols''' are used to describe the function of the various valves and other devices which are connected together to form circuits and sub circuits. | '''Pneumatic symbols''' are used to describe the function of the various valves and other devices which are connected together to form circuits and sub circuits. | ||

In the left-hand box, the arrow indicates that both ports are open and air would be allowed to pass through the valve in this position. In the right-hand box, the same two ports are shown as blocked. In this position, air is not allowed to pass. | Pneumatically controlled devices use pneumatic valves to control and direct the air and enable operations such as lifting, moving, pressing, etc. | ||

[[File:PneumaticsValveSymbols.jpg|200px|right]] | |||

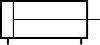

Symbols for valves are shown as boxes representing the different operating positions - the symbol shown for example is based on two boxes so it is a two position, or 2-stage, valve. Looking at any one of the boxes gives an indication of the number of ports on the valve - in this case there are 2 ports in each box ''(i.e. at centre top and bottom)'' so it would be a 2-port, 2-stage valve (2/2 Valve) - i.e. it has 2 ports and 2 operating states or positions that the valve can be in ''(i.e. Input and Output : Open or Closed)''. | |||

In the left-hand box, the arrow indicates that both ports are open and air would be allowed to pass through the valve in this position. In the right-hand box, the same two ports are shown as blocked. In this position, air is not allowed to pass. Ports are where pipe can be connected and have numbers which, if they comply with standard [http://www.iso.org/iso/catalogue_detail.htm?csnumber=33074 '''ISO 5599'''], are stamped onto the casing of the valves as follows : | |||

{| cellpadding="5" border=0 width=100% | |||

| '''Port 1 :''' | |||

'''Main Air''' | |||

| The Main Air input is supplied from a compressor or similar device and distributed through a manifold. Main air is identified by this symbol : | |||

| width=12%|[[File:PneumaticsAirSupply.jpg|50px|right]] | |||

|- | |||

| '''Port 2 :''' | |||

'''Output Connection''' | |||

| Where connections are made to other components, usually cylinders. On five-port valves, used with '''''Double-Acting Cylinders''''', it is usually connected to '''''instroke''''' and '''Port 4''' is usually connected to '''''outstroke''''' is identified by this symbol: | |||

| width=12%|[[File:PneumaticsOutletSymbol.jpg|50px|right]] | |||

|- | |||

| '''Port 3 :''' | |||

'''Exhaust''' | |||

| This port allows air trapped in the circuit to escape to atmosphere or exhaust. Also, cylinders need the air on the other side of the piston to escape. Five-port valves, for use with '''''Double-Acting Cylinders''''', have a second '''Exhaust Port 5'''. Exhaust outlets are identified by this symbol : | |||

| [[File:PneumaticsExhaustAirSymbol.jpg|50px|right]] | |||

|- | |||

| colspan=3|'''''A 3/2 valve gets its name because it has three ports and two states as follows :''''' | |||

|- | |||

| '''State 1 – off/unactuated state :''' | |||

| The main air supply through the valve is blocked and so air is unable to reach other components, such as cylinders. However, any air within the cylinder is able to exhaust through the valve and this will allow the cylinder to return to its original position. | |||

| [[File:PneumaticsValvePortsClosed.jpg|50px|right]] | |||

|- | |||

| '''State 2 – on/actuated state :''' | |||

| The main air supply is able to flow freely through the valve and supply components, such as cylinders, with air. A three-port valve symbol shows both states side by side and is usually drawn in the off or unactuated state. | |||

| [[File:PneumaticsValvePortsOpen.jpg|50px|right]] | |||

|- | |||

|} | |||

---- | ---- | ||

{| cellpadding="5" border=0 | ===Components=== | ||

=====Air Supply and Distribution===== | |||

{| cellpadding="5" border=0 width=100% | |||

|- | |- | ||

| align=left|'''Component''' | |||

| colspan=4 align=left|'''Name and Description''' | |||

| width=12%|'''Symbol''' | |||

|- | |- | ||

| [[File:PneumaticsCompressor.jpg|100px|left]] | | [[File:PneumaticsCompressor.jpg|100px|left]] | ||

| '''Compressor''' | | '''Compressor''' | ||

| colspan=3|The symbol shown is that for the Main Air Supply which is normally supplied by a compressor. | | colspan=3|The symbol shown is that for the Main Air Supply which is normally supplied by a compressor. High pressure air can be produced using piston, screw or vane [http://en.wikipedia.org/wiki/Air_compressor '''compressors''']. | ||

| [[File:PneumaticsAirSupply.jpg| | | [[File:PneumaticsAirSupply.jpg|50px|right]] | ||

|- | |- | ||

| [[File:AirReservoir.jpg|100px|left]] | | [[File:AirReservoir.jpg|100px|left]] | ||

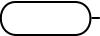

| '''Receiver''' | | '''Receiver''' | ||

| colspan=3|The air produced by the compressor is stored in a vessel called the receiver or reservoir. The function of the receiver is to store the air for future use, to smooth pressure | | colspan=3|The air produced by the compressor is stored in a vessel called the [http://en.wikipedia.org/wiki/Pressure_vessel '''receiver'''] or [http://en.wikipedia.org/wiki/Pressure_vessel '''reservoir''']. The function of the receiver is to store the air for future use, to smooth uneven pressure and to allow water to fall out of the air to the bottom of the tank where it can be drained. | ||

| [[File:PneumaticsReservoirSymbol.jpg|100px|right]] | | [[File:PneumaticsReservoirSymbol.jpg|100px|right]] | ||

|- | |||

| [[File:PneumaticsLineFilter.jpg|50px|left]] | |||

| '''Filter''' | |||

| colspan=3|Filters are used to remove small particles from the air which, if allowed to remain, would block small ports and jam spools etc. | |||

| [[File:PneumaticsLineFilterSymbol.jpg|50px|right]] | |||

|- | |||

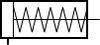

| [[File:PneumaticsRegulator.jpg|50px|left]] | |||

| '''Regulator''' | |||

| colspan=3|Compressors produce air at a higher pressure than is normally required to overcome losses in the distribution system. A pressure regulator is used to lower the pressure for the system components. A pilot signal ''(the dotted line on the right-hand side of the symbol)'' monitors the output pressure of the valve. This pilot pressure acts against a spring which is used to set the pressure. | |||

| [[File:PneumaticsRegulatorSymbol.jpg|50px|right]] | |||

|- | |||

| [[File:PneumaticsManifold.jpg |50px|left]] | |||

| '''Manifold''' | |||

| colspan=3|This enables several components to be connected to the compressed air source and provides a means of switching circuits on and off. | |||

| [[File:PneumaticsManifoldSymbol.jpg|75px|right]] | |||

|- | |||

| [[File:PneumaticsAirBleed.jpg|50px|left]] | |||

| '''Air Bleed''' | |||

| colspan=3|This is simply an open pipe that allows the air in the circuit to escape once pressure is reduced by a [http://en.wikipedia.org/wiki/Diaphragm_valve '''diaphragm valve''']. | |||

| [[File:PneumaticsAirBleedSymbol.jpg|50px|right]] | |||

|- | |- | ||

| colspan=2 rowspan=2|[[File:PneumaticsAirLines.jpg|200px|left]] | | colspan=2 rowspan=2|[[File:PneumaticsAirLines.jpg|200px|left]] | ||

| '''Air Pipes Connected''' | | width=15%|'''Air Pipes Connected''' | ||

| colspan=2|The air produced by the compressor is distributed by air lines or pipe-work to the points where it is required. | | colspan=2|The air produced by the compressor is distributed by air lines or pipe-work to the points where it is required. The lines or pipe can be connected together using 'T' pieces. | ||

| [[File:PneumaticsAirLinesConnectedSymbol.jpg |100px|right]] | | [[File:PneumaticsAirLinesConnectedSymbol.jpg |100px|right]] | ||

|- | |- | ||

| Line 31: | Line 96: | ||

| colspan=2|In a factory the pipe-work is run downhill in a further attempt to remove excess water from the system. | | colspan=2|In a factory the pipe-work is run downhill in a further attempt to remove excess water from the system. | ||

| [[File:PneumaticsAirLinesNotConnectedSymbol.jpg|100px|right]] | | [[File:PneumaticsAirLinesNotConnectedSymbol.jpg|100px|right]] | ||

|} | |||

{{Pneumatics Connections Buyers Guide}} | |||

=====Control Valves===== | |||

{| cellpadding="5" border=0 width=100% | |||

|- | |- | ||

| | | align=left|'''Component''' | ||

| colspan=4 align=left|'''Name and Description''' | |||

| | | width=12%|'''Symbol''' | ||

| | |||

|- | |- | ||

| [[File: | | [[File:2PortValve.jpg|100px|left]] | ||

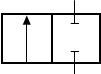

| | | '''[[Pneumatic Control Valves|3-2 Valve]]''' | ||

| | | colspan=3|This valve shows 3 ports in each box and 2 boxes to indicate it has 2 stages of operation - hence [[Pneumatic Control Valves|'''''3-2 Valve''''']]. Single-acting cylinders are normally controlled by three-port valves | ||

| [[File: | | [[File:Pneumatics3-2ValveSymbol.jpg|100px|right]] | ||

|- | |- | ||

| [[File: | | [[File:P-12-510.jpg|100px|left]] | ||

| | | '''[[Pneumatic Control Valves|5-2 Valve]]''' | ||

| | | colspan=3|This valve shows 5 ports in each box and 2 boxes to indicate it has 2 stages of operation - hence [[Pneumatic Control Valves|'''''5-2 Valve''''']]. Double-acting cylinders are normally controlled by a 5-port valve which is operated by '''''Pilot Air''''' signals from two three-port valves causing a '''''spool''''' inside the valve to move to one side or the other. | ||

| [[File: | | [[File:Pneumatics5-2ValveSymbol.jpg |100px|right]] | ||

|- | |- | ||

| [[File:## | | | ||

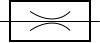

| | | '''Exhaust''' | ||

| | | colspan=3|The symbol shown is used to indicate when compressed air is released to the atmosphere - e.g. following the operation of a valve. | ||

| [[File: | | [[File:PneumaticsExhaustAirSymbol.jpg |50px|right]] | ||

-- | |- | ||

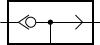

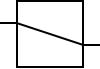

| [[File:FlowControlValve.jpg|75px|left]] | |||

| '''Unidirectional Flow Control''' | |||

| colspan=3|These control the speed of cylinder operation by restricting the flow of compressed air. This symbol shows the inclusion of a '''''restrictor''''' and a '''''check valve''''', or '''''non-return valve''''', used such that air is restricted from left to right and will free flow only from right to left. | |||

| [[File:PneumaticsUnidirectionalFlowControlSymbol.jpg|100px|right]] | |||

|- | |||

| | |||

| '''2-way Flow Control''' | |||

| colspan=3|This symbol omits the check valve to indicate that the air is able to flow in either direction | |||

| [[File:PneumaticsFlowControlValveAdjustable.jpg|100px|right]] | |||

|- | |||

| | |||

| '''Fixed Value Flow Control''' | |||

| colspan=3|This symbol omits both the check valve and the variable arrow to indicate that the air is able to flow in either direction with pressure lowered to a set value. | |||

| [[File:PneumaticsFlowControlValveFixed.jpg|100px|right]] | |||

|} | |||

{{Pneumatics Valves Buyers Guide}} | |||

=====Pneumatic Logic===== | |||

{| cellpadding="5" border=0 width=100% | |||

|- | |||

| align=left|'''Component''' | |||

| colspan=4 align=left|'''Name and Description''' | |||

| width=12%|'''Symbol''' | |||

|- | |||

| [[File:ShuttleValve.jpg|100px|left]] | |||

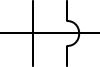

| '''Shuttle Valve''' | |||

| colspan=3|These are used with two valves in [http://en.wikipedia.org/wiki/Series_and_parallel_circuits#Series_circuits '''parallel'''] and are also known as [[Pneumatic Logic|'''‘OR’''' valves]]. They allow a signal to pass through from either input A or B ''(or both)'' and will allow the reverse flow of system exhaust through these same inputs. A shuttle valve selects the higher of two pressures by means of a small ball inside which gets blown from side to side. | |||

| [[File:PneumaticsShuttleValveSymbol.jpg|100px|right]] | |||

|- | |||

| [[File:PneumaticANDValve.jpg|100px|left]] | |||

| '''AND Valve''' | |||

| colspan=3|This valve can be used to logically decide if there is move than one signal present on the inputs. It can be used to determine if a part is in position '''‘AND’''' a guard is down before performing a clamping operation for example. The same logic [[Pneumatic Logic|'''‘AND’''' function]] can be achieved by combining two in [http://en.wikipedia.org/wiki/Series_and_parallel_circuits#Series_circuits '''series''']. | |||

| [[File:PneumaticsANDValveSymbol.jpg|100px|right]] | |||

|} | |||

{{Pneumatics Logic Control Valve Buyers Guide}} | |||

=====Actuators===== | |||

{| cellpadding="5" border=0 width=100% | |||

|- | |||

| align=left|'''Component''' | |||

| colspan=4 align=left|'''Name and Description''' | |||

| width=12%|'''Symbol''' | |||

|- | |||

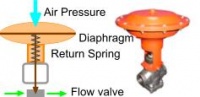

| colspan=2|[[File:PneumaticDiaphragmActivator.jpg|200px|left]] | |||

| width=12%|'''Diaphragm Actuator''' | |||

| colspan=2|These are capable of detecting small changes in air pressure. The diaphragm is a stretched piece of rubber which expands and contracts with the changing air pressure of a '''''Pilot Air''''' signal from an '''''Air Bleed''''', for example, and acts on the valve to change its state | |||

| [[File:PneumaticsDiaphragmActuatorSymbol.jpg|50px|right]] | |||

|- | |||

| | |||

| '''Pilot Air''' | |||

| colspan=3|Pilot signals can be used to operate a switch or [http://en.wikipedia.org/wiki/Actuator '''actuator'''] by monitoring the output pressure of a valve for example and supply a pressure which acts against a '''''regulator''''' spring to set the working pressure or to operate the '''''spool''''' inside a 5 port valve. | |||

| [[File:PneumaticsPilotAirSymbol.jpg|100px|right]] | |||

|- | |||

| [[File:PneumaticsSolenoidActivator.jpg |75px|left]] | |||

| '''Solenoid Actuator''' | |||

| colspan=3|Solenoids uses an electrical pulse to change the state of the valve. This allows pneumatics to be combined with electrical or electronic systems involving computer or progammable logic control [http://en.wikipedia.org/wiki/Programmable_logic_controller '''(PLC)'''] if required. | |||

| [[File:PneumaticsSolenoidActivatorSymbol.jpg|100px|right]] | |||

|- | |||

| colspan=2 rowspan=4|[[File:PneumaticManualActivators.jpg|200px|left]] | |||

| colspan=2 rowspan=4|Control valves require switching in some way and there are many ways of actuating the them. | |||

'''Solenoids''' and pilots are are switched indirectly from some other source : electrically in the case of a solenoid ''(by [https://en.wikipedia.org/wiki/Programmable_logic_controller '''PLC'''] for example)'' or by another valve in the case of a '''Pilot Air'''. | |||

Solenoids and Pilot Air are common methods of operation but valve actuation can be achieved most simply by a mechanical operation. | |||

'''Mechanical Actuators''' include push buttons, levers, rollers, and plungers. They are methods used for manual operation and shown illustrated are the actuator symbols. | |||

| width=12%|'''Push Button''' | |||

| [[File:PneumaticsPushButtonActuator.jpg|50px|right]] | |||

|- | |||

| '''Lever''' | |||

| [[File:PneumaticsLeverActuator.jpg|50px|right]] | |||

|- | |||

| width=12%|'''Roller''' | |||

| [[File:PneumaticsRollerActuator.jpg |50px|right]] | |||

|- | |||

| width=12%|'''Plunger''' | |||

| [[File:PneumaticsPlungerActuator.jpg|50px|right]] | |||

|} | |} | ||

=====Pneumatic Cylinders (or Linear Actuators)===== | |||

{| cellpadding="5" border=0 width=100% | |||

|- | |||

| align=left|'''Component''' | |||

| colspan=4 align=left|'''Name and Description''' | |||

| width=12%|'''Symbol''' | |||

|- | |||

| [[File:PneumaticsSingleActingCylinderDiagram.jpg|100px|left]] | |||

| '''Single-acting Cylinder''' | |||

| colspan=3|Pneumatic cylinders are more accurately termed '''''linear actuators'''''. In a single-acting cylinder, compressed air is used to push the piston out '''''(outstroke)''''', and a spring to return it '''''(instroke)'''''. When compressed air is supplied to the cylinder, the piston rod extends. A single-acting cylinder is normally controlled by a three-port valve. | |||

| [[File:PneumaticsSingleActingCylinderSymbol.jpg|100px|right]] | |||

|- | |||

| [[File:DoubleActingCylinder2.jpg|100px|left]] | |||

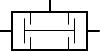

| '''Double-acting Cylinder''' | |||

| colspan=3|Double-acting cylinders use compressed air for the '''''outstroke''''' and also for the '''''instroke''''' by reversing the air flow direction which is achieved using a five-port valve. They can produce bigger forces and are used more than single-acting cylnders. They can be used for both pushing and pulling. | |||

| [[File:PneumaticsDoubleActingCylinderSymbol.jpg|100px|right]] | |||

|- | |||

|} | |||

{{Pneumatic Actuators Buyers Guide}} | |||

[[Category:Secondary]] | |||

[[Category:Pneumatics Components]] | |||

Latest revision as of 10:51, 3 January 2017

Symbols

Pneumatic symbols are used to describe the function of the various valves and other devices which are connected together to form circuits and sub circuits.

Pneumatically controlled devices use pneumatic valves to control and direct the air and enable operations such as lifting, moving, pressing, etc.

Symbols for valves are shown as boxes representing the different operating positions - the symbol shown for example is based on two boxes so it is a two position, or 2-stage, valve. Looking at any one of the boxes gives an indication of the number of ports on the valve - in this case there are 2 ports in each box (i.e. at centre top and bottom) so it would be a 2-port, 2-stage valve (2/2 Valve) - i.e. it has 2 ports and 2 operating states or positions that the valve can be in (i.e. Input and Output : Open or Closed).

In the left-hand box, the arrow indicates that both ports are open and air would be allowed to pass through the valve in this position. In the right-hand box, the same two ports are shown as blocked. In this position, air is not allowed to pass. Ports are where pipe can be connected and have numbers which, if they comply with standard ISO 5599, are stamped onto the casing of the valves as follows :

Components

Air Supply and Distribution

| Component | Name and Description | Symbol | |||

|

Compressor | The symbol shown is that for the Main Air Supply which is normally supplied by a compressor. High pressure air can be produced using piston, screw or vane compressors. | |||

|

Receiver | The air produced by the compressor is stored in a vessel called the receiver or reservoir. The function of the receiver is to store the air for future use, to smooth uneven pressure and to allow water to fall out of the air to the bottom of the tank where it can be drained. | |||

|

Filter | Filters are used to remove small particles from the air which, if allowed to remain, would block small ports and jam spools etc. | |||

|

Regulator | Compressors produce air at a higher pressure than is normally required to overcome losses in the distribution system. A pressure regulator is used to lower the pressure for the system components. A pilot signal (the dotted line on the right-hand side of the symbol) monitors the output pressure of the valve. This pilot pressure acts against a spring which is used to set the pressure. |  | ||

| Manifold | This enables several components to be connected to the compressed air source and provides a means of switching circuits on and off. | ||||

| Air Bleed | This is simply an open pipe that allows the air in the circuit to escape once pressure is reduced by a diaphragm valve. | ||||

|

Air Pipes Connected | The air produced by the compressor is distributed by air lines or pipe-work to the points where it is required. The lines or pipe can be connected together using 'T' pieces. |  | ||

| Air Pipes Not Connected | In a factory the pipe-work is run downhill in a further attempt to remove excess water from the system. |  | |||

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |

Control Valves

| Component | Name and Description | Symbol | |||

|

3-2 Valve | This valve shows 3 ports in each box and 2 boxes to indicate it has 2 stages of operation - hence 3-2 Valve. Single-acting cylinders are normally controlled by three-port valves |  | ||

|

5-2 Valve | This valve shows 5 ports in each box and 2 boxes to indicate it has 2 stages of operation - hence 5-2 Valve. Double-acting cylinders are normally controlled by a 5-port valve which is operated by Pilot Air signals from two three-port valves causing a spool inside the valve to move to one side or the other. |  | ||

| Exhaust | The symbol shown is used to indicate when compressed air is released to the atmosphere - e.g. following the operation of a valve. | ||||

|

Unidirectional Flow Control | These control the speed of cylinder operation by restricting the flow of compressed air. This symbol shows the inclusion of a restrictor and a check valve, or non-return valve, used such that air is restricted from left to right and will free flow only from right to left. |  | ||

| 2-way Flow Control | This symbol omits the check valve to indicate that the air is able to flow in either direction | ||||

| Fixed Value Flow Control | This symbol omits both the check valve and the variable arrow to indicate that the air is able to flow in either direction with pressure lowered to a set value. | ||||

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |

Pneumatic Logic

| Component | Name and Description | Symbol | |||

|

Shuttle Valve | These are used with two valves in parallel and are also known as ‘OR’ valves. They allow a signal to pass through from either input A or B (or both) and will allow the reverse flow of system exhaust through these same inputs. A shuttle valve selects the higher of two pressures by means of a small ball inside which gets blown from side to side. | |||

|

AND Valve | This valve can be used to logically decide if there is move than one signal present on the inputs. It can be used to determine if a part is in position ‘AND’ a guard is down before performing a clamping operation for example. The same logic ‘AND’ function can be achieved by combining two in series. |  | ||

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |

Actuators

| Component | Name and Description | Symbol | |||

|

Diaphragm Actuator | These are capable of detecting small changes in air pressure. The diaphragm is a stretched piece of rubber which expands and contracts with the changing air pressure of a Pilot Air signal from an Air Bleed, for example, and acts on the valve to change its state |  | ||

| Pilot Air | Pilot signals can be used to operate a switch or actuator by monitoring the output pressure of a valve for example and supply a pressure which acts against a regulator spring to set the working pressure or to operate the spool inside a 5 port valve. | ||||

|

Solenoid Actuator | Solenoids uses an electrical pulse to change the state of the valve. This allows pneumatics to be combined with electrical or electronic systems involving computer or progammable logic control (PLC) if required. |  | ||

|

Control valves require switching in some way and there are many ways of actuating the them.

Solenoids and pilots are are switched indirectly from some other source : electrically in the case of a solenoid (by PLC for example) or by another valve in the case of a Pilot Air. Solenoids and Pilot Air are common methods of operation but valve actuation can be achieved most simply by a mechanical operation. Mechanical Actuators include push buttons, levers, rollers, and plungers. They are methods used for manual operation and shown illustrated are the actuator symbols. |

Push Button | |||

| Lever | |||||

| Roller |  | ||||

| Plunger |  | ||||

Pneumatic Cylinders (or Linear Actuators)

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |