Broaches: Difference between revisions

From DT Online

mNo edit summary |

Added Template |

||

| (One intermediate revision by one other user not shown) | |||

| Line 13: | Line 13: | ||

---- | ---- | ||

{{Broaches Buyers Guide}} | |||

[[Category:Punches]] | [[Category:Punches]] | ||

Latest revision as of 12:15, 15 May 2016

Description

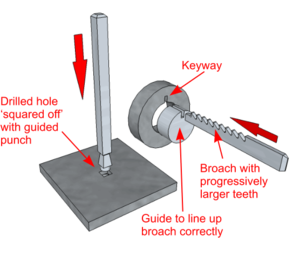

Broaches provide a means of re-shaping a previously drilled hole by pressing or striking through it a tapered cutter.

Features and Uses

Broaching is generally a machining process in which shaped cutters are pushed or drawn through pre-drilled holes to modify their shape in some way (e.g. to make them square or to cut grooves or Keyways inside a hole if used with a guide piece as shown).

Activity: Small Broaches can be hand-made by the user from Hardened and Tempered Tool Steel, as shown, and struck with a hammer to square off holes and cut Keyways.

- If a suitable section of Tool Steel is not available, Broaches for the small-scale work most common in Design and Technology (in Brass for example), can be made by grinding teeth profiles into the shortened length of an old file for example (ideally, first Anneal the old file and re-shape it then re-harden and temper to ensure the finished Broach is not too Brittle).

Safety Point! If making from an old file, use a short length, grind a chamfer around the striking end, apply only light taps to reduce the risk of pieces breaking off, and always wear eye protection.

|

|

| Tool Steel Round Rod |

Tool Steel Square Bar |