Materials Preparation Store Example 3: Difference between revisions

From DT Online

m Added Note |

Added text and images |

||

| Line 12: | Line 12: | ||

[[File:MaterialsPrep3.png|800px|center]] | [[File:MaterialsPrep3.png|800px|center]] | ||

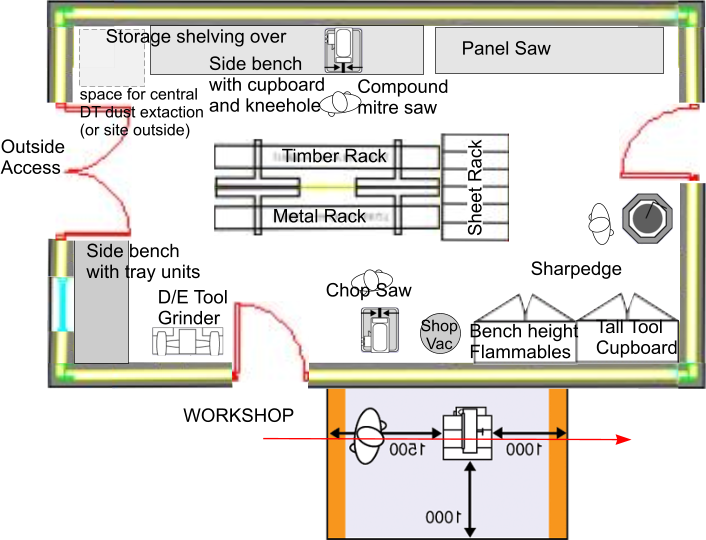

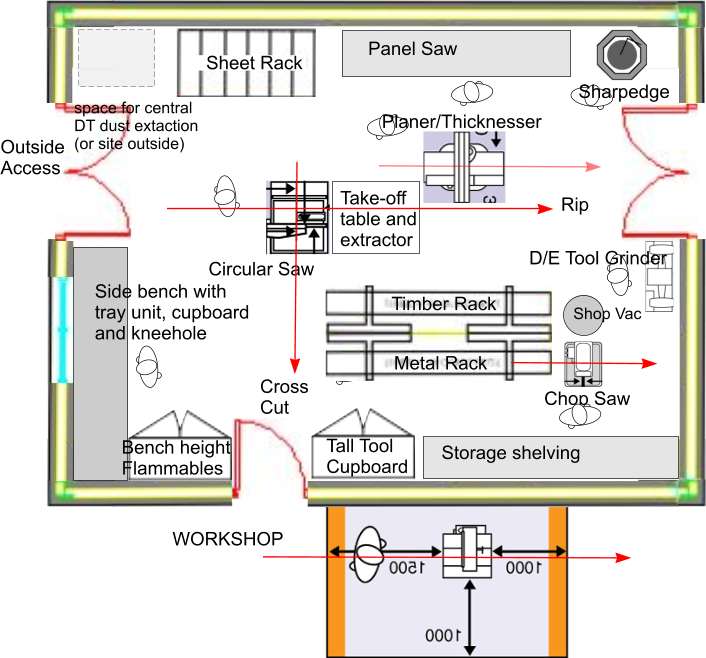

DT workshop technician based here. | |||

* Try to place in centre of workshop area, on ground floor and with outside access for deliveries | |||

* Try to ensure easy access to workshops - especially Construction and Engineering - i.e. Vocational areas | |||

* Try to position CAM area adjacent to workshop technician base and any central DT project area | |||

---- | |||

<span style="color: green">'''Note:''' | |||

The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them. | |||

</span> | |||

---- | |||

[[File:MaterialsPrep2.png|800px|center]] | |||

{| | |||

|- | |||

! Description | |||

! Code | |||

! Notes | |||

! Image | |||

|- | |||

| '''Tall Toolcupboard''' | |||

| LFSPF84 | |||

| used to store technician tools, maintenance equipment plus spares and equipment for staff use only | |||

| <dtamazon product="B00B191UB2" type="image">Flatpacked Workshop Cupboard</dtamazon> | |||

|- | |||

| '''Timber Rack''' | |||

| FFSTR449 | |||

| will go down to floor - could be back to back to create an island rack | |||

| <dtamazon product="B002QRYFCY" type="image">Triton WRA001 Woodrack Storage System </dtamazon> | |||

|- | |||

| '''Sheet Rack''' | |||

| FFSTR323 | |||

| store sheets vertically - max. sheet size 8' x 4' - self-standing island versions also available | |||

| [[File:SheetRack.png|100px|right]] | |||

|- | |||

| '''Planer/Thicknesser''' | |||

| FESEQ631 | |||

| can be positioned alongside circular saw - v. high risk machine - certificated staff use only | |||

| <dtamazon product="B004QX2IB6" type="image">Draper 36312 1600W 230V Planer Thicknesser </dtamazon> | |||

|- | |||

| '''Circular Saw''' | |||

| LESEQ297 | |||

| position in line with doors as shown where possible for both ripping and cross-cutting - v. high risk machine - certificated staff use only | |||

| <dtamazon product="B00JE2MLG6" type="image">Charnwood W619 Cast Iron Table Saw C/W Sliding Carriage & Extension Tables 24V0 </dtamazon> | |||

|- | |||

| '''Take-off Table''' | |||

| FESEQ629 | |||

| essential for circular saws to have - versions available which house dust extraction under | |||

| [[File:DustExtraction.png|100px|right]] | |||

|- | |||

| '''Compound Mitre Saw''' | |||

| FESEQ### | |||

| fix to bench for cross-cutting and jointing | |||

| <dtamazon product="B0013UY7N2" type="image">Makita MLS100 240 V 255 mm Electric Saw</dtamazon> | |||

|- | |||

| '''Panel Saw''' | |||

| FESEQ### | |||

| either wall-mounted or folding stand available | |||

| <dtamazon product="B00IEHMYRS" type="image">Cutting-Edge Safety Speed Cut C4 Panel Saw & NV750 Workshop Vacuum Extractor - (CLEVA VALUE BUNDLE) - [Pike & Co.® Branded] w/Min 3yr Warranty</dtamazon> | |||

|- | |||

| '''Side Bench''' | |||

| FFFFU47 | |||

| for technician use - try to position near window | |||

| <dtamazon product="B003XCW9XS" type="image">NEW CWB-R1 CLARKE BALL BEARING WORKSHOP/CAR WORKBENCH</dtamazon> | |||

|- | |||

| '''Underbench Tray Unit''' | |||

| FFSTR67 | |||

| ### | |||

| <dtamazon product="B0071LT3X6" type="image">GratStack wide storage unit with 18 plastic Gratnells trays</dtamazon> | |||

|- | |||

| '''Tool Sharpener''' | |||

| FESEQ532 | |||

| used for grinding wood chisels and plane irons for example - both floor and bench mounted machines available | |||

| | <dtamazon product="B0026LVYYC" type="image">Tormek T-7 Water Cooled Precision Sharpening System, 10 Inch Stone</dtamazon> | |||

|- | |||

| '''D/E Tool Grinder''' | |||

| FESEQ600 | |||

| used to sharpen lathe tools for example - both floor and bench mounted machines available | |||

| <dtamazon product="B0001K9S2K" type="image">Draper 29620 150 mm 230-Volt 370-Watt 3,000 rpm Heavy-Duty Bench Grinder </dtamazon> | |||

|- | |||

| '''Flammables Cupboard''' | |||

| LFSTR70 | |||

| metal cabinet safely to store solvents and other flammable liquids - a range of sizes available. | |||

| <dtamazon product="B00VXUUHEU" type="image">Flammable Liquid Storage Cabinet - 710 x 915 x 457mm (HxWxD) </dtamazon> | |||

|- | |||

| '''Chop Saw''' | |||

| LESEQ337 | |||

| position near metal racks - bench mounted or fixed on floor stand | |||

| | <dtamazon product="B001ACM2GM" type="image">Dewalt D28715 240V 2200W 355mm High Performance Chopsaw </dtamazon> | |||

|- | |||

| '''Shop Vac''' | |||

| LESEQ313 | |||

| Dust extractor - need also to allow possible space for DT central dust extract system - could be located outside | |||

| | <dtamazon product="B00V3WFH16" type="image">4YourHome Commercial Wet and Dry Tub Industrial Hoover Vacuum Cleaner, 80 Litre, 2000 W, Stainless Steel/Teal [Energy Class C]</dtamazon> | |||

|- | |||

| '''Bandsaw''' | |||

| FESEQ339 | |||

| position outside storeroom door as shown where possible to enable staff use without leaving workshop - medium risk machine | |||

| <dtamazon product="B005C9AET6" type="image">Charnwood W730 14'' Woodworking Bandsaw</dtamazon> | |||

|- | |||

| '''Storage shelving''' | |||

| LFSTR234 | |||

| include shelving unit also if space is available | |||

| <dtamazon product="B00U0GLBP2" type="image">3 x Racking Bays 90cm x 180cm x 45cm 5 TIER SHELVING BAYS STORAGE SHELF UNIT WAREHOUSE GARAGE HEAVY DUTY BOLTLESS STEEL RACKING FREE MALLET</dtamazon> | |||

[[Category:Accommodating Design and Technology in Secondary Schools]] | [[Category:Accommodating Design and Technology in Secondary Schools]] | ||

Latest revision as of 18:40, 19 February 2017

DT workshop technician based here.

- Try to place in centre of workshop area, on ground floor and with outside access for deliveries

- Try to ensure easy access to workshops - especially Construction and Engineering - i.e. Vocational areas

- Try to position CAM area adjacent to workshop technician base and any central DT project area

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.

DT workshop technician based here.

- Try to place in centre of workshop area, on ground floor and with outside access for deliveries

- Try to ensure easy access to workshops - especially Construction and Engineering - i.e. Vocational areas

- Try to position CAM area adjacent to workshop technician base and any central DT project area

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.

![Cutting-Edge Safety Speed Cut C4 Panel Saw & NV750 Workshop Vacuum Extractor - (CLEVA VALUE BUNDLE) - [Pike & Co.® Branded] w/Min 3yr Warranty Cutting-Edge Safety Speed Cut C4 Panel Saw & NV750 Workshop Vacuum Extractor - (CLEVA VALUE BUNDLE) - [Pike & Co.® Branded] w/Min 3yr Warranty](http://ws-eu.amazon-adsystem.com/widgets/q?_encoding=UTF8&ASIN=B00IEHMYRS&Format=_SL110_&ID=AsinImage&MarketPlace=GB&ServiceVersion=20070822&WS=1&tag=)

![4YourHome Commercial Wet and Dry Tub Industrial Hoover Vacuum Cleaner, 80 Litre, 2000 W, Stainless Steel/Teal [Energy Class C] 4YourHome Commercial Wet and Dry Tub Industrial Hoover Vacuum Cleaner, 80 Litre, 2000 W, Stainless Steel/Teal [Energy Class C]](http://ws-eu.amazon-adsystem.com/widgets/q?_encoding=UTF8&ASIN=B00V3WFH16&Format=_SL110_&ID=AsinImage&MarketPlace=GB&ServiceVersion=20070822&WS=1&tag=)