Cold Moulding: Difference between revisions

From DT Online

mNo edit summary |

m Added Link |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:Isokon reclining chair, designed by Marcel Breuer, Isokon Furniture Company, London, 1935, bent laminated wood and plywood - Museum für Angewandte Kunst Köln - Cologne, Germany - DSC09562.jpg|400px|right|Isokon reclining chair, designed by Marcel Breuer, Isokon Furniture Company, London, 1935, bent laminated wood and plywood - Museum für Angewandte Kunst Köln - Cologne, Germany - DSC09562]] | |||

__TOC__ | |||

[ | |||

Historically, if curved shapes were required in wood, suitably shaped trees and branches would be found in the local forest and split ''(or [https://en.wikipedia.org/wiki/Cleaving_axe cleaved])'' down the centre. More commonly, curved shapes can be cut from the solid, '''[[Steam Bending|Steam Bent]]''' or '''Cold Moulded''' by '''[[Laminating]]''' together thin strips or veneers and gluing them under pressure around a former as described below. | |||

---- | |||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

Simply cutting a curved shape out of a plank of wood may result in places where the wood grain is oriented more across the width than along the length of the piece. This is known as '''Short Grain''' and is a weakness which is likely to break under load. | Simply cutting a curved shape out of a plank of wood may result in places where the wood grain is oriented more across the width than along the length of the piece. This is known as '''[[Short Grain]]''' and is a weakness which is likely to break under load. | ||

</span> | </span> | ||

---- | |||

=====Introduction===== | |||

At its simplest, to produce a curved rail for example, a mould is made in two parts as shown, then strips of timber glued and placed between them ''(note that the outer curve is larger than the inner curve to allow for the rail thickness)''. The strips should be about 1mm thick and made longer than required for the finished rail. This is because the strips will slide over each other when compressed leaving stepped ends which will need to be trimmed. | At its simplest, to produce a curved rail for example, a mould is made in two parts as shown, then strips of timber glued and placed between them ''(note that the outer curve is larger than the inner curve to allow for the rail thickness)''. The strips should be about 1mm thick and made longer than required for the finished rail. This is because the strips will slide over each other when compressed leaving stepped ends which will need to be trimmed. | ||

[[File:Laminating.png|500px|centre|Laminating a curved rail]] | |||

| Line 14: | Line 23: | ||

=====Vacuum Bag Moulding===== | |||

An alternative technique, particularly suitable for wider and shallower shapes ''(e.g. a box lid or shallow tray)'', is to use atmospheric pressure to force thin veneers around a single piece mould. The layers of veneer are glued and placed over a mould as shown. The mould should be sturdy and may be supported on a base, or [https://en.wikipedia.org/wiki/Platen platen], with slots or holes to ensure air can be drawn out. Once so prepared, the loaded mould is placed inside a sealed bag and air is sucked out to create a vacuum, causing the veneers to be pressed around the mould. The process is useful also when veneering flat sheets of '''[[Manufactured Board]]'''. | An alternative technique, particularly suitable for wider and shallower shapes ''(e.g. a box lid or shallow tray)'', is to use atmospheric pressure to force thin veneers around a single piece mould. The layers of veneer are glued and placed over a mould as shown. The mould should be sturdy and may be supported on a base, or [https://en.wikipedia.org/wiki/Platen platen], with slots or holes to ensure air can be drawn out. Once so prepared, the loaded mould is placed inside a sealed bag and air is sucked out to create a vacuum, causing the veneers to be pressed around the mould. The process is useful also when veneering flat sheets of '''[[Manufactured Board]]'''. | ||

| Line 23: | Line 31: | ||

For normal work, a strong rubber-coated fabric or polyurethane 'bag', or sealed tube, is commercially available and supplied complete with vacuum pump ''(e.g. [http://www.bagpress.com/Home.html '''Bagpress'''])''. The process can be modelled for smaller scale '''[[Design and Technology]]''' projects in thin veneers or even layers of card for example | For normal work, a strong rubber-coated fabric or polyurethane 'bag', or sealed tube, is commercially available and supplied complete with vacuum pump ''(e.g. [http://www.bagpress.com/Home.html '''Bagpress'''])''. The process can be modelled for smaller scale '''[[Design and Technology]]''' projects in thin veneers ''(or even layers of card for example)'' and simple shapes can be achieved using thick polyethylene bag evacuated with a domestic vacuum cleaner ''(some ingenuity may be required to connect the cleaner to the bag and a valve to seal the vacuum may be needed)''. | ||

[https://en.wikipedia.org/wiki/Composite_material#Vacuum_bag_moulding '''Vacuum Bag Moulding'''] ''(aka Vacuum Bagging)'' is also an alternative method of moulding fibreglass to '''Hand Lay-up'''. It has the advantage of providing even pressure over the entire mould until the resin is cured. The technique can be used also to mould relatvely shallow forms made perhaps from a lattice or layers of '''[[Steam Bending|Steam Bent]]''' thin timber srtrips or veneer. | |||

=====Use in Boat Building===== | |||

A '''Cold Moulding''' technique has been used in [https://en.wikipedia.org/wiki/Boat_building#Wood '''Boat Building'''] whereby layers of veneer are '''Laminated''' over each other with grain directions alternating at about 60-70 degrees to each other. The result is a strong monocoque structure, similar to a fibreglass hull but substantially lighter. | A '''Cold Moulding''' technique has been used in [https://en.wikipedia.org/wiki/Boat_building#Wood '''Boat Building'''] whereby layers of veneer are '''Laminated''' over each other with grain directions alternating at about 60-70 degrees to each other. The result is a strong monocoque structure, similar to a fibreglass hull but substantially lighter. | ||

[[Category: Skills and Processes]] | [[Category: Skills and Processes]] | ||

Latest revision as of 20:00, 24 December 2017

Historically, if curved shapes were required in wood, suitably shaped trees and branches would be found in the local forest and split (or cleaved) down the centre. More commonly, curved shapes can be cut from the solid, Steam Bent or Cold Moulded by Laminating together thin strips or veneers and gluing them under pressure around a former as described below.

Note: Simply cutting a curved shape out of a plank of wood may result in places where the wood grain is oriented more across the width than along the length of the piece. This is known as Short Grain and is a weakness which is likely to break under load.

Introduction

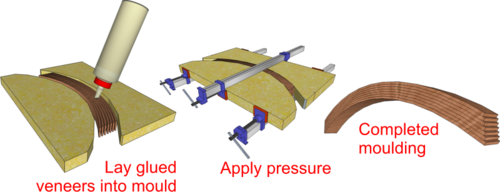

At its simplest, to produce a curved rail for example, a mould is made in two parts as shown, then strips of timber glued and placed between them (note that the outer curve is larger than the inner curve to allow for the rail thickness). The strips should be about 1mm thick and made longer than required for the finished rail. This is because the strips will slide over each other when compressed leaving stepped ends which will need to be trimmed.

The mould pieces should be waxed or covered with polyethylene for example, to prevent the Laminated rail sticking to it. The two halves are cramped together until the glue sets (e.g. using 'G' Cramps, Sash Cramps or placing in a Wood Vice for example). Once glued, the strips are unable to slide back into their original position and so the shape is retained.

Vacuum Bag Moulding

An alternative technique, particularly suitable for wider and shallower shapes (e.g. a box lid or shallow tray), is to use atmospheric pressure to force thin veneers around a single piece mould. The layers of veneer are glued and placed over a mould as shown. The mould should be sturdy and may be supported on a base, or platen, with slots or holes to ensure air can be drawn out. Once so prepared, the loaded mould is placed inside a sealed bag and air is sucked out to create a vacuum, causing the veneers to be pressed around the mould. The process is useful also when veneering flat sheets of Manufactured Board.

For normal work, a strong rubber-coated fabric or polyurethane 'bag', or sealed tube, is commercially available and supplied complete with vacuum pump (e.g. Bagpress). The process can be modelled for smaller scale Design and Technology projects in thin veneers (or even layers of card for example) and simple shapes can be achieved using thick polyethylene bag evacuated with a domestic vacuum cleaner (some ingenuity may be required to connect the cleaner to the bag and a valve to seal the vacuum may be needed).

Vacuum Bag Moulding (aka Vacuum Bagging) is also an alternative method of moulding fibreglass to Hand Lay-up. It has the advantage of providing even pressure over the entire mould until the resin is cured. The technique can be used also to mould relatvely shallow forms made perhaps from a lattice or layers of Steam Bent thin timber srtrips or veneer.

Use in Boat Building

A Cold Moulding technique has been used in Boat Building whereby layers of veneer are Laminated over each other with grain directions alternating at about 60-70 degrees to each other. The result is a strong monocoque structure, similar to a fibreglass hull but substantially lighter.