Pin Punches: Difference between revisions

From DT Online

Created article |

Created article |

||

| Line 6: | Line 6: | ||

=====Uses===== | =====Uses===== | ||

Usually parallel but available also slightly tapered as a [https://en.wikipedia.org/wiki/Drift_pin '''Drift Pin'''] to align holes together or as a specialised [https://en.wikipedia.org/wiki/Punch_(tool)#Spring_or_roll_pins '''Roll Pin Punch'''] designed to remove '''[[Pins and Clips|Roll Pins]]''' without damaging them. | |||

=====<div class="buyers-guide">DT Online Buyers' Guide</div>===== | =====<div class="buyers-guide">DT Online Buyers' Guide</div>===== | ||

* | * Choose good quality hardened and tempered steel punches to minimise the chance of their bending when struck unless there is a danger from sparks or a risk of damage to the surrounding material. | ||

* Hollow '''[[Roll Pin|Roll Pins]]''' cannot easily be punched out without damage unless a specialised '''Roll Pin Pinch''' ''(aka '''Spring Pin Punch''')'' is used. | |||

{| | {| | ||

|- | |- | ||

Revision as of 10:57, 14 May 2016

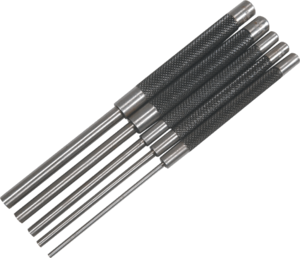

Description

Pin Punches are also known as Drifts and are used to punch pins out of holes.

Uses

Usually parallel but available also slightly tapered as a Drift Pin to align holes together or as a specialised Roll Pin Punch designed to remove Roll Pins without damaging them.

DT Online Buyers' Guide

- Choose good quality hardened and tempered steel punches to minimise the chance of their bending when struck unless there is a danger from sparks or a risk of damage to the surrounding material.

- Hollow Roll Pins cannot easily be punched out without damage unless a specialised Roll Pin Pinch (aka Spring Pin Punch) is used.