Thermoforming Plastics: Difference between revisions

From DT Online

m Added thermoforming processes |

Added text |

||

| Line 24: | Line 24: | ||

=====Press Moulding===== | =====Press Moulding===== | ||

The sheet of Acrylic can be heated in an oven a between 275°F to 350°F ''(135<sup><small>0</small></sup>C to 175<sup><small>0</small></sup>C)'' then placed over a mould shape and pressed into it as shown - the two parts of the mould should be made with an allowance between them to accommodate the thickness of plastics sheet used. | |||

Moulding plates can be '''[[Laminating|Laminated]]''' with ‘Formica’ or similar and have well rounded corners to ensure the surface finish of the Acrylic is not unduly marked as pressure is applied. | |||

Small pieces can be heated by careful use of a '''Hot Air Gun''' which is continuously moved over the surface until the Acrylic becomes suitably '''[[Malleability|Malleable]]'''. | |||

| Line 30: | Line 37: | ||

=====Drape Moulding===== | =====Drape Moulding===== | ||

The sheet of Acrylic can be heated in an oven as above or small pieces heated with a '''Hot Air Gun'''. | |||

Use oven gloves or similar when handling the hot Acrylic sheet and simply ‘drape’ it over a pre-prepared mould. | |||

Minor adjustments can be made throughout using a '''Hot Air Gun''' to maintain moulding temperature and an extended moulding time can be achieved if the mould is first pre-heated. | |||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

=====Blow Moulding===== | =====Blow Moulding===== | ||

[[File:BlowMoulder.png|750px|center]] | |||

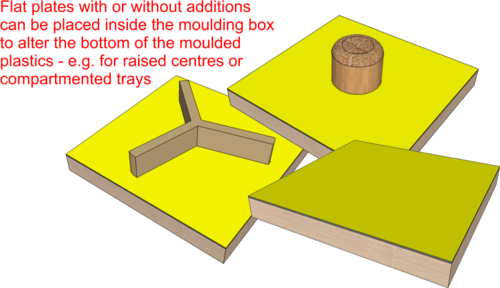

[[File:BlowMoulderBases.png |500px|left]] | |||

[[File: | |||

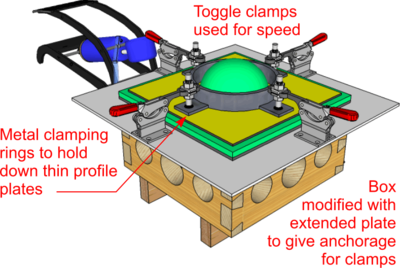

[[File:BlowMouldingRing.png |400px|right]] | |||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

=====Line Bending===== | =====Line Bending===== | ||

[[File:StripHeater.png|600px|center]] | |||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

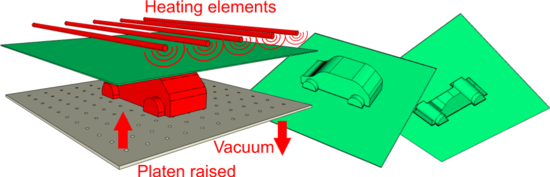

[[File:VacForming.png| | [[File:VacForming.png|550px|right]] | ||

=====Vacuum Forming===== | =====Vacuum Forming===== | ||

Revision as of 23:10, 9 November 2016

[[File:]]

Description

The term Thermoforming could be taken literally to include any process which uses heat to create a 3D form - Blacksmithing for example. Throughout DT Online the term is used to include all those processes which employ heat to mould certain plastics.

Synthetic* Plastics are chemically produced from oil and a wide, possibly infinite, variety is possible, but they all fit into one of two groupings:

- Thermoplastics - these can repeatedly be softened by heating and will return to a rigid state when cooled.

- this group includes: Acrylic, Polycarbonate (PC), Polyethylene, and Polypropylene.

- Thermosets - these are initially ‘cured’ (or set), often by mixing with a ‘hardener’ which creates a heat producing (Exothermic) chemical reaction and, once set cannot be softened again by further heating.

- this group includes: Polyester Resin, Epoxy Resin, Bakelite and Melamine.

*Note: Several natural materials may also be classified as Plastics. These include: Cellulose, Horn, Amber, and Shellac.

DT Online includes as Thermoforming all processes in which Thermoplastics are heated to create products with a particular emphasis on methods of moulding flat sheet materials.

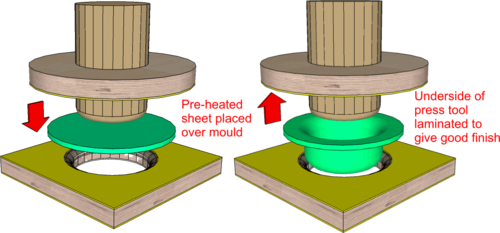

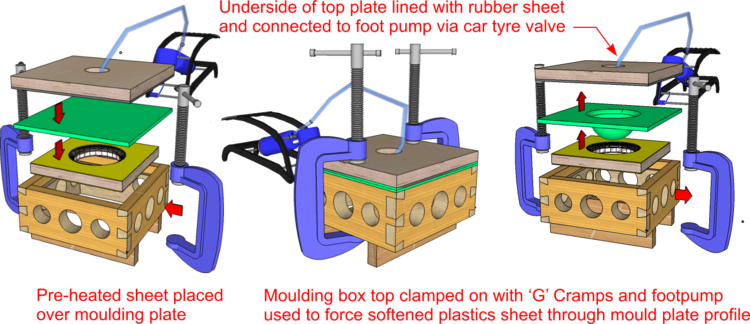

Press Moulding

The sheet of Acrylic can be heated in an oven a between 275°F to 350°F (1350C to 1750C) then placed over a mould shape and pressed into it as shown - the two parts of the mould should be made with an allowance between them to accommodate the thickness of plastics sheet used.

Moulding plates can be Laminated with ‘Formica’ or similar and have well rounded corners to ensure the surface finish of the Acrylic is not unduly marked as pressure is applied.

Small pieces can be heated by careful use of a Hot Air Gun which is continuously moved over the surface until the Acrylic becomes suitably Malleable.

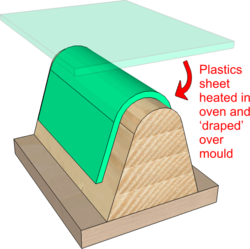

Drape Moulding

The sheet of Acrylic can be heated in an oven as above or small pieces heated with a Hot Air Gun.

Use oven gloves or similar when handling the hot Acrylic sheet and simply ‘drape’ it over a pre-prepared mould.

Minor adjustments can be made throughout using a Hot Air Gun to maintain moulding temperature and an extended moulding time can be achieved if the mould is first pre-heated.

Blow Moulding

Line Bending