Riveting: Difference between revisions

From DT Online

Created article |

Added Pop Rivetting |

||

| Line 7: | Line 7: | ||

=====Rivetting Process===== | =====Solid Rivetting Process===== | ||

# '''Rivets''' are first passed through the punched or drilled holes then, with head supported on a hard surface, a hollow tool with a hole equal to the '''Rivet''' diameter is struck down over it to squeeze, or '''Set''', the pieces of material together | # '''Rivets''' are first passed through the punched or drilled holes then, with head supported on a hard surface, a hollow tool with a hole equal to the '''Rivet''' diameter is struck down over it to squeeze, or '''Set''', the pieces of material together | ||

| Line 13: | Line 13: | ||

# The the head is formed by hammering over. | # The the head is formed by hammering over. | ||

# The completed rivetted joint. | # The completed rivetted joint. | ||

====='Pop' Rivetting===== | |||

[[File:PopRivetting.png|400px|right]] | |||

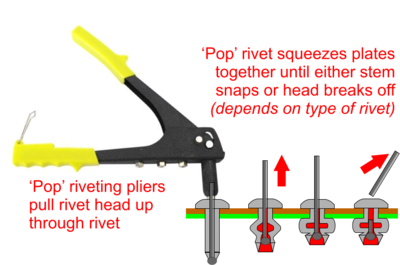

Known also as [https://en.wikipedia.org/wiki/Rivet#Blind_rivets '''Bling Rivets'''] provide a means of joining materials working from one side only ''(i.e. ‘blind)''’. This makes ''''Pop' Rivetting''' extremely useful for joining tubes and other hollow structures. | |||

* The [https://en.wikipedia.org/wiki/Mandrel '''Mandrel'''] running through the centre of the hollow rivet is gripped by either ''''Pop' Rivetting Pliers''' or '''Tongs''' and inserted into the pre-drlled hole of the workpiece. | |||

* As the pliers or tongs are squeezed, the head of the [https://en.wikipedia.org/wiki/Mandrel '''Mandrel'''] is pulled up through the rivet, which swells the ‘blind’ side of the rivet and causes the plates to be squeezed together. | |||

* Once a pre-determined '''[[Tension]]''' is reached the stem of the [https://en.wikipedia.org/wiki/Mandrel '''Mandrel'''] snaps leaving the head locked into the ‘blind’ side of the rivet . | |||

[[File:PopRivettingAcrylic.png|175px|right]] | |||

Some plastics, such as '''Acrylic''' are very '''[[Brittleness|Brittle]]''' and would normally shatter as the thickening [https://en.wikipedia.org/wiki/Rivet#Blind_rivets ''''Pop' Rivet'''] exerts '''[[Tension|Tensile]]''' forces on the inside of the hole. | |||

To avoid this, holes for ''''Pop' Rivetting''' plastics are drilled over-size and '''Backing Washers''' or plates of some kind are added such that the two pieces of plastics are exposed only to '''[[Compression|Compressive]]''' forces as they are squeezed together. | |||

This technique was used to construct canopies of [https://en.wikipedia.org/wiki/Supermarine_Spitfire '''Spitfires'''] for example where ‘Perspex’ pieces were joined together by ''''Pop' Rivetting''' aluminium strips either side. | |||

---- | ---- | ||

<span style="color: green">'''Note:''' | <span style="color: green">'''Note:''' | ||

| Line 21: | Line 40: | ||

{{Solid Rivets Buyers Guide}} | {{Solid Rivets Buyers Guide}} | ||

{{Specialised Rivets Buyers Guide}} | |||

[[Category:Skills and Processes]] | [[Category:Skills and Processes]] | ||

Revision as of 18:44, 15 November 2016

Description

Rivets (aka Rivits) have various designs of head at one end and are used to fasten materials together by being passed through a punched or drilled hole and hammered over (usually) to form a head on the reverse side. They are available in several materials and sizes, can be solid or hollow and specialised designs also exist (e.g. ‘Pop’ Rivets).

Solid Rivetting Process

- Rivets are first passed through the punched or drilled holes then, with head supported on a hard surface, a hollow tool with a hole equal to the Rivet diameter is struck down over it to squeeze, or Set, the pieces of material together

- The tool, or Rivet Set, is removed and using a hammer, the Rivet is first struck square on to thicken it inside the holes

- The the head is formed by hammering over.

- The completed rivetted joint.

'Pop' Rivetting

Known also as Bling Rivets provide a means of joining materials working from one side only (i.e. ‘blind)’. This makes 'Pop' Rivetting extremely useful for joining tubes and other hollow structures.

- The Mandrel running through the centre of the hollow rivet is gripped by either 'Pop' Rivetting Pliers or Tongs and inserted into the pre-drlled hole of the workpiece.

- As the pliers or tongs are squeezed, the head of the Mandrel is pulled up through the rivet, which swells the ‘blind’ side of the rivet and causes the plates to be squeezed together.

- Once a pre-determined Tension is reached the stem of the Mandrel snaps leaving the head locked into the ‘blind’ side of the rivet .

Some plastics, such as Acrylic are very Brittle and would normally shatter as the thickening 'Pop' Rivet exerts Tensile forces on the inside of the hole.

To avoid this, holes for 'Pop' Rivetting plastics are drilled over-size and Backing Washers or plates of some kind are added such that the two pieces of plastics are exposed only to Compressive forces as they are squeezed together.

This technique was used to construct canopies of Spitfires for example where ‘Perspex’ pieces were joined together by 'Pop' Rivetting aluminium strips either side.

Note: Where several Rivets are to be used to form a joint, it is important to drill through both parts just once initally, and this hole rivetted before drilling through and rivetting any further holes. This is because it is most unlikely that drilling separately would position the holes accurately enough.