Engineering Workshop Example 1: Difference between revisions

From DT Online

Added Product |

mNo edit summary |

||

| Line 49: | Line 49: | ||

|- | |- | ||

| '''Metal Turning Lathe''' | | '''Metal Turning Lathe''' | ||

| | | FESEQ633 | ||

| bolt securely to the floor. | | bolt securely to the floor. | ||

| <dtamazon product="B005OJ9HSS" type="image">Draper 33893 250W 230V Variable Speed Metalworking Lathe </dtamazon> | | <dtamazon product="B005OJ9HSS" type="image">Draper 33893 250W 230V Variable Speed Metalworking Lathe </dtamazon> | ||

|- | |- | ||

| '''Milling Machine''' | | '''Milling Machine''' | ||

| | | FESEQ308 | ||

| bolt securely to the floor - can be angled across an internal corner if | | bolt securely to the floor - can be angled across an internal corner if necessary - universal miller most flexible - a CNC miller is an alternative | ||

| [[File:VerticalMillingMachine.jpg|100px|right]] | | [[File:VerticalMillingMachine.jpg|100px|right]] | ||

|- | |- | ||

| Line 94: | Line 94: | ||

|- | |- | ||

| '''Surface Plate''' | | '''Surface Plate''' | ||

| | | LESEQ638 | ||

| an accurately ground datum surface from which precision marking out can be undertaken | | an accurately ground datum surface from which precision marking out can be undertaken - provide with protective cover | ||

| <dtamazon product="B00IEHMI1U" type="image">Cutting-Edge Cast Iron Surface Plate - [Pike & Co.® Branded] w/Min 3yr Warranty </dtamazon> | | <dtamazon product="B00IEHMI1U" type="image">Cutting-Edge Cast Iron Surface Plate - [Pike & Co.® Branded] w/Min 3yr Warranty </dtamazon> | ||

|- | |- | ||

| '''Bench Grinder''' | | '''Bench Grinder''' | ||

| | | FESEQ300 | ||

| for general shaping and sharpening | | for general shaping and sharpening | ||

| <dtamazon product="B005A57BAC" type="image">Draper 05096 150mm 370W 230V Bench Grinder with Sanding Belt and Worklight </dtamazon> | | <dtamazon product="B005A57BAC" type="image">Draper 05096 150mm 370W 230V Bench Grinder with Sanding Belt and Worklight </dtamazon> | ||

Revision as of 17:46, 20 February 2017

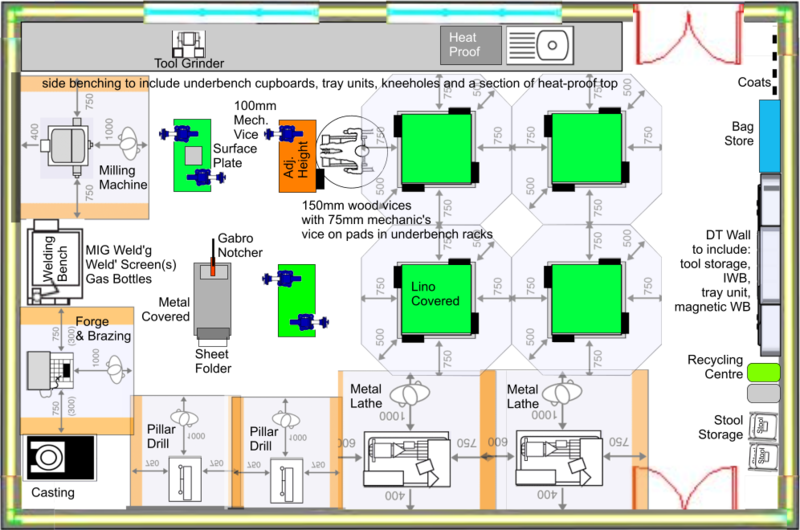

This workshop is intended particularly for examination level and vocational courses which focus on the use of metal to make functional products - it may also be use by younger pupils for general D&T work if timetable constraints dictate.

There will most often be a storeroom adjacent plus doors into the workshop and a door to the outside.

The workshop may also have access to a shared Heat Area, shared machining area and/or a collaborative project space - this is unlikey to alter the equipment inside the room but may increase the use of mobile equipment on braked trolleys brought in temporarily from outside

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.

| Description | Code | Notes | Image |

|---|---|---|---|

| Technology Bench | LFTAB20 | 1200mm x 1200mm and also 1000mm x 1000mm sizes available with optional vice rack and/or cupboard - LFSPF33 is an alternative. One bench shown split to make half adjustable height with two vices. |  |

| Bag Store | LFSTR62 | almost always needed in a practical room to avoid danger of bags on floor. |  |

| DT Storage Wall | FFFFU60 | Fitted out to take small tools etc. and includes IWB tray unit, magnetic WB, plus pull-out fully serviced teacher caddy/desk. Position 90deg to windows. |  |

| Waste Bin | LEOTR487 | in workshops needed for: paper, metal, wood, plastics, glass, plus non-recycle. |  |

| Pillar Drill | FESEQ301 | position near centre of wall to avoid crowding - MUST be bolted down - head can be height adjusted to accommodate wheelchair users - esp. if 2 machines |  |

| Metal Turning Lathe | FESEQ633 | bolt securely to the floor. |  |

| Milling Machine | FESEQ308 | bolt securely to the floor - can be angled across an internal corner if necessary - universal miller most flexible - a CNC miller is an alternative |  |

| Crucible Furnace | FESEQ316 | position near other heat equipment to share fume extraction - no other work takes place in the area during a 'pour' so can be in corner and safety spaces can overlap |  |

| Combination Forge/Brazing Hearth | FESEQ315 | position such that fume extraction system can vent to outside wall |  |

| Welding Bench | FESPF318 | provide both gas and electric welding and ensure fume extraction |  |

| Welding Screen | LESEQ637 | portable and must be provided in open workshops to protect eyes if electric welding is available |  |

| MIG Welding | LESEQ329 | for general purpose welding - provide also small portable oxy-acetylene gas welding set (e.g. for brazing, localised heating and welding thin sheet) |  |

| Sheet Folder | LESEQ636 | fix to substantial bench - also available on floor stand or could be fixed to side bench - an alternative is a Box Folder |

|

| Notcher | LESEQ340 | fix to substantial bench - also available on floor stand and larger version - alternatively use ordinary Bench Shears |  |

| Surface Plate | LESEQ638 | an accurately ground datum surface from which precision marking out can be undertaken - provide with protective cover | ![Cutting-Edge Cast Iron Surface Plate - [Pike & Co.® Branded] w/Min 3yr Warranty Cutting-Edge Cast Iron Surface Plate - [Pike & Co.® Branded] w/Min 3yr Warranty](http://ws-eu.amazon-adsystem.com/widgets/q?_encoding=UTF8&ASIN=B00IEHMI1U&Format=_SL110_&ID=AsinImage&MarketPlace=GB&ServiceVersion=20070822&WS=1&tag=) |

| Bench Grinder | FESEQ300 | for general shaping and sharpening |  |