Screwdrivers: Difference between revisions

From DT Online

Created Article |

m Added category link |

||

| Line 102: | Line 102: | ||

| [[File:RightAngleDrive.png|150px|right]] | | [[File:RightAngleDrive.png|150px|right]] | ||

|} | |} | ||

[[Category:Levering, Twisting and Turning Tools]] | |||

Revision as of 08:51, 14 October 2015

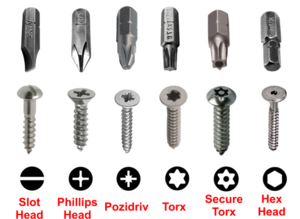

A manual Screwdriver is a basic tool which uses Torsion to tighten and loosen screws. They are described by the shape of their tip and these are available to suit the wide range of screw types now available.

Note:

Screwdrivers will rarely be located on the screw head such that their axes are exactly in line and so the screwdriver handle tends to describe a slight circular motion. For this reason a long handled screwdriver can usually exert a greater Torque than a short one because its handle will describe a larger circle and, as with a Wheel and Axle, this will generate a greater Mechanical Advantage

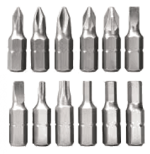

Some modern screwdrivers include a Rachet mechanism and can also be angled to access screws in confined spaces. Many will accept a range of interchangeable bits to cope with the different screw head designs as is the case of most Portable Electric Screwdrivers - and increasingly, these power screwdrivers are being used in preference to the traditional manual screwdriver.

Manual Screwdrivers

| Slot-Head Screwdriver (aka Flat-Blade Screwdriver) | Woodscrews were originally limited to Slot-Head which requires this design of Screwdriver. Care should be taken to select a blade size which closely matches the width of the woodscrew slot. They are now largely superceded by screwdrivers for more modern designs of screwhead but may still be used on restoration projects for example.

Note: If Slot-Head Woodscrews are used it is good practice, in the interest of aesthetics, to align all the slots on final tightening. |

|

| Philips and Pozidriv Screwdrivers | One of main advantages of screwdrivers with cross-shaped tips is that the screw and screwdriver together are self-centering. Their ease and speed of use has resulted in their becoming the most commonly used screwdriver today. They are less likely to slip and can transmit more torque but if too much torque is applied, the screwdriver winds itself out of the screw rather than breaking it - a feature built into the design of the system. Phillips screws were developed from an initial idea by J.P. Thompson but developed into a workable form by Henry Phillips who patented it and set up the Phillips Screw Company in Portland, Oregon in 1936 - the patent was lost in 1949. The Pozidriv screw is a further development as the result of a joint effort between American Screw Company and the Phillips Screw Company and can transmit greater torque. Phillips drivers should not be used with Posidriv screws (and vice versa) as they tend to ride out of the recess and round the corners of both the tool and screw recess. |  |

| Torx Screwdrivers | Designed for use with Torx Screws (also known as Star Screws), a type of screw head characterized by a 6-point star-shaped pattern, which are increasingly common in various manufactured goods. Torx screws were developed in 1967 by Camcar Texton. A tamper resistant variant, Security Torx, has a pin in the centre of the star to prevent use of normal screwdrivers. |  |

| Ratchet Screwdrivers | The provision of a Ratchet means screws can be driven in without changing grip on the handle making the process faster and smoother with less wear on the wrists. |  |

| Interchangeable Bits | The wide range of screwhead designs now available has resulted in the development of screwdrivers with interchangeable bits. These screwdrivers have bit holders which are often magnetic to ensure the bit (and the screw) is firmly held in use. Phillips bits are designated ‘PH’, Pozidriv ‘PZ’ and bits for Torx screws and stamped ‘T’ or ‘TX’. |  |

Special Purpose Screwdrivers

| Jewellers' Screwdrivers | Available in sets covering a range of small sizes and screw head types, these are used for high precision work in electronics, instrumentation and tightening spectacles for example. Most have a rotating cap on top of the handle that rests in the palm of the user’s hand allowing the screwdriver to be turned with finger tips without losing contact with the screw. |  |

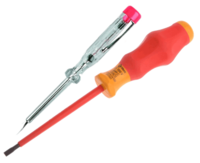

| Electricians' Screwdrivers | These are characterised by their fully insulated handles and blades to minimise the chance of electric shock. Mains Testers have neon light built in which lights up if it touches a live circuit but, if damaged, they can result in electric shock - non-contact electrical tester pens should be used to test for live circits.

Safety Point! Mains electricity can KILL! Work with mains electricity should be completed only by a qualified adult. |

|

Restricted Access Screwdrivers

| Stubby Screwdrivers | Being shorter than most screwdrivers, these are used to access to screws located in confined spaces. Their small size means they are often used with the palm of the hand but it is not easy to get as much purchase or torque as with a longer screwdriver. For this reason it is sometimes neccessary to grip the blade with a Vice-Grip or similar tools to gain additional Leverage |  |

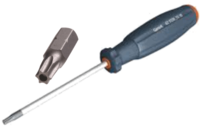

| Offset Screwdrivers | A manual screwdriver designed to reach screws in otherwise inaccessible places. |  |

| Angled Screwdrivers | As an alternative to 'Stubby Screwdrivers, these can also reach otherwise inaccessible screws and the Lever Action ensures there is sufficient torque for most screws. Interchangeable bits enable them to be used with most designs of screw heads. |  |

Powered Screwdrivers

| Electric Screwdrivers | These are increasingly common and much used for tasks such as building flat-pack furniture - which involves driving in lots of screws. The most basic type look like a traditional screwdriver and more powerful ones are similar to Portable Electric Drills - indeed, some drills have attachments plus speed and torque adjustment to enable them to be used for both tasks. Both drills and screwdrivers are available either mains driven (i.e. corded) or, more conveniently, battery powered. |  |

| Angled Powered Screwdrivers | Electric powered screwdrivers are available which can be set at different angles to facilitate access to hard to reach screws. |  |

| Right Angle Drive | One attachemnt for Portable Electric Drills is a right angled drive into which magnetic screwdriver bit holders can be gripped. |  |