Workshop Heat Area Example 1: Difference between revisions

From DT Online

m Added Note |

Added text and images |

||

| Line 17: | Line 17: | ||

[[File:HeatArea1.png|800px|center]] | [[File:HeatArea1.png|800px|center]] | ||

{| | |||

|- | |||

! Description | |||

! Code | |||

! Notes | |||

! Image | |||

|- | |||

| '''Moulding Bench''' | |||

| FESEQ317 | |||

| position near to casting area - if within a workshop it can be positioned as an island bench and used to screen off the casting area | |||

| [[File:Moulding bench M021.png|100px|right]] | |||

|- | |||

| '''Crucible Furnace''' | |||

| FESEQ316 | |||

| position near other heat equipment to share fume extraction - no other work takes place in the area during a 'pour' so can be in corner and safety spaces can overlap | |||

| [[File:CrucibleFurnace.png|100px|right]] | |||

|- | |||

| '''Combination Forge/Brazing Hearth''' | |||

| FESEQ315 | |||

| position such that fume extraction system can vent to outside wall | |||

| [[File:BrazingHearth.png|75px|right]] | |||

|- | |||

| '''Leg Vice''' | |||

| N/A | |||

| add if 'heavy' work is contemplated ''(e.g. for pre-vocational courses)'' - bench or stand mounted | |||

| [[File:LegVice.png|100px|right]] | |||

|- | |||

| '''Anvil''' | |||

| N/A | |||

| add if 'heavy' work is contemplated ''(e.g. for pre-vocational courses)'' - floor stand needed | |||

| [[File:Anvil.png|100px|right]] | |||

|- | |||

| '''Welding Bench''' | |||

| FESPF318 | |||

| provide both gas and electric welding and ensure fume extraction | |||

| <dtamazon product="B00KM41F5S" type="image">HEAVY DUTY PORTABLE WELDING TABLE WORK BENCH FOR MIG TIG WELDER</dtamazon> | |||

|- | |||

| '''Welding Screen''' | |||

| LESEQ637 | |||

| portable and must be provided in open workshops to protect eyes if electric welding is available | |||

| <dtamazon product="B00GAW6DU8" type="image">Langley WELDING CURTAIN 6 X 6 FT FIBREGLASS SCREEN FLAME RETARDANT WITH FRAME AND RINGS</dtamazon> | |||

|- | |||

| '''MIG Welding''' | |||

| LESEQ329 | |||

| for general purpose welding - provide also small portable oxy-acetylene gas welding set ''(e.g. for brazing, localised heating and welding thin sheet)'' | |||

| <dtamazon product="B00HNUYIQ2" type="image">Draper Tools 32728 Gasless Turbo MIG Welder</dtamazon> | |||

|- | |||

| '''Sheet Folder''' | |||

| LESEQ636 | |||

| fix to substantial bench - also available on floor stand or could be fixed to side bench - an alternative is a '''<dtamazon product="B00V3V4HXG" type="text">Box Folder</dtamazon>''' | |||

| <dtamazon product="B01N04FAWJ" type="image">165180 3-In-1 Manual Sheet Metal Shear Brake Roller Bending Machine 305mm</dtamazon> | |||

|- | |||

| '''Notcher''' | |||

| LESEQ340 | |||

| fix to substantial bench - also available on floor stand and larger version - alternatively use ordinary '''[[Bench Shears and Guillotines|Bench Shears]]''' | |||

| [[File:Notcher.png|100px|right]] | |||

|} | |||

{{Heat Area Buyers Guide}} | |||

[[Category:Accommodating Design and Technology in Secondary Schools]] | [[Category:Accommodating Design and Technology in Secondary Schools]] | ||

Latest revision as of 15:56, 19 February 2017

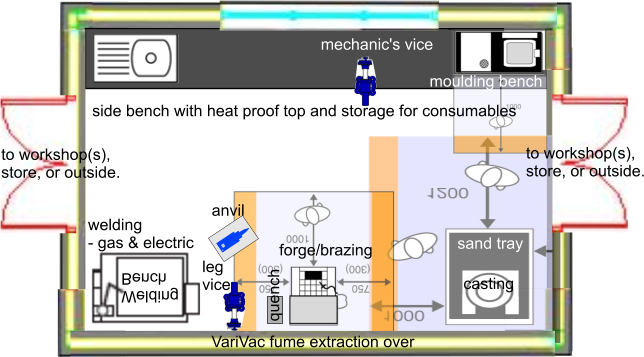

A Heat Area contains equipment for heating, forming and casting metals The Heat Area may be a space within a workshop, a separate bay off a workshop, or a separate room.

If in a separate area and of sufficient size, the Heat Area may also be a good location for metal forming equipment such as folding bars, bench shears, tube benders and bending rolls.

- Where possible, the Heat Area can be a shared resource between a group of workshops.

- Water should be provided but must be as far as possible away from the casting equipment.

- It must be well ventilated with fume extraction - to include localised extaction over welding and casting.

- It should be located with at least one external wall and ideally, but not essentially, with access to outside

Note: The light grey shade areas around each machine tool indicate the safety areas which should be left clear between machines. The orange coloured strips alongside the safety areas indicate permissible overlaps between them.

| Description | Code | Notes | Image |

|---|---|---|---|

| Moulding Bench | FESEQ317 | position near to casting area - if within a workshop it can be positioned as an island bench and used to screen off the casting area |  |

| Crucible Furnace | FESEQ316 | position near other heat equipment to share fume extraction - no other work takes place in the area during a 'pour' so can be in corner and safety spaces can overlap |  |

| Combination Forge/Brazing Hearth | FESEQ315 | position such that fume extraction system can vent to outside wall |  |

| Leg Vice | N/A | add if 'heavy' work is contemplated (e.g. for pre-vocational courses) - bench or stand mounted |  |

| Anvil | N/A | add if 'heavy' work is contemplated (e.g. for pre-vocational courses) - floor stand needed |  |

| Welding Bench | FESPF318 | provide both gas and electric welding and ensure fume extraction |  |

| Welding Screen | LESEQ637 | portable and must be provided in open workshops to protect eyes if electric welding is available |  |

| MIG Welding | LESEQ329 | for general purpose welding - provide also small portable oxy-acetylene gas welding set (e.g. for brazing, localised heating and welding thin sheet) |  |

| Sheet Folder | LESEQ636 | fix to substantial bench - also available on floor stand or could be fixed to side bench - an alternative is a Box Folder |

|

| Notcher | LESEQ340 | fix to substantial bench - also available on floor stand and larger version - alternatively use ordinary Bench Shears |  |

|

|

|

|

|

|

|

|

| Blacksmiths Forge |

Anvil Single Bick |

Blacksmiths Tongs |

Melting Furnace |

MIG Welder |

Fume Extraction System |

Heavy Duty Steel Work Bench with Cupboard and Drawer |

Galvanised Rectangular Planter |