Weaving: Difference between revisions

From DT Online

Added Weaving Methods |

mNo edit summary |

||

| Line 53: | Line 53: | ||

{{#ev:youtube|Zvohefehwpw|200x200|right||frame|loop=1&autoplay=0&playlist= | {{#ev:youtube|Zvohefehwpw|200x200|right||frame|loop=1&autoplay=0&playlist=4R8zMPfZqmE}} | ||

As before, the [https://en.wikipedia.org/wiki/Warp_and_woof '''Weft'''] can be packed down with a comb or dining fork as weaving progresses. This process is known as [https://en.wikipedia.org/wiki/Weaving#Process_and_terminology '''Beating-up or Battening''']. In small Hand Looms it can be done as described, or with the edge of a strip of wood. In more industrial scale looms the [https://en.wikipedia.org/wiki/Beater_(weaving) '''Beater'''] is part of a [https://en.wikipedia.org/wiki/Reed_(weaving) '''Reed'''] - part of the Loom which keeps the [https://en.wikipedia.org/wiki/Warp_and_woof '''Warp'''] threads separate and itself resembles a large comb. | As before, the [https://en.wikipedia.org/wiki/Warp_and_woof '''Weft'''] can be packed down with a comb or dining fork as weaving progresses. This process is known as [https://en.wikipedia.org/wiki/Weaving#Process_and_terminology '''Beating-up or Battening''']. In small Hand Looms it can be done as described, or with the edge of a strip of wood. In more industrial scale looms the [https://en.wikipedia.org/wiki/Beater_(weaving) '''Beater'''] is part of a [https://en.wikipedia.org/wiki/Reed_(weaving) '''Reed'''] - part of the Loom which keeps the [https://en.wikipedia.org/wiki/Warp_and_woof '''Warp'''] threads separate and itself resembles a large comb. | ||

Revision as of 13:48, 4 March 2017

Weaving is one of the oldest crafts and can be traced back to Neolithic times – approximately 12,000 years ago. The general principle of weaving was used to create fences or hurdles (aka Wattles), shelters and baskets from branches and twig. Eventually strips of plant fibres, (e.g. from Flax which is used to produce Linen) and wool were woven together to create textiles for clothing.

The Vikings used this technique to produce the large square sails which powered their ships - each oarsman or warrior would have had at least one person in his household, working for nearly a whole year, to weave the necessary textiles for woollen clothes and special rugs to keep out the cold, together with his part of the sail, before he could set out.

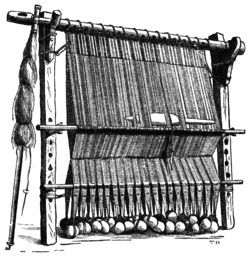

Most Viking households would have a Loom on which wider pieces of cloth could be produced. In addition, basic weaving techniques including: Finger Weaving; Tablet Weaving (see also YouTube demonstrations; and Peg Looms; together with Nålbinding and perhaps Spool Knitting could be used for narrower strips, cords and braids.

Cardboard Loom

A simple loom can be made out of a small rectangle of cardboard. A Cardboard Loom is a good way to introduce a basic weaving technique and to make small products such as woven Bookmarks, Bracelets or Coasters.

Take a piece of reasonably stiff card (e.g. about A5 size) and cut slits top and bottom about 10mm long and 10mm apart.

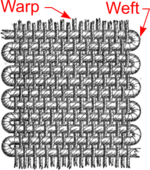

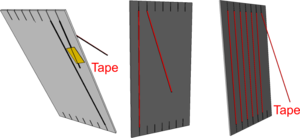

Use a length of twine or thin string, tape it to the back of the card, wrap it around the cut slits as shown, then tape the end to the back of the card as before. This will form the Warp of the finished weaving and should be non-stretch and strong enough to withstand a little Tension.

The Weft is the name given to the fibres which are woven over and under across the tensioned Warp threads to create the weave. the Weft can be thicker, softer and more ‘springy’ so that it can be packed down to fill in between the Warp threads as the weaving progresses - it is sometimes known as the fill and can be packed down with a comb or a dining fork for example. Knitting wool is a good choice of material and different colours can be used to create a woven design.

Frame Loom

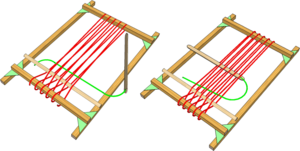

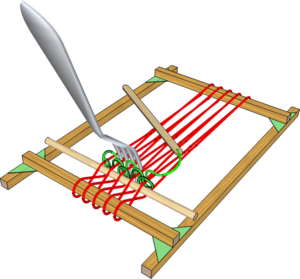

A more rigid Frame Loom can be made using Stripwood Technology techniques to join together strips of softwood using cardboard triangles.

The Warp threads can be wound around the frame as before, but this time both front and back threads can be used and the timber thickness provides some separation between alternate strands.

This separation is known as a Shed. This gap between alternate threads allows the Weft quickly to be passed through in one direction a least - although it still has to be woven over and under on the return pass.

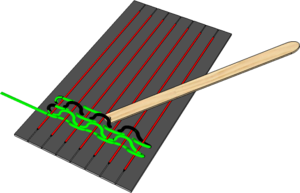

A piece of dowel is passed through the Shed to enlarge it and pack the Warp threads together at one end of the Loom. The Weft can be threaded through a Tapestry Needle or simply taped to a Lolly Stick to help guide it through from side to side. Used in this way, the Lolly Stick can be called a Shuttle.

The process of passing the Weft through from side to side is known as Picking and a single pass is called a Pick

As before, the Weft can be packed down with a comb or dining fork as weaving progresses. This process is known as Beating-up or Battening. In small Hand Looms it can be done as described, or with the edge of a strip of wood. In more industrial scale looms the Beater is part of a Reed - part of the Loom which keeps the Warp threads separate and itself resembles a large comb.

Tablet Weaving

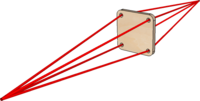

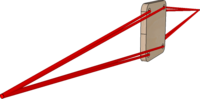

Tablet Weaving (aka Card Weaving) was widespread in Europe and Britain in the First Millennium AD. The technique is particularly useful to make belts, ties and narrow decorative banding, used as edgings on clothing and wider pieces of fabric.

Four Warps are threaded through holes in a Card or Tablet. Traditionally these were made from tree bark or bone but almost any rigid sheet material, such as cardboard or thin ply, would be suitable.

The Tablet separates the top two Warps from the bottom two and creates a Shed between them through which the Shuttle can be passed through, say right to left, when weaving.

Rotating the Tablet two quarter turns reverses the positions of the top and bottom Warps to form a new Shed for the return of the Shuttle, left to right, and this creates the weave.

A number of Tablets can be stacked together side by side and threaded with different coloured Warps. Some Tablets can be turned in one direction and some in another, and either clockwise or anti-clockwise, to generate quite complex patterns - and even lettering.

Peg Loom Weaving

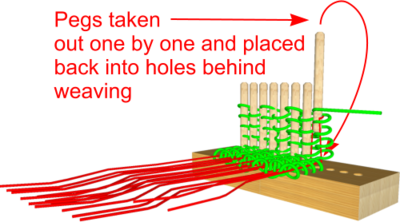

A Peg Loom can be made quite easily by drilling a row of holes along a length of timber (e.g. softwood about 45mm x 20mm). The holes should be a fairly loose fit on lengths of 6mm diameter dowel, each about 100mm to 150mm long.

The dowel ‘Pegs’ can be regarded as extensions to the Warps. Each ‘Peg’ may have a small hole drilled across its end through which a length of Warp is threaded, or a length ofWarp thread can simply be taped on to the end of each ‘Peg’.

Each threaded 'Peg' is inserted into a hole and the ends of adjacent Warps are tied together - this is necessary to prevent the weave coming off the end as it progresses.

The Warp is then simply woven between the ‘Pegs’ until the top is reached.

When the tops of the ‘Pegs’ are reached, each ‘Peg’ one by one, is pulled up through and out of the weave then replaced back into its location hole behind the woven segment.

Once all ‘Pegs’ have been replaced in this way, the weaving continues as before until the desired length of weaving is reached.

On completion, each ‘Peg’ is again pulled through the weaving and threads from adjacent Warps tied together.

Warp Weighted Loom

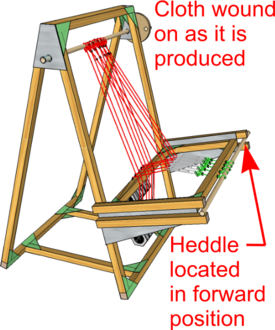

Warp Weighted Looms have been used since the Neolithic period. They comprise a simple rectangular frame made from locally found materials, which is laid at an angle (e.g. against a tree, wall or other structure) such that the Warps, traditionally with stones, hang down and are kept in Tension.

Alternate Warp threads are first draped over a cross rail part way up the front of the frame, and the remainder are left to hang vertically downwards.

This creates a Shed which the Shuttle can be passed through.

Each vertically hanging Warp thread passes through a loop of twine or cord which is tied to a bar across the front of the Loom frame. The weaver can pull this bar towards them to bring the rearmost hanging threads through to the front thus creating a new Shed for the Shuttle to be passed through on its return journey.

The arrangement which enables Sheds to be created in this way is known as a Heddle. The connections can be made of twine, cord or wire and in a Handloom, several Heddles can be operated by foot pedals to create complex weaving patterns. The process became fully automated with various developments leading to the Jacquard and Lancashire Looms.

A working model of a Warp Weighted Loom can be made using Stripwood Technology techniques to join together strips of softwood using cardboard triangles. Large diameter Nuts may be used for weights and Heddles can be made using Paper Clips.