Planes

From DT Online

The common Bench Plane has three main purposes in the workshop:

- to straighten a length of timber

- to smooth or flatten a surface

- to remove excess material

In addition, various specialist planes are used to create Grooves, Rebates, Moulding, Beading and Fluting.

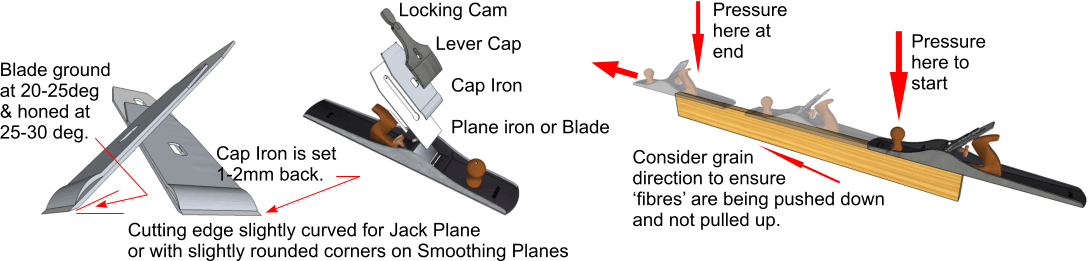

Plane blades, or ‘Plane Irons’, of all types are generally ground to an angle of 20-25 degrees and then ‘Honed’ with an Oilstone to a slightly steeper angle of 25-30 degrees to create a sharp cutting edge.

Blades of Bench Planes are set at approximately 45 degrees to the ‘sole’ of the plane and have a Cap Iron set slightly back from the cutting edge to break the shavings as material is removed. More specialist planes tend not to have a Cap Iron and are set at a shallower angle to the ‘sole’.

In modern working practice, much of the work of all the planes listed below is now achieved using a Portable Router, Portable Planer and Portable Sander (but for best quality work, planing and scraping may still be preferred because they produce a cleaner surface than sanding since the wood pores are not clogged with dust).

Bench Planes

| Jack Plane | This is the general purpose bench plane, around 350mm long, used for finished sizing and preparation of timber sections. |  |

| Smoothing Plane | The main purpose of this shorter plane, around 225mm long, is to create a smooth surface rather than straighten any edges. Planing tends to produce a superior finished surface to sanding. |  |

| Fore and Jointer Planes (aka Try Plane) | The main pupose of these longer planes is to produce a straight edge which they are able to do because of their long ‘sole’ - a Jointer Plane can be as much as 600mm long. |  |

| Block Plane | These small planes can be held in one hand and have a blade set at a shallow angle to enable them to slice across end Grain more easily. They are useful also for some finished shaping and chamfering of small parts for example. |  |

Special Purpose Planes

| Rebate Plane (aka Rabbet Plane) | The blades of all Rebate Planes protrude slightly from the side of the plane body to enable them to take shavings right up to the side of the Rebate - this can be imagined as a step along the length of a piece of timber. The plane is fitted with a depth stop and side fence to control the size of the finished Rebate. A Fillister Plane is very similar but with the addition of a small Spur to locate the rebate more accurately and to sever the wood fibres when cutting across the Grain. |  |

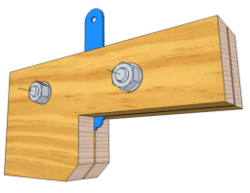

| Bull-Nose Rebate Plane | These have their blades set very close to the front of the plane to enable them to work close to the end of a stopped Rebate (i.e. one that does not continue right through to the end of the length of timber). Some have a completely removable front section to enable them to work to the very end of a stopped Rebate - these are sometimes known as Chisel Planes. |  |

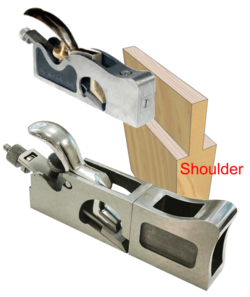

| Shoulder Rebate Plane | A rebate plane with a blade set at a shallow angle and no fence or depth stop, these can be used for final trimming of an existing rebate or, more traditionally, to finish the shoulders of the tenon in a Mortise and Tenon Joint. Some designs are in two or three sections enabling them also to serve as a Bull-Nose Rebate Plane with a removable front section. |  |

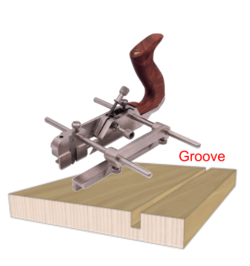

| Plough Plane | These have a side fence and depth stop plus a range of different width cutters to enable grooves to be cut along the length of a piece of timber. They can also cut small Rebates along the timber edge. |  |

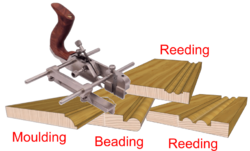

| Moulding Plane | Similar to a Plough Plane but with a range of shaped cutters to produce mouldings along the edge of a strip of timber or shaped beading if set in from the edge. Planes used for both moulding and ploughing (or grooving) are known as Combination Planes. |  |

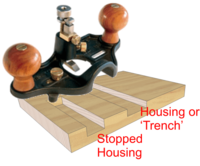

| Router Plane | Historically also known as a Witch's Tooth these single bladed planes are used for raking out the loose material after sawing across the edges of a Housing Joint for example. A Housing can be regarded as a groove across the Grain and is also known as a Trench or Dado. |  |

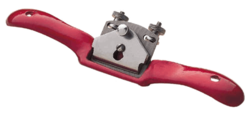

| Side Rebate Plane | These have two blades set at very shallow angles and are used to work the edges of grooves, housings or shoulders for example. |  |

| Compass Plane | These are fitted with a flexible spring steel ‘sole’ for planing concave or convex surfaces. They were traditionally used by shipwrights, carriage builders, and furniture makers, and some modern craftsmen still prefer them when it comes to smoothing long, sweeping curves - they have more mass and momentum than a spokeshave and are faster than sanding. |  |

Scrapers

| Cabinet Scrapers | Most commonly rectangular, about the size of a postcard, but available also in various shapes, these are made from high carbon steel and used to remove very small shavings as part of the finishing process. Scraping produces a cleaner surface than sanding since the wood pores are not clogged with dust. There is a skill to sharpening them and some woodworkers make their own from old handsaw blades. |  |

| Scratch Stock | Usually home made by clamping pieces of shaped and sharpened saw blade materials into a wooden stock, these are used to scrape away small amounts of materials to create beads or mouldings along strips timber. |  |

Traditional Shaping Tools

| Spoke Shave | Traditionally used to shape wooden wheel spokes - (for a fascinating insight into this craft see The Wheelwright's Shop by George Sturt), these are available with both flat and convex soles to enable them to be used for a variety of shaping process. |  |

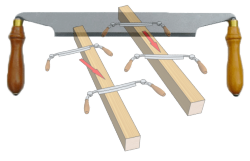

| Draw Knife | A traditional woodworking tool (aka Draw Shave) commonly used to remove bark from logs or roughly to shape timber ready for further work. They can be used with their bevel side up or, for finer work and more control, with the bevel side down and are drawn towards the operator from the centre of the log, turning it around as needed to complete the length. Best results are obtained with a slicing action, either by holding the blade at an angle to the work, or sliding it across, as it is drawn towards the user. |  |

| Axe | Traditionally used for splitting wood along its Grain, the Axe head is sharpened from both sides to create a narrow wedge which, as one of the Basic Machines, is able to generate a considerable side force or splitting action from each blow as a result of its Mechanical Advantage. |  |

| Adze | An ancient tool, similar to an Axe, but with a head at right angles to the handle, these are used for trimming and shaping baulks of timber. |  |

Note: Some traditional processes such as the use of a Draw Knife or Adze are more easily carried out on freshly felled, or ‘green’ timber (i.e. timber which has not yet been seasoned).

Activity

Visit a medieval building in your locality and take note of any large beams holding up a ceiling or floor above (e.g. The Undercroft of The Merchant Adventurers' Hall in York). Quite often these will be wider than they are deep, or at least square. Why is this when our common experience of bending a ruler held first flat and then ‘edge on’ tells us that beams are stiffer if they are deeper than they are wide?

How might such large beams have been produced? Perhaps the easiest way would be to select a straight tree trunk then, whilst freshly felled, ‘cleave’ it down its centre producing two semi-circular cross sections.

Dressing these with Axe and Adze would result in roughly rectangular (or square) baulks of timber but the ‘cleaved’ centre would probably be the flatest surface - and therefore the best one to present to the ceiling or floorboards.

Could this be the reason for over-sized, broader than deep beams in old buildings?