Thermoforming Plastics

From DT Online

[[File:]]

Description

The term Thermoforming could be taken literally to include any process which uses heat to create a 3D form - Blacksmithing for example. Throughout DT Online the term is used to include all those processes which employ heat to mould certain plastics.

Synthetic* Plastics are chemically produced from oil and a wide, possibly infinite, variety is possible, but they all fit into one of two groupings:

- Thermoplastics - these can repeatedly be softened by heating and will return to a rigid state when cooled.

- this group includes: Acrylic, Polycarbonate (PC), Polyethylene, and Polypropylene.

- Thermosets - these are initially ‘cured’ (or set), often by mixing with a ‘hardener’ which creates a heat producing (Exothermic) chemical reaction and, once set cannot be softened again by further heating.

- this group includes: Polyester Resin, Epoxy Resin, Bakelite and Melamine.

*Note: Several natural materials may also be classified as Plastics. These include: Cellulose, Horn, Amber, and Shellac.

DT Online includes as Thermoforming all processes in which Thermoplastics are heated to create products with a particular emphasis on methods of moulding flat sheet materials.

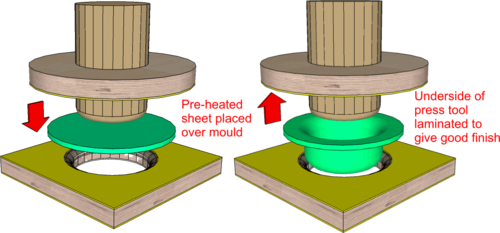

Press Moulding

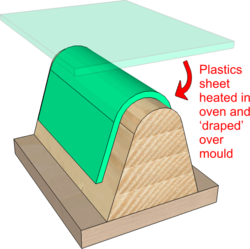

Drape Moulding

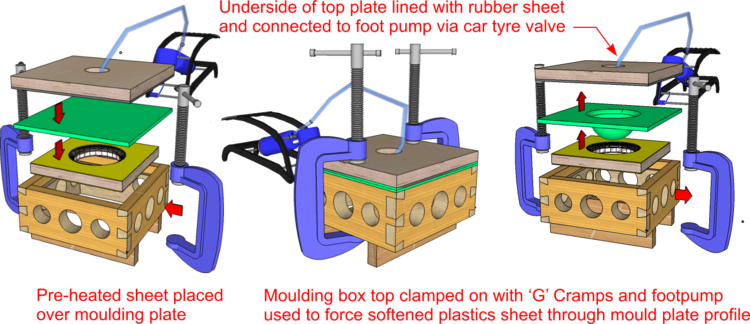

Blow Moulding

Line Bending