Precision Marking and Measuring

From DT Online

Description

When components have to be made to a precise measurement, in Engineering for example, it is important to be able to mark them out and test their dimensions as accurately as possible. A sharp Scriber is used to mark lines and the surface of bright drawn mild steel (BDMS) may first be coated with Marking Blue to ensure the lines can be seen easily (black rolled mild steel or cast iron could be rubbed with chalk for similar reasons).

Features and Applications

Engineering components can be irregular in shape and so a line or surface has to be chosen as the Datum - i.e. the place from where all measurements will start . The datum can be a centre line or a straight edge (in woodwork, this would be the Face Side or Face Edge). Often, and especially with castings or mouldings, the workpiece is held in relation to a flat surface to enable these reference lines to be scribed in the first place. Testing of properties such as flatness, roundness or parallelness can also be achieved by checking against a known flat surface.

Note: It is virtually impossible to make anything to an exact size. In practice components are made as accurately as they need to be to function. The degree of error allowable is known as the Tolerance and this varies with the type of work being done (e.g. the working parts of a car engine demand much closer tolerances than the garage to put the car in)

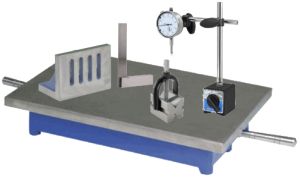

| Surface Plate | An accurately machined flat surface usually made from Cast Iron for stability (larger versions may be called a Surface Table). Work may be placed on here and heights measured from the surface for example. |  |

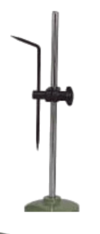

| Scribing Block | A device for holding a Scriber to mark lines at a given height for the datum surface |  |

| Surface Gauge | Similar to a Scribing Block but with the addition of a fine adjustment screw and sometimes a direct measurement read-out (then known as a Height Gauge) |  |

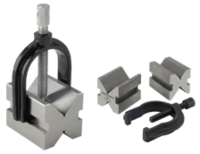

| Vee Blocks and Clamp | Used to hold round bar in position on the Surface Plate to enable it to be marked on.

Note: When longer bars need to be supported on two Vee Blocks only a single Clamp is used to ensure they stay flat on the Surface Plate and don't rock. |

|

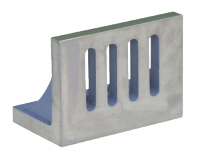

| Angle Plate | Used to fix work at right-angles to a Surface Plate or at an angle to it (also used to bolt work to for machining operations) |  |

| Dial Test Indicator (DTI) | Used to check that a component is parallel to the Surface Plate or flat or to check a bar is round by rotating it on Vee Blocks whilst a DTI is held against it. |  |