Thermoformed Bird Feeder

From DT Online

Design Brief

Design and make a wild bird feeder using mainly Acrylic sheet and Thermoforming processes.

Materials Available

- 3mm, 4mm and 5mm Acrylic sheet from which the main components are formed.

- Standard fixings as required (e.g. Machine Screws)

- Additions of other commonly available materials as needed (e.g. Manufactured Board)

Considerations

- Where will the feeder be placed to ensure it is easy to refill but away from the dangers imposed by predators (e.g. squirrels and cats)?

- Place feeders close to cover but not so close that branches will provide access to predators

- How will the feeder be mounted (e.g. on top of a post or suspended)?

- What will be placed in the feeder? (e.g. seeds or fruit)? If seeds, what types of seed and what size are they?

- If the bird food needs to be kept dry to avoid its rotting or going mouldy, how will ensure this?

- How will you ensure the feeder is easy to clean?

Note:

- Birds can become ill from leftover bits of seeds and fruit that have become mouldy or from droppings that have accumulated on feeder trays so feeders should be cleaned regularly.

- Many birds are killed by flying into windows because they see in them reflections of the sky. If windows are potentially a problem then placing the feeder close to them, or even against them, may avoid collisions because birds leaving will not have tme to be flying at top speed. Alternatively, place the feeder well away from any windows so they can be avoided all together.

Ideas

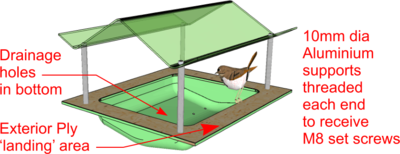

- Most feeders will comprise a main tray and a cover.

- The feeder trays will need drain holes to avoid their becoming water-logged and rotting the seed.

- Covers and trays can be held apart using spacers (e.g. 10mm dia aluminium drilled and tapped each end to receive 8mm set screws or made from hardwood dowel and woodscrews used as fastenings).

- The fixing screws into the spacer ends can be used also to secure a non-slip landing surface made from exterior ply for example.

Design Development and Construction

The main tray can be formed by Blow Moulding, Vacuum Forming or Press Moulding and the cover also plus .Line Bending if required.

Testing and Evaluation

- Do birds visit the feeder?

- Is the feeder easy to refill and to clean?

- How often does the feeder need refilling? Is it too big or too small?

- Are there any problems with visiting predators?

Further Work

- How would you adapt your design to fix to the outside of a window so the birds can be seen to feed from inside the house?

- Can you design and make a matching bird bath to provide a regular supply of fresh water (which doesn't freeze over in winter)?

- How would you rig a camera to take pictures of birds automatically when they come to feed?

Additional Materials

| Packet of (10) 22 mm 2 mm side pilot hole suction cup, |

|

| Packet of (4) 40mm suction cup with M4 screw with separate ridged nut |

|