Taps and Dies

From DT Online

Description

The most common way of cutting Screwthreads by hand is by using Taps and Dies.

Taps

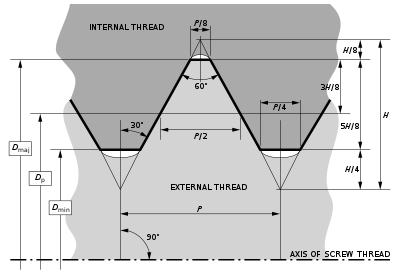

Taps are held in a Tap Wrench to cut a thread inside a drilled hole. Thread sizes are given as the diameter of the bar on which the external thread would be cut (i.e. the bolt diameter). It follows that the holes in which matching internal threads are cut must be less than the nominal thread sizes. They are known generally as the Tapping Sizes and are given in reference tables.

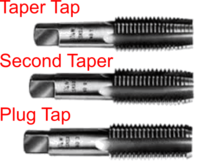

Taps are available in sets of three: Taper, 2nd Taper and Bottoming or Plug Taps (these have no taper at all). The Taper Tap is used first to get the thread started and in thin materials may be the only one needed. Bottoming or Plug Taps are used to continue threads in thicker materials or to finish a thread to the bottom of a blind hole (i.e. a hole that does not go right through the material).

Dies

The most common Dies are Circular Split Dies held in a Die Stock which has three adjusting screws: one screwed into the split to open the Die to its largest size, and two others either side, which can close up the Die once the central screw is slackened. The Die itself is also tapered on one side and, in this way, a single Circular Split Die can be opened up to start a thread then adjusted down to cut a thread such that it runs smoothly inside a nut or threaded hole and without too much slack. The end of the bar which is to receive the thread should always be slightly chamfered to make starting easier and if this is done accurately, on a lathe for example, the chamfer will also help to ensure the thread starts square to the bar to avoid drunken threads.

Cutting a Thread

When cutting a screwthread with either a Tap or a Die it is commonly accepted practice to advance one turn forwards then half a turn in reverse to break off the chip being cut. It is more important however, to feel the cutting action and gain a sense of when to cut and when to go backwards to cut off the chip - this may vary with the size of thread being cut and choice of material. Gaining such a feel for the cutting action is most important when using Taps to cut a thread inside a blind hole. The danger is that if too much force is applied as the Bottoming Tap reaches the bottom of the hole, it may break. Note also that chips of metal will fall to the bottom of the hole during the cutting operation and these need frequently to be cleared out.

Tap Wrenches

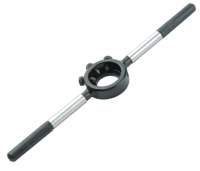

| Bar type Tap Wrenches are the most commonly used tool to hold Taps and turn them to cut a screw thread. Usually , they have hardened steel jaws and Knurled handles for extra grip. Long handles provide the Leverage required, especially when using larger diameter taps.

|

|

| ‘T Handle’ type wrenches hold the tap in a Collet Chuck which is tightened by twisting a Knurled nut. They can provide more ‘feel’ when cutting smaller threads and those with a Ratchet action such that they can rotate forwards and backwards, are ideal for use in confined spaces. |  |

All Tap Wrenches can also be used with Reamers, Screw Extractors and other tools with a square shank.

Diestocks

| Circular Split Dies are held in a Die Stock so that they can be turned to cut an external thread on a bar (e.g. to make a Bolt). The Die Stock has three adjustment screws. To start a thread, the Die is opened to its widest by the central screw which is driven into the adjustment split. Subsequently, successive cuts are taken with the centre screw progressively slackened and the outer screws tightened, until a close fitting thread is achieved. |  |

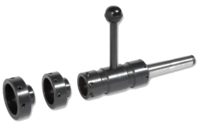

| A Tailstock Die Holder makes good use of the true alignment between a Centre Lathe Tailstock and Chuck. They are fitted with a Morse Taper such that they can be gripped accurately in the tailstock quill. With the power off the lathe chuck is held by hand (or the lathe placed in a low gear, for greater turning resistance, or its spindle locked), the handles of the Tailstock Die Holder can be rotated forwards and backwards to produce concentric threads on the bar stock. |  |

Safety Point! Tailstock Die Holders are designed for thread cutting only by hand, using the lathe for thread alignment, but without using the lathe power. NEVER turn on the lathe power while holding the Die Holder handles. This can be extremely dangerous, even for short lengths of thread.