Steam Bending

From DT Online

Historically, if curved shapes were required in wood, suitably shaped trees and branches (i.e. Crucks) would be found in the local forest and split (or cleaved) down the centre. More commonly, curved shapes can be cut from the solid, Cold Moulded or Steam Bent as described below.

Note:

Simply cutting a curved shape out of a plank of wood may result in places where the wood grain is oriented more across the width than along the length of the piece. This is known as Short Grain and is a weakness which is likely to break under load.

Introduction

The cell structure of wood softens when heated above boiling point (1000C). Once softened, it becomes pliable and can be bent into various shapes which are retained when the wood cools again. Steam Bending is an ancient process, much used in boat building and furniture construction (e.g. Windsor Chair and by Michael Thonet). Most timbers will Steam Bend satisfactorily but harder woods and thicker sections take longer to steam. Temperate hardwoods (e.g. Oak, Ash, Beech, Cherry, Birch, Poplar, Elm, Sycamore, Walnut) are a good choice and straight grained timber is always best. 'Green', or freshly felled unseasoned, timber Steam Bends very well (and is fully seasoned after the process). It is advisable to immerse seasoned timber in water for 24 hours prior to bending.

Note:

Experimentation is necessary: if the wood is too dry it will crack and if too wet it may crumple on the inside of some bends. Wood bends best when its moisture content is around 20% to 30%.

Heating the Timber

- Boiling in water

One of the simplest methods used to soften small pieces of timber is to boil them in a pan of water. Immerse thin strips of wood in boiling water for about 10mins and experiment with thicker sections by testing every 5mins. or so.

- Using a Heat Gun or Heated Paint Stripper

Thin strips of wood can be soaked in water and heated with an electric Heat Gun or similar to soften it sufficiently for small bends, either free-hand or around a former. Care must be taken to ensure the wood does not scorch or char since this would make it brittle and impossible to bend without breaking.

- Using a Microwave

Small pieces can also first be soaked in water then wrapped in wet cloths or paper towels and heated in a Microwave. This technique has the advantage of being the quickest and thin strips may become pliable after only 20 or 30 seconds. It is important to check progress every 5 or 10 seconds to ensure the towels do not dry out in the process.

- Using a Domestic Iron or Steam Iron

The ends of previously soaked thin strips of wood or veneer can be clamped to a former, covered with a wet cloth, then coaxed round simple curves with an ordinary domestic iron. The iron also serves to some extent as a Compression Strap to stop fibres on the outer surface breaking out during the operation.

- Heated Bending Iron

Electrically heated Bending Irons are commercially available but, with care, strips of timber can be bent over a length of steel or aluminium tubing with a Gas Torch played through its centre to provide the heat. Strips of timber are repeatedly soaked in water and worked over the heated tubing to produce the required bend. The heat from the tube generates steam locally to soften the wood where it is in contact with it. The technique is used most commonly in the manufacture of musical instruments (e.g. violin and guitar bodies).

- Heated Press Tool

Commercial guitar makers compress veneers in an electrically heated metal lined two part mould to form guitar bodies.

- Plastic Bag

The timber to be bent can be placed inside a clear plastics bag or tube into which is fed a hose carrying steam from a kettle or similar. The main advantages of this method are that the timber can be seen as it is worked and it can continue to be steamed as it is pulled and clamped around the former.

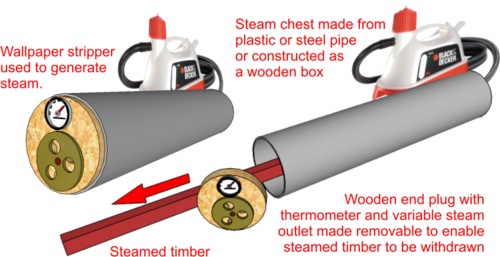

- Steam Box

Steam can be generated by an electric wallpaper stripper or even a kettle, for example, and piped into box or tube containing the length of timber to be bent. This is the most universal method for steaming timber since the box can be made to whatever length is required and the timber steamed continuously until pliable which allows thicker sections to be worked - steam for approximately 1 hour for every 25mm thickness.

A length of plastics or metal tube can be used or the box can be purpose-made from Softwood or Exterior Ply for example. There is a danger that some plastics may soften when heated and metal tubes would be hot to touch whereas a wooden Steam Box avoids both problems. The box or tube should have a vent to allow steam to pass through (Safety Point! : never allow the steam to become pressurised) and it is useful to add a simple oven type thermometer. There needs to be a means of access to remove the steamed workpiece and some Steam Boxes include racking inside to support lengths of timber.

Safety Point! Regardless of which method of heating the timber is used, it will be boiling hot and could scald! Take care and handle steamed timber only with thick gloves therefore.

Steam Bending Process

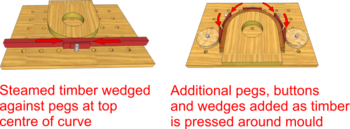

In general, the steamed timber is pulled around a former whilst it is still hot and left in position until cool. The formers, or bending Jigs, are cut from timber to be the same shape as the finished curve and often include several holes or slots into which clamps can be positioned as shown.

Note: Relatively shallow forms, perhaps constructed from a lattice or layers of steamed thin strips of timber or veneer, could be placed in a Vacuum Bag to be moulded.

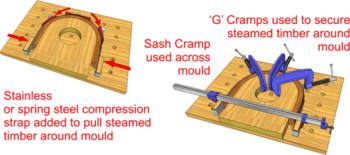

The workpiece is firmly clamped to the former with wedges, or 'G' Cramps for thicker sections and often starting from the centre or one end of the curve, then pulled round adding clamps as it progresses. The timber is most likely to break out on the outside of the bend where it is in Tension. To help avoid this, a Compression Strap, comprising a thin strip of Stainless or Spring Steel, can be added to the outside and used to pull the wood around the former clamping it tight to the wood as the curve is produced.

After bending, the wood can be left clamped to the former to dry for a day or more or, once it is cool, transferred and clamped to a Drying Jig, which is the same profile as the former but need not be quite so robust. In either case, if a Compression Strap is used, this should be removed after an hour or so otherwise the wood surface may become discoloured. Finally, the shaped timber can be trimmed, further worked on, sanded and finished as required.

'How to' Videos

Click on video top bars to enlarge

| Using a Steam Box | Using a Microwave | Shaker Box Construction | Traditional Walking Stick |

|

|

|

|

|

|

| Wood Veneer |

Wallpaper Stripper |

Work Gloves |

Temperature Dial |

Heat Gun |

Bending Iron for Violin |