Category:Threading Tools

From DT Online

Screwthreads may be cut by hand using Taps and Dies.

As with many cutting operations, a cutting lubricant can be helpful when cutting a screwthread. But not all metals need an extra lubricant to be applied. The different lubricants can be summarised as follows:

- Cast Iron - this should be cut dry because, by its nature (i.e. contains in excess of 2% Carbon), the free Carbon within it acts as a cutting lubricant.

- Steel - use oil-based Cutting Fluid - ideally in paste form.

- Non-Ferrous metals - in general, White Spirit can be used.

When cutting a screwthread with either a Tap or a Die it is commonly accepted practice to advance one turn forwards then half a turn in reverse to break off the chip being cut. It is more important however, to feel the cutting action and gain a sense of when to cut and when to go backwards to cut off the chip - this may vary with the size of thread being cut and choice of material. Gaining such a feel for the cutting action is most important when using Taps to cut a thread inside a blind hole. The danger is that if too much force is applied as the Bottoming Tap reaches the bottom of the hole, it may break. Note also that chips of metal will fall to the bottom of the hole during the cutting operation and these need frequently to be cleared out.

Pages in category "Threading Tools"

The following 8 pages are in this category, out of 8 total.

Media in category "Threading Tools"

The following 13 files are in this category, out of 13 total.

-

DieNut.png 236 × 236; 22 KB

-

DieStock.png 448 × 384; 17 KB

-

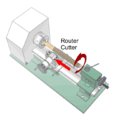

LatheScrewCutting.png 629 × 648; 42 KB

-

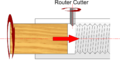

RouterJig.png 908 × 467; 45 KB

-

ScrewBox.png 250 × 250; 73 KB

-

SplitDie.png 308 × 308; 45 KB

-

StudExtractors.png 328 × 328; 28 KB

-

TailstockDieHolder.png 500 × 321; 56 KB

-

TapExtractor.png 406 × 434; 18 KB

-

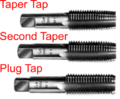

Taps2.png 462 × 383; 44 KB

-

TapWrench.png 338 × 338; 10 KB

-

TapWrenches.png 818 × 619; 53 KB

-

ThreadChasers.png 596 × 556; 44 KB