Grooved Seam Joint

From DT Online

Description

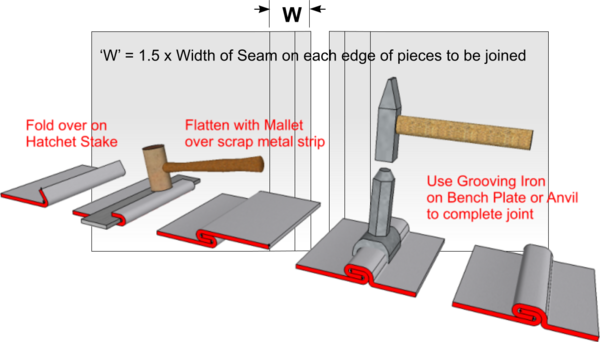

Grooved Seam are a type of self-locking joint used commonly in the fabrication of cylindrical and conical objects. The Seam can be on the outside or on the inside. The extra material allowance for a Grooved Seam is 3 times the width (W) of the Seam, one half of this amount being added to each edge (Note: up to 4 times the material thickness may also need to be added for thicker sheet materials)..

Making a Grooved Seam

- Mark out half the width of the Seam on each end of the piece to be joined.

- Fold initially to an acute angle using Folding Bars and Hatchet Stake or Bench Folder.

- Use a Boxwood or Rawhide Mallet to beat it over a scrap piece of metal of the same thickness on a Bench Block or similar surface.

- Hook together to two shallow 'U'-shaped ends and lock them together using a Grooving Iron as shown.

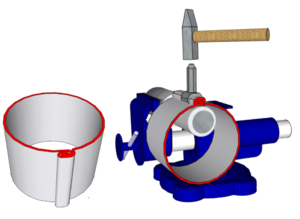

- (the process is similar for an 'Inside Seam' with the exception that a Grooving Iron is held upside down in a Vice and the joint is set down into it using a Boxwood or Rawhide Mallet).

- When locking a Grooved Seam on the outside of a cylinder or conical object, the workpiece can be supported on a Mandrel Stake, Triblet, Anvil or Funnel Stake.

- Grooved Seams on the inside of cylinders and cones can be supported by a rail extending out of the side of the Vice with a suitable groove cut along its top surface (alternatively, a temporary rail can be created by clamping together three steel strips and setting the middle one down a little to form the centre groove).

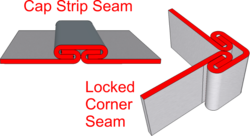

Cap Strip Seam

A Cap Strip (aka Drive Slip) can be used to draw together two halves of a joint to make a Double Groove Joint. It is a method often used to assemble air-conditioning and heating ducts.

A similar strip can be used to create a Locked Corner Seam which is useful for the assembly of rectangular shapes.