Files and Rasps

From DT Online

Description

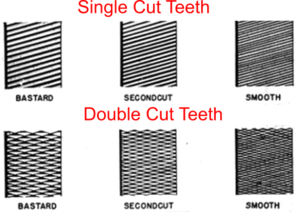

Files are abrading tools used to remove small amounts of metal and plastics. The teeth of a file are known as the ‘cut’ and are created by a ‘single cut’ across the file blade or a ‘double cut’ which creates diamond shaped teeth. Common ‘cuts’ of files are graded as smooth, second cut and bastard cut.

Range of Files, Rasps and similar abrading tools

| Engineers' Files | - The common cross-sections of files are hand, flat, round, half-round, triangular, square, and knife edge. A Flat File (aka Mill File) has a tapered blade whereas a Hand File is parallel and has a safe-edge to enable filing up against a shoulder - these are the most commonly used files. Triangular (aka Three Square) files are useful for working one side of a square shape whilst avoiding the others. They are also available as saw sharpening files. |

| Warding Files | - small tapered files for cutting fine slots as used by locksmiths when making Warded Locks. |

| Needle Files | - small files available in a variety of shapes for small intricate work in jewellery for example. |

| Dreadnought (curved teeth) and Millenicut (straight teeth) Files | - these are very coarse, deeply cut and sharp files used for rapid removal of soft materials such as aluminium, copper and some plastics. |

| File Card | - this is a brush with metal bristles used to remove waste metal particles from in between file teeth. This clogging of teeth is known as ‘pinning’ and may be reduced by first rubbing a file with chalk. |

| Rifflers | - these are medium or small size files in a variety of shapes and often curved at the end to enable them to work the bottom of recesses such as when die making. Also available with rasp-like coarser teeth for similar work in wood. |

| Surform | - used to shape wood. Surform blades are made from a perforated steel strip with the rim of each hole sharpened to form a cutting edge. |

| Rasps | - similar tools to files but are used to shape wood and tend to have coarser teeth |

Using Files

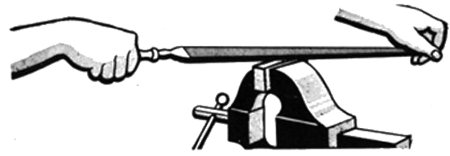

- Grip the file with both hands, file close to the vice and always try to arrange the work such that filing is done horizontally as shown. File at and angle and change stance and direction of filing from time to time such that the file marks left previously can easily be seen - this will help improve accuracy by guiding further filing. The aim should be to progress along the full length to be filed with each full stroke of the file.

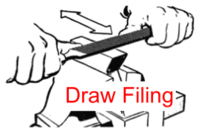

- Draw Filing is done by holding a file with one hand each end across the edge of material and drawing it backwards and forwards to smooth out file marks.

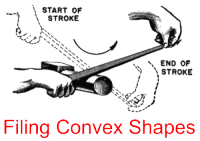

- When filing convex curves the file should rolled around an imaginary opposite curve as shown

|

|

|

Notes:

- Use new files to file Brass. This will 'work in' the file and a used file will tend to skid over the surface.

- Regulary brush across the file teeth with a File Card to clean out waste particles.

- To avoid Pinning (i.e. filings remaining stuck between the file teeth) when filing Aluminium, rub chalk into the file teeth.