Threading Tools: Difference between revisions

From DT Online

(Created Category) |

m (Changed text) |

||

| Line 1: | Line 1: | ||

'''[[Nuts, Bolts and Washers|Screwthreads]]''' may be cut by hand using | '''[[Nuts, Bolts and Washers|Screwthreads]]''' may be cut by hand using '''[[Taps and Dies]]''' or on a '''[[Centre Lathe]]''' which is fitted with a screw-cutting gearbox | ||

As with many cutting operations, a cutting lubricant can be helpful when cutting a screwthread. But not all metals need an extra lubricant to be applied. The different lubricants can be summarised as follows: | A suitably shaped lathe tool, or a '''Router''' with a similar cutter, can be clamped into a '''[[Centre Lathe]]''' '''Toolpost''' or '''Cross Slide''' and an external thread cut making use of the '''Leadscrew''' gearing to advance the tool or cutter one screw thread '''Pitch''' for each revolution of the lathe. Simlarly, a '''Boring Tool''' can be shaped and used to cut internal threads. | ||

As with many cutting operations, a cutting lubricant can be helpful when cutting a screwthread, either by hand or machine. But not all metals need an extra lubricant to be applied. The different lubricants can be summarised as follows: | |||

* [https://en.wikipedia.org/wiki/Cast_iron Cast Iron] - this should be cut dry because, by its nature ''(i.e. contains in excess of 2% Carbon)'', the free Carbon within it acts as a cutting lubricant. | * [https://en.wikipedia.org/wiki/Cast_iron Cast Iron] - this should be cut dry because, by its nature ''(i.e. contains in excess of 2% Carbon)'', the free Carbon within it acts as a cutting lubricant. | ||

* [https://en.wikipedia.org/wiki/Steel Steel] - use oil-based [https://en.wikipedia.org/wiki/Cutting_fluid Cutting Fluid] - ideally in paste form. | * [https://en.wikipedia.org/wiki/Steel Steel] - use oil-based [https://en.wikipedia.org/wiki/Cutting_fluid Cutting Fluid] - ideally in paste form. | ||

* [https://en.wikipedia.org/wiki/Non-ferrous_metal Non-Ferrous metals] - in general, [https://en.wikipedia.org/wiki/White_spirit White Spirit] can be used. | * [https://en.wikipedia.org/wiki/Non-ferrous_metal Non-Ferrous metals] - in general, [https://en.wikipedia.org/wiki/White_spirit White Spirit] can be used. | ||

Revision as of 13:54, 15 November 2015

Screwthreads may be cut by hand using Taps and Dies or on a Centre Lathe which is fitted with a screw-cutting gearbox

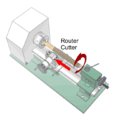

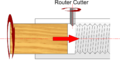

A suitably shaped lathe tool, or a Router with a similar cutter, can be clamped into a Centre Lathe Toolpost or Cross Slide and an external thread cut making use of the Leadscrew gearing to advance the tool or cutter one screw thread Pitch for each revolution of the lathe. Simlarly, a Boring Tool can be shaped and used to cut internal threads.

As with many cutting operations, a cutting lubricant can be helpful when cutting a screwthread, either by hand or machine. But not all metals need an extra lubricant to be applied. The different lubricants can be summarised as follows:

- Cast Iron - this should be cut dry because, by its nature (i.e. contains in excess of 2% Carbon), the free Carbon within it acts as a cutting lubricant.

- Steel - use oil-based Cutting Fluid - ideally in paste form.

- Non-Ferrous metals - in general, White Spirit can be used.

Pages in category 'Threading Tools'

The following 8 pages are in this category, out of 8 total.

Media in category 'Threading Tools'

The following 13 files are in this category, out of 13 total.

- DieNut.png 236 × 236; 22 KB

- DieStock.png 448 × 384; 17 KB

- LatheScrewCutting.png 629 × 648; 42 KB

- RouterJig.png 908 × 467; 45 KB

- ScrewBox.png 250 × 250; 73 KB

- SplitDie.png 308 × 308; 45 KB

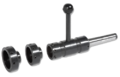

- StudExtractors.png 328 × 328; 28 KB

- TailstockDieHolder.png 500 × 321; 56 KB

- TapExtractor.png 406 × 434; 18 KB

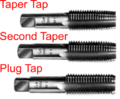

- Taps2.png 462 × 383; 44 KB

- TapWrench.png 338 × 338; 10 KB

- TapWrenches.png 818 × 619; 53 KB

- ThreadChasers.png 596 × 556; 44 KB