Spaghetti Bridge Challenge

From DT Online

What to Make:

(Designers might call this the Design Brief and/or the Specification)

Design and build a bridge out of (uncooked!) spaghetti to carry a load of 1kg across a gap of 500mm using as little spaghetti as possible. The bridge must include a 50mm wide roadway which will allow a model vehicle (i.e. 1/50th scale approximately) to roll freely along it.

What to Use:

- Any variety of spaghetti may be used but not macaroni (tubular pasta) or lasagne (sheet pasta)

- Any suitable adhesive may be used but not sellotape or any other adhesive tapes.

Safety Point! A Hot Glue-Gun, Balsa Cement and Epoxy have each proved effective but care must be taken to follow safety advice when using such adhesives.

Things to think about:

Spaghetti is a brittle material and very unforgiving if loaded incorrectly. Samples of spaghetti can be tested to establish that it has a U.T.S. of around 15N/mm2 and has a Young's Modulus similar to aluminium. It may perform quite well if used in Tension as a Tie but is likely to fail by Buckling if subjected to Compression as a Strut (press a length of spaghetti down onto a hard surface to see this).

Note: If you note the length of spaghetti used and press down on to small scales to take a reading, sufficient data will be recorded to be able to confirm the Young's Modulus of spaghetti - see Euler's Buckling Equation.

Some ideas:

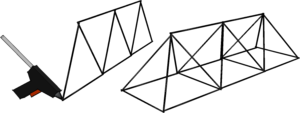

Research Common Bridge Types and famous Truss Bridges in particular (e.g. Sydney Harbour Bridge;Golden Gate Bridge; Silver Jubilee Bridge) and learn about the many variations of truss design.

Ways of Making:

Make sketches of bridge ideas and try to work out where the forces will act, estimate their size and whether they are in Compression or Tension.

When subjected to Compression, spaghetti will need to be bundled together or formed into Trusses. Bundling will result in a much heavier Strut than building a Truss even if only spot-glued every few centimetres. For strength, overlap joints when gluing together a Truss rather than trying to use a Butt Joint. Badly glued joints are a potential point of failure.

Draw your bridge design full-size (e.g. using squared paper) and use this to set out and glue together the separate Truss Frames required before gluing them together and enclosing the roadway.

Testing Final Design:

- Accurately weigh the completed bridge (i.e. to a 1/10th of a gram if possible).

- Support the finished bridge as shown ensuring that the gap between supports is exactly 500mm (e.g. use block of wood or house bricks for the supports).

- Suspend the hanger from a slotted mass set below the centre of a 100mm x 50mm piece of thin ply or MDF which is resting on top or inside the bridge on the centre of the roadway as shown.

- Add the slotted masses slowly and gently to the hanger until the specified load of 1kg has been achieved (or not!).

The winner is the lightest bridge which successfully spans the gap, allows a car to roll along it and carries the load as specified.