Pneumatics Flow Control

From DT Online

Description

In a pneumatic circuit there is always a delay between operating a valve and the piston moving. This is because the air takes time to flow through the pipes and to build up enough pressure to move the piston.

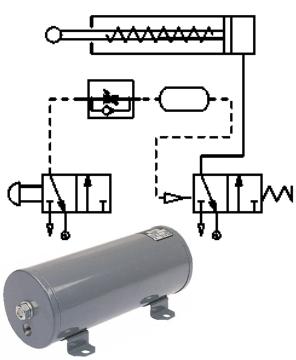

By introducing a reservoir into a pipe, we can increase the amount of time required to build up enough pressure, and hence build time delays into our circuits.

Features and Applications

In the circuit shown, when the valve is switched on, air flows slowly through the flow control valve and fills the reservoir. When pressure has built up, the pressure operates the pilot input to the second valve and the cylinder is activated.

Note: In this circuit we have used a uni-directional regulator to allow the stored air in the reservoir to exhaust quickly once the first valve is switched off, and hence the piston returns to its original position almost immediately as the first valve is switched off.

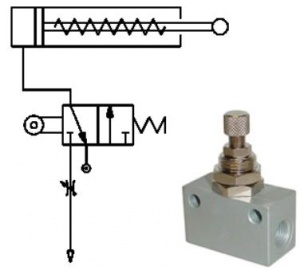

Inserting a Flow Control Valve in the exhaust circuit of a cylinder will slow down the movement of the cylinder as the exhaust air has to work hard to escape through the restriction. This is known as metering out.

Shown below are the symbols for : a flow control valve set at a fixed value, a valve with an adjustable setting and a valve which allows flow in one direction only (uni-directional)- achieved the adding a check valve as indicated.

|

|

|

|

|

|

|

|

| Air Compressor |

4mm Air Line Connectors |

4mm Airline Adaptors |

Air Line Manifold |

Pneumatic Mechanical Valve |

Pneumatic Logic Air Valves |

Pneumatic Actuating Cylinders |

Pneumatic Construction Kits |