Soldered Lap Joint

From DT Online

Description

When forming sheet metal into boxes, cylinders or cones for example, it is usually necessary to join the ends together. This is known as making a Seam and the simplest method is to overlap and solder to make a Soldered Lap Joint.

Making the Joint

- An allowance equal to the width of the overlap must be added to the length of sheet metal used.

- Ensure the joining surfaces are clean, apply Flux and bring the pieces together.

- Small pieces may hold themselves together but larger, more complex or 'springy' joints will need to be held in place until Soldered.

- Use weights, clips, split pins or wire, for example, to stop the pieces moving out of place but ensure that no large section of metal come close to the joint (these would conduct heat away and make it more difficult to Solder).

- If thin Tinplate is used, this is not very conductive and already Tinned, so should joint very quickly and easily using an Electric Soldering Iron.

- Larger joints in thicker and more conductive materials may need to be Soldered using a Gas Heated Iron - especially if the work is done outdoors.

Off-set Lap Joint

It is sometimes desirable to have one of the surface left flat and smooth, or 'flush', after joining. This is known as an Off-set Lap or Countersunk Lap joint and is achieved by creating a small 'step' along one of the two joining edges with a depth equal to the metal thickness.

A suitable 'step' can be formed by placing a strip of scrap metal under one of the edges and laying down the workpiece on to a Bench Block or similar surface. The width of the strip should equal that of the required overlap and its thickness the same as the metal being joined. A Grooving Iron can then be struck to set the metal down on to the block and create the required 'step'.

The process of creating the 'step' is known as Joggling and a specialist tool called a Joggler is available to simplify the task.

Corner Lap Joints

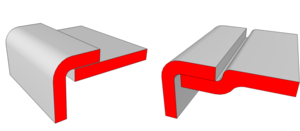

Both Plain Lap and Off-set Lap joints can be configured for corner joints as shown.

The smooth, or 'flush', surface of all Off-set Lap Joints can be arranged to be either inside or outside the formed object.