Timber Defects: Difference between revisions

From DT Online

Added Category |

mNo edit summary |

||

| (9 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

=====Introduction===== | =====Introduction===== | ||

A '''Defect''' is taken to be any irregularity | A '''Defect''' is taken to be any irregularity occurring in or on the timber which may lower its strength, durability, utility value or diminish its appearance. '''Defects''' may be 'natural' which occur whilst the tree is growing, or 'artificial' as a result of poor conversion, seasoning or handling after felling. | ||

| Line 12: | Line 12: | ||

A most commonly observed defect in timber are [https://en.wikipedia.org/wiki/Wood#Knots '''Knots''']. These occur where branches have grown out of the tree trunk. They are more common in some timbers ''(e.g. [https://en.wikipedia.org/wiki/Pine '''Pine'''])'' than others. ‘'''''Live Knots'''''’ are fully integrated with the surrounding timber. They may reduce strength and increase difficulty working the timber but are mainly a visual defect - indeed, '''Knotty Pine''' is used to decorative effect. ‘'''''Dead Knots'''''’ by contrast are not integrated and often surrounded by '''[[Tree Structure|Bark]]''' and may show signs of decay. They are loose and cannot be relied on to stay in place, often dropping out, leaving a hole which needs to be filled. | A most commonly observed defect in timber are [https://en.wikipedia.org/wiki/Wood#Knots '''Knots''']. These occur where branches have grown out of the tree trunk. They are more common in some timbers ''(e.g. [https://en.wikipedia.org/wiki/Pine '''Pine'''])'' than others. ‘'''''Live Knots'''''’ are fully integrated with the surrounding timber. They may reduce strength and increase difficulty working the timber but are mainly a visual defect - indeed, '''Knotty Pine''' is used to decorative effect. ‘'''''Dead Knots'''''’ by contrast are not integrated and often surrounded by '''[[Tree Structure|Bark]]''' and may show signs of decay. They are loose and cannot be relied on to stay in place, often dropping out, leaving a hole which needs to be filled. | ||

[[File:ShakesChecks.png|150px|right]] | |||

=====Shakes and Checks===== | =====Shakes and Checks===== | ||

| Line 20: | Line 20: | ||

'''Checks''' are a separation of the wood normally occurring across or through the '''[[Tree Structure|Annular Rings]]'''. They are the result outer layers of wood drying out and shrinking around the still moist inner layers. One reason for '''[[Timber Conversion|Converting]]''' timber soon after felling is to minimise this problem. | '''Checks''' are a separation of the wood normally occurring across or through the '''[[Tree Structure|Annular Rings]]'''. They are the result of outer layers of wood drying out and shrinking around the still moist inner layers. One reason for '''[[Timber Conversion|Converting]]''' timber soon after felling is to minimise this problem. | ||

=====Shrinkage Defects===== | =====Shrinkage Defects===== | ||

As timber dries out, during ''[[Seasoning]]''' and afterwards, shrinkage occurs mainly across the [https://en.wikipedia.org/wiki/Wood_grain '''Grain'''] with only the slightest movement along the [https://en.wikipedia.org/wiki/Wood_grain '''Grain''']. The amount of [https://en.wikipedia.org/wiki/Wood_drying#Shrinkage_and_swelling '''Shrinkage'''] across grain varies dependent upon the orientation of the '''[[Tree Structure|Annular Rings]]''' which themselves tend to shorten and straighten out as wood dries. Also, newer wood will tend to shrink more than older wood so the side of a board nearest to the '''[[Tree Structure|Bark]]''' for example, will shrink more than that towards the tree centre. This has various consequences for the way boards of timber react when dried: | As timber dries out, during '''[[Seasoning]]''' and afterwards, shrinkage occurs mainly across the [https://en.wikipedia.org/wiki/Wood_grain '''Grain'''] with only the slightest movement along the [https://en.wikipedia.org/wiki/Wood_grain '''Grain''']. The amount of [https://en.wikipedia.org/wiki/Wood_drying#Shrinkage_and_swelling '''Shrinkage'''] across grain varies dependent upon the orientation of the '''[[Tree Structure|Annular Rings]]''' which themselves tend to shorten and straighten out as wood dries. Also, newer wood will tend to shrink more than older wood so the side of a board nearest to the '''[[Tree Structure|Bark]]''' for example, will shrink more than that towards the tree centre. This has various consequences for the way boards of timber react when dried: | ||

[[File:DefectsLabelled.png|200px|right]] | [[File:DefectsLabelled.png|200px|right]] | ||

* '''Bow''' - this is a curve along the face of a board caused by the wood on one face shrinking more than on the face opposite. | * '''Bow''' - this is a curve along the face of a board caused by the wood on one face shrinking more than on the face opposite. | ||

* '''Crook''' - this is edgewise curving of a board caused by uneven shrinking. | * '''Crook''' - this is edgewise curving of a board caused by uneven shrinking. | ||

* '''Cup''' - 'cupping' is a hollowing of the board throughout its length on its '''[[Tree Structure|Bark]]''' side face: it is for this reason that solid timber window sills, for example, should be positioned 'heart side up'. | * '''Cup''' - 'cupping' is a hollowing of the board throughout its length on its '''[[Tree Structure|Bark]]''' side face: it is for this reason that solid timber window sills, for example, should be positioned 'heart side up' ''(i.e. to ensure condensate does not collect in the middle of the sill)''. | ||

* '''Twist''' - wood grain is rarely perfectly straight and variations in grain direction and shrinkage over the length of a board can result in one end of a board not being in the same plane as the other; it likely to occur more in thin boards than thicker ones and can be tested using '''[[Rules and Straight Edges|Winding Sticks]]'''. | * '''Twist''' - wood grain is rarely perfectly straight and variations in grain direction and shrinkage over the length of a board can result in one end of a board not being in the same plane as the other; it likely to occur more in thin boards than thicker ones and can be tested using '''[[Rules and Straight Edges|Winding Sticks]]'''. | ||

* '''Splits and Checks''' - 'splits' tend to occur at the ends of boards and go through from one side to the other; 'checks' are a partial separation of wood fibres across the '''[[Tree Structure|Annular Rings]]''' . | * '''Splits and Checks''' - 'splits' tend to occur at the ends of boards and go through from one side to the other; 'checks' are a partial separation of wood fibres across the '''[[Tree Structure|Annular Rings]]''' . | ||

---- | |||

<span style="color: green">'''Note:''' | |||

Natural timber continues to swell and shrink as atmospheric conditions and [https://en.wikipedia.org/wiki/Humidity '''Humidity'''] change. Allowances must be made for this expansion and contraction when designing in solid timber if warping, cracking and splitting is to be avoided. | |||

</span> | |||

---- | |||

=====Infestation===== | |||

Commonly referred to as [https://en.wikipedia.org/wiki/Woodworm '''Woodworm'''], timber can be infested with the wood-eating larvae of various species of beetle. '''[[Tree Structure|Sapwood]]''' in particular, and any wood that is in damp and poorly ventilated conditions, is most susceptible to attack. Affected timber can become riddled with small holes to the point where it loses all strength and crumbles. | |||

{| | |||

|- | |||

| [https://en.wikipedia.org/wiki/Common_furniture_beetle '''Common Furniture Beetle'''] ''(Anobium punctatum)'' | |||

| This is the most common wood borer and is responsible for much damage to both furniture and structural timbers. The brown coloured beetles are about 5mm long and lay eggs in joints, cracks and crevices, preferring rough sawn wood or end grain and starting in '''[[Tree Structure|Sapwood]]''' before moving into '''[[Tree Structure|Heartwood]]'''. The larvae hatch and can burrow through the wood for several years to leave a hidden honey-comb wood structure which easily crumbles. | |||

| [[File:FurnitureBeetle.png|100px|right]] | |||

|- | |||

| [https://en.wikipedia.org/wiki/Hylotrupes '''House Longhorn Beetle'''] ''(Hylotrupes bajulus)'' | |||

| Once limited to Europe and still most common in S.E. England, this large beetle has now established itself more generally. Its [https://en.wikipedia.org/wiki/Larva '''Larvae'''] are avid consumers especially of the resin-rich '''[[Tree Structure|Sapwood]]''' of freshly felled '''[[Softwood]]'''. It is a particular danger therefore to the large roof timbers of newly built houses. They are typically black or brown with greyish hair on their upper bodies and their larvae can take up to 10 years to tunnel through the wood leaving an extensive network of holes up to 10mm diameter, which cause almost complete disintegration of sapwood but leave a thin, intact, surface skin which can obscure their presence. | |||

| [[File:HouseLonghornBeetle.png|100px|right]] | |||

|- | |||

| [https://en.wikipedia.org/wiki/Lyctus_brunneus '''Lyctus Beetle'''] ''(Lyctus brunneus)'' | |||

| Also known as the [https://en.wikipedia.org/wiki/Powderpost_beetle '''Powderpost Beetle'''], these mainly infest the starch-rich larged pored '''[[Tree Structure|Sapwood]]''' of comparatively recently '''[[Timber Conversion|Converted]]''' and '''[[Seasoning|Seasoned]]''' timber. Kiln drying does not alter the starch content of timber but after about 15 years starch dries out and has no food value for the larvae. The beetles are about 5mm long with a hood-like head, nocturnal and generally a reddish-brown/black colour. Adults do not live very long but the larvae can spend up to 5 years tunnelling through the timber. | |||

| [[File:LyctusBeetle.png|100px|right]] | |||

|- | |||

| [https://en.wikipedia.org/wiki/Deathwatch_beetle '''Death Watch Beetle'''] ''(Xestobium rufovillosum)'' | |||

| A common borer in the UK and Europe, the [https://en.wikipedia.org/wiki/Deathwatch_beetle '''Death Watch Beetle'''] is a dark greyish-brown in colour and up to 10mm long. It cannot fly and attacks either dead wood or converted timber where fungal attack has already occurred. | |||

| [[File:DeathWatchBeetle.png|100px|right]] | |||

|} | |||

=====Rot===== | |||

Timber kept in moist and poorly ventilated conditions is prone to fungal attack. The [https://en.wikipedia.org/wiki/Wood-decay_fungus '''Fungus'''] lives on the moist wood causing it to decay. Timber kept dry to less than 20% '''[[Seasoning|Moisture Content]]''' is impervious to this form of attack. The terms [https://en.wikipedia.org/wiki/Dry_rot '''Dry Rot'''] and [https://en.wikipedia.org/wiki/Wet_rot '''Wet Rot'''] are in common usage but differentiated only by the type of [https://en.wikipedia.org/wiki/Wood-decay_fungus '''Fungus'''] causing the decay since both require moist conditions to thrive. | |||

[[File:WetRot.jpg|250px|right]] | |||

[https://en.wikipedia.org/wiki/Wet_rot '''Wet Rot'''] is taken to refer to damaged caused by fungal species such as [https://en.wikipedia.org/wiki/Coniophora '''''Coniophora puteana'''''] and thrives where there is a regular source of water because of leaking plumbing for example. It is accompanied by a damp musty smell. It causes affected timber to crack, feel soft and spongy ''(even through a coat of paint)'' and look darker than surrounding timber. Treatment is by stopping the source of moisture, replacing badly damaged timber and treating the surrounding area with a wood hardener and preservative. | |||

[[File:Braunfaeule Holz FI20070208.jpg|250px|right|Braunfaeule Holz FI20070208]] | |||

[https://en.wikipedia.org/wiki/Dry_rot '''Dry Rot'''] is more serious caused by the [https://en.wikipedia.org/wiki/Serpula_lacrymans'''''Serpula lacrymans'''''] wood-destroying fungus. It can thrive in timber with a '''[[Seasoning|Moisture Content]]''' only slightly increased above 20% causing the wood to shrink, darken and crack in a particular ‘cube-like’ manner. The damage is often hidden from view, behind plaster for example, but when active is accompanied by a musty, damp odour and may exhibit fine, cobweb-like greyish strands or cotton wool-like cushions. Treatment is by stopping the source of moisture, replace any damaged timbers and apply fungicide. But [https://en.wikipedia.org/wiki/Dry_rot '''Dry Rot'''] can pass through masonry so it may be necessary to remove plaster and sterilise masonry to ensure it has not spread unseen. | |||

[[Category:Materials and Components]] | [[Category:Materials and Components]] | ||

[[Category:Timber]] | |||

Latest revision as of 07:57, 19 September 2018

Introduction

A Defect is taken to be any irregularity occurring in or on the timber which may lower its strength, durability, utility value or diminish its appearance. Defects may be 'natural' which occur whilst the tree is growing, or 'artificial' as a result of poor conversion, seasoning or handling after felling.

Knots

A most commonly observed defect in timber are Knots. These occur where branches have grown out of the tree trunk. They are more common in some timbers (e.g. Pine) than others. ‘Live Knots’ are fully integrated with the surrounding timber. They may reduce strength and increase difficulty working the timber but are mainly a visual defect - indeed, Knotty Pine is used to decorative effect. ‘Dead Knots’ by contrast are not integrated and often surrounded by Bark and may show signs of decay. They are loose and cannot be relied on to stay in place, often dropping out, leaving a hole which needs to be filled.

Shakes and Checks

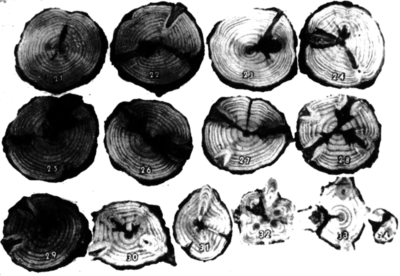

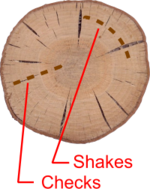

Although the term is often used more widely, a Shake is taken to mean a separation of the Annular Rings (confusingly, this is sometimes referred to as a 'cup shake'). Shakes occur naturally as the tree is growing, especially if in damp conditions. They were once thought to be the result of the tree bending in the wind but research has found that the Clostridium bacterium is the true cause of a Shake.

Checks are a separation of the wood normally occurring across or through the Annular Rings. They are the result of outer layers of wood drying out and shrinking around the still moist inner layers. One reason for Converting timber soon after felling is to minimise this problem.

Shrinkage Defects

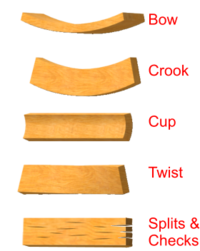

As timber dries out, during Seasoning and afterwards, shrinkage occurs mainly across the Grain with only the slightest movement along the Grain. The amount of Shrinkage across grain varies dependent upon the orientation of the Annular Rings which themselves tend to shorten and straighten out as wood dries. Also, newer wood will tend to shrink more than older wood so the side of a board nearest to the Bark for example, will shrink more than that towards the tree centre. This has various consequences for the way boards of timber react when dried:

- Bow - this is a curve along the face of a board caused by the wood on one face shrinking more than on the face opposite.

- Crook - this is edgewise curving of a board caused by uneven shrinking.

- Cup - 'cupping' is a hollowing of the board throughout its length on its Bark side face: it is for this reason that solid timber window sills, for example, should be positioned 'heart side up' (i.e. to ensure condensate does not collect in the middle of the sill).

- Twist - wood grain is rarely perfectly straight and variations in grain direction and shrinkage over the length of a board can result in one end of a board not being in the same plane as the other; it likely to occur more in thin boards than thicker ones and can be tested using Winding Sticks.

- Splits and Checks - 'splits' tend to occur at the ends of boards and go through from one side to the other; 'checks' are a partial separation of wood fibres across the Annular Rings .

Note: Natural timber continues to swell and shrink as atmospheric conditions and Humidity change. Allowances must be made for this expansion and contraction when designing in solid timber if warping, cracking and splitting is to be avoided.

Infestation

Commonly referred to as Woodworm, timber can be infested with the wood-eating larvae of various species of beetle. Sapwood in particular, and any wood that is in damp and poorly ventilated conditions, is most susceptible to attack. Affected timber can become riddled with small holes to the point where it loses all strength and crumbles.

| Common Furniture Beetle (Anobium punctatum) | This is the most common wood borer and is responsible for much damage to both furniture and structural timbers. The brown coloured beetles are about 5mm long and lay eggs in joints, cracks and crevices, preferring rough sawn wood or end grain and starting in Sapwood before moving into Heartwood. The larvae hatch and can burrow through the wood for several years to leave a hidden honey-comb wood structure which easily crumbles. |  |

| House Longhorn Beetle (Hylotrupes bajulus) | Once limited to Europe and still most common in S.E. England, this large beetle has now established itself more generally. Its Larvae are avid consumers especially of the resin-rich Sapwood of freshly felled Softwood. It is a particular danger therefore to the large roof timbers of newly built houses. They are typically black or brown with greyish hair on their upper bodies and their larvae can take up to 10 years to tunnel through the wood leaving an extensive network of holes up to 10mm diameter, which cause almost complete disintegration of sapwood but leave a thin, intact, surface skin which can obscure their presence. |  |

| Lyctus Beetle (Lyctus brunneus) | Also known as the Powderpost Beetle, these mainly infest the starch-rich larged pored Sapwood of comparatively recently Converted and Seasoned timber. Kiln drying does not alter the starch content of timber but after about 15 years starch dries out and has no food value for the larvae. The beetles are about 5mm long with a hood-like head, nocturnal and generally a reddish-brown/black colour. Adults do not live very long but the larvae can spend up to 5 years tunnelling through the timber. | |

| Death Watch Beetle (Xestobium rufovillosum) | A common borer in the UK and Europe, the Death Watch Beetle is a dark greyish-brown in colour and up to 10mm long. It cannot fly and attacks either dead wood or converted timber where fungal attack has already occurred. |  |

Rot

Timber kept in moist and poorly ventilated conditions is prone to fungal attack. The Fungus lives on the moist wood causing it to decay. Timber kept dry to less than 20% Moisture Content is impervious to this form of attack. The terms Dry Rot and Wet Rot are in common usage but differentiated only by the type of Fungus causing the decay since both require moist conditions to thrive.

Wet Rot is taken to refer to damaged caused by fungal species such as Coniophora puteana and thrives where there is a regular source of water because of leaking plumbing for example. It is accompanied by a damp musty smell. It causes affected timber to crack, feel soft and spongy (even through a coat of paint) and look darker than surrounding timber. Treatment is by stopping the source of moisture, replacing badly damaged timber and treating the surrounding area with a wood hardener and preservative.

Dry Rot is more serious caused by the Serpula lacrymans wood-destroying fungus. It can thrive in timber with a Moisture Content only slightly increased above 20% causing the wood to shrink, darken and crack in a particular ‘cube-like’ manner. The damage is often hidden from view, behind plaster for example, but when active is accompanied by a musty, damp odour and may exhibit fine, cobweb-like greyish strands or cotton wool-like cushions. Treatment is by stopping the source of moisture, replace any damaged timbers and apply fungicide. But Dry Rot can pass through masonry so it may be necessary to remove plaster and sterilise masonry to ensure it has not spread unseen.