Hand Drill: Difference between revisions

From DT Online

(Created Article) |

m (Added link) |

||

| Line 6: | Line 6: | ||

Most have a [https://en.wikipedia.org/wiki/Chuck_%28engineering%29 '''Keyed Chuck'''] with a capacity of up to 6mm diameter. The handle turns a large '''[[:Category:Gears|Bevel Gear]]''' which meshes with one or two smaller '''[[:Category:Gears|Pinions]]'''. The '''[[Gear Ratio]]''' provides the neccessary '''[[Mechanical Advantage]]'''. | Most have a [https://en.wikipedia.org/wiki/Chuck_%28engineering%29 '''Keyed Chuck'''] which accept [https://en.wikipedia.org/wiki/Drill_bit_shank#Straight_shank '''Parallel Shank'''] drills with a capacity of up to 6mm diameter. The handle turns a large '''[[:Category:Gears|Bevel Gear]]''' which meshes with one or two smaller '''[[:Category:Gears|Pinions]]'''. The '''[[Gear Ratio]]''' provides the neccessary '''[[Mechanical Advantage]]'''. | ||

Revision as of 08:09, 28 October 2015

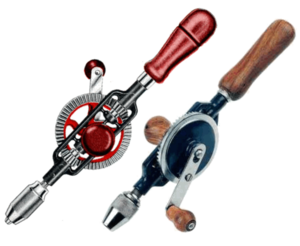

Hand Drills (aka Wheel Brace) are a useful addition to a toolbox and can complement Electric Drills when there is a need to:

- drill just a few small holes

- drill pilot holes

- countersink holes

Most have a Keyed Chuck which accept Parallel Shank drills with a capacity of up to 6mm diameter. The handle turns a large Bevel Gear which meshes with one or two smaller Pinions. The Gear Ratio provides the neccessary Mechanical Advantage.

The better quality drills always have two Pinions and the Gears are fully enclosed to avoid the danger of trapped fingers!