Glass and Ceramic Drills: Difference between revisions

From DT Online

mNo edit summary |

mNo edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:GlassCeramicDrills.png|300px|right | [[File:GlassCeramicDrills.png|300px|right|link=http://www.amazon.co.uk/gp/product/B00VR9DJRO/ref=as_li_tl?ie=UTF8&camp=1634&creative=6738&creativeASIN=B00VR9DJRO&linkCode=as2&tag=dton06-21]] | ||

__TOC__ | |||

=====Description===== | |||

Drilling either '''Glass''' or '''Ceramic''' is quite possible but these are '''[[Hardness|Hard]]''', '''[[Brittleness|Brittle]]''' materials and great care needs to be taken. Small diameter bits with [https://en.wikipedia.org/wiki/Tungsten_carbide '''Tungsten Carbide'''] [https://en.wikipedia.org/wiki/Drill_bit#Glass_drill_bits '''Spade Bits'''] can be used to drill ceramic tiles quite easily, but for larger diameters and for drilling glass, diamond drill bits are preferred. | |||

=====Features and Applications===== | |||

The key to success is to use a '''[[Portable Electric Drills|Cordless Power Drill]]''' at slow speed ''(and without any Hammer Action!)'' and not to try and force the drill through ''(i.e. take time)''. Do not try to drill a hole too near the edge ''(e.g. stay at least 20mm away)'' and mark the centre with adhesive tape to provide a location for the drill point to stop it slipping around at the start. | The key to success is to use a '''[[Portable Electric Drills|Cordless Power Drill]]''' at slow speed ''(and without any Hammer Action!)'' and not to try and force the drill through ''(i.e. take time)''. Do not try to drill a hole too near the edge ''(e.g. stay at least 20mm away)'' and mark the centre with adhesive tape to provide a location for the drill point to stop it slipping around at the start. | ||

| Line 7: | Line 14: | ||

Most importantly, ensure there is a constant supply of water as a coolant ''(hence the recommendation to use a '''cordless''' drill)''. This can be done by building a [https://en.wikipedia.org/wiki/Putty putty] or [https://en.wikipedia.org/wiki/Putty Plasticine] reservoir around the drill bit or preferably, immersing the whole work-piece in a shallow tray of water, ensuring it is well supported with a rubber pad, '''[[Manufactured Board|Ply]]''' or '''[[Manufactured Board|MDF]]''' for example, underneath it ''('''this is a strongly recommended when drilling glass''' since the surrounding water prevents cracks propagating, which would shatter the glass)''. The most critical point is when the drill is about to break through, so ease off pressure and ideally have the work-piece clamped or held in some way such that the drill cannot ''grab''. | Most importantly, ensure there is a constant supply of water as a coolant ''(hence the recommendation to use a '''cordless''' drill)''. This can be done by building a [https://en.wikipedia.org/wiki/Putty putty] or [https://en.wikipedia.org/wiki/Putty Plasticine] reservoir around the drill bit or preferably, immersing the whole work-piece in a shallow tray of water, ensuring it is well supported with a rubber pad, '''[[Manufactured Board|Ply]]''' or '''[[Manufactured Board|MDF]]''' for example, underneath it ''('''this is a strongly recommended when drilling glass''' since the surrounding water prevents cracks propagating, which would shatter the glass)''. The most critical point is when the drill is about to break through, so ease off pressure and ideally have the work-piece clamped or held in some way such that the drill cannot ''grab''. | ||

---- | ---- | ||

<span style="color: red">'''Safety Point!''' | <span style="color: red">'''Safety Point!''' | ||

Latest revision as of 18:52, 11 March 2017

Description

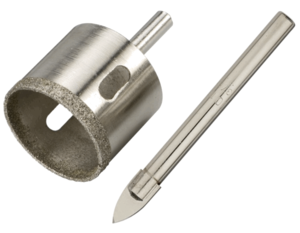

Drilling either Glass or Ceramic is quite possible but these are Hard, Brittle materials and great care needs to be taken. Small diameter bits with Tungsten Carbide Spade Bits can be used to drill ceramic tiles quite easily, but for larger diameters and for drilling glass, diamond drill bits are preferred.

Features and Applications

The key to success is to use a Cordless Power Drill at slow speed (and without any Hammer Action!) and not to try and force the drill through (i.e. take time). Do not try to drill a hole too near the edge (e.g. stay at least 20mm away) and mark the centre with adhesive tape to provide a location for the drill point to stop it slipping around at the start.

Most importantly, ensure there is a constant supply of water as a coolant (hence the recommendation to use a cordless drill). This can be done by building a putty or Plasticine reservoir around the drill bit or preferably, immersing the whole work-piece in a shallow tray of water, ensuring it is well supported with a rubber pad, Ply or MDF for example, underneath it (this is a strongly recommended when drilling glass since the surrounding water prevents cracks propagating, which would shatter the glass). The most critical point is when the drill is about to break through, so ease off pressure and ideally have the work-piece clamped or held in some way such that the drill cannot grab.

Safety Point! Ceramics, and especially Glass, are extremely brittle materials and prone to splintering, shattering or cracking. Do not attempt any drilling operations without hand and eye protection and ensure the workpiece is held firmly. Also, do not use mains electric equipment near water.