Scarf Joint: Difference between revisions

From DT Online

mNo edit summary |

Added Template |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

=====Description===== | |||

[https://en.wikipedia.org/wiki/Scarf_joint '''Scarf Joints'''] are '''Lengthening Joints''' used to join pieces of timber end to end. Timber often has to be lengthened in big projects such as garages, carports or floor renovation and, occasionally, it may be necessary to insert a length of timber when repairing or restoring furniture. | [https://en.wikipedia.org/wiki/Scarf_joint '''Scarf Joints'''] are '''Lengthening Joints''' used to join pieces of timber end to end. Timber often has to be lengthened in big projects such as garages, carports or floor renovation and, occasionally, it may be necessary to insert a length of timber when repairing or restoring furniture. | ||

When compared with the timbers they are joining, most '''Scarf Joints''' are weak and when used in construction often need strengthening by bolting additional '''Fish Plates''' on either side or fixing metal straps around them. Also, if timbers have to be joined to make a garden [https://en.wikipedia.org/wiki/Pergola '''Pergola'''] for example, it is good practice to make the joint over a supporting pillar. | When compared with the timbers they are joining, most '''Scarf Joints''' are weak and when used in construction often need strengthening by bolting additional '''Fish Plates''' on either side or fixing metal straps around them. Also, if timbers have to be joined to make a garden [https://en.wikipedia.org/wiki/Pergola '''Pergola'''] for example, it is good practice to make the joint over a supporting pillar. | ||

---- | |||

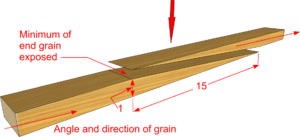

<span style="color: green">[[File:15to1ScarfJoint.png|300px|right]]'''Note:'''</span> | |||

<span style="color: green">In situations where neither of these strengthening solutions is achievable, maximum strength is obtained by ensuring that the '''Scarf Joint''' angle is no steeper than 1 in 15 and is cut along the line of the grain to minimise the amount of end grain appearing on the angled surface.</span> | |||

---- | |||

=====Scarf Joint Variations===== | |||

* '''Plain Scarf''' | * '''Plain Scarf''' | ||

| Line 42: | Line 48: | ||

[[File:TaperedFingerWidening.png|300px|right]] | [[File:TaperedFingerWidening.png|300px|right]] | ||

Modern practice, arising from the need to preserve timber resources and made possible by modern tooling and adhesives, is to use '''[[Comb Joint|Tapered Finger Joints]]''' extensively to join random lengths of timber stock together and to further combine these strips into wide boards ''(e.g. for table tops)''. | Modern practice, arising from the need to preserve timber resources and made possible by modern tooling and adhesives, is to use '''[[Comb Joint|Tapered Finger Joints]]''' extensively to join random lengths of timber stock together and to further combine these strips into wide boards ''(e.g. for table tops)''. | ||

{{Wood Joints Buyers Guide}} | |||

[[Category:Wood Joints]] | [[Category:Wood Joints]] | ||

Latest revision as of 16:15, 4 June 2016

Description

Scarf Joints are Lengthening Joints used to join pieces of timber end to end. Timber often has to be lengthened in big projects such as garages, carports or floor renovation and, occasionally, it may be necessary to insert a length of timber when repairing or restoring furniture.

When compared with the timbers they are joining, most Scarf Joints are weak and when used in construction often need strengthening by bolting additional Fish Plates on either side or fixing metal straps around them. Also, if timbers have to be joined to make a garden Pergola for example, it is good practice to make the joint over a supporting pillar.

In situations where neither of these strengthening solutions is achievable, maximum strength is obtained by ensuring that the Scarf Joint angle is no steeper than 1 in 15 and is cut along the line of the grain to minimise the amount of end grain appearing on the angled surface.

Scarf Joint Variations

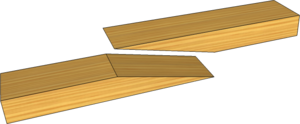

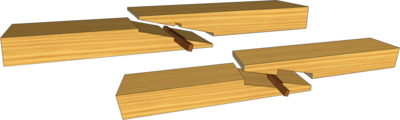

- Plain Scarf

The joining pieces are simply cut to a shallow angle and glued together. It is a weak joint, suitable only for repair and patching work in furniture, but if care is taken to match the grain, the finished repair will be hardly noticeable.

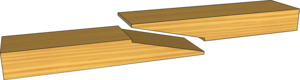

- Scarf with Nibs

If small shoulders or Nibs are added these provide a positive stop at the end of the joint. This may improve performance in Compression but will not improve Bending Strength and if exposed to such, the joint would need additional reinforcement.

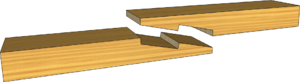

- Hooked Scarf with Nibs

To improve performance in Tension, Hooks can be added as shown but, again, if exposed to Bending, the joint would need additional reinforcement.

- Keylocked Hooked Scarf with Nibs

Keys or Wedges can be added to tighten joints (with or without Hooks) on assembly and will stop the joints loosening, but they do not add greatly to their strength.

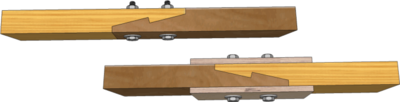

- Scarf Joint Reinforcement

Scarf Joints may be Nailed, Screwed, or Bolted through but the addition of Fish Plates may be required for extra strength.

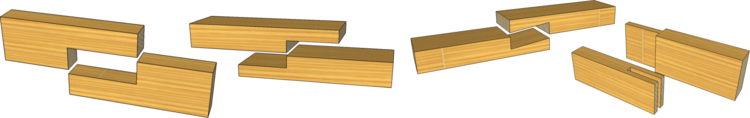

Variations of several standard wood joints can also be used as Lengthening Joints in a Scarf Joint configuration (e.g. Halving Joint, Dovetail Joint, Bridle Joint) as shown).

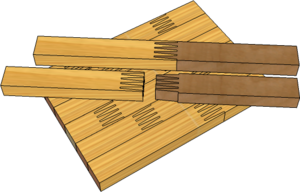

Modern practice, arising from the need to preserve timber resources and made possible by modern tooling and adhesives, is to use Tapered Finger Joints extensively to join random lengths of timber stock together and to further combine these strips into wide boards (e.g. for table tops).

- Good tools will last a lifetime - buy the best you can afford!