Nails and Pins: Difference between revisions

From DT Online

m Corrected Link |

mNo edit summary |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:DovetailNailingPunching.png | | [[File:DovetailNailingPunching.png |300px|right]] | ||

__TOC__ | |||

=====Description===== | |||

The holding power of [https://en.wikipedia.org/wiki/Nail_%28fastener%29 '''Nails'''] depends upon [https://en.wikipedia.org/wiki/Friction '''Friction'''] and some nails have coatings or grips designed into the body of the nail ''(i.e. shank)'' to improve this. In addition, some coatings are applied to improve resistance to corrosion ''(e.g. [https://en.wikipedia.org/wiki/Galvanization '''Galvanising''']).'' Nails may be driven in at opposing angles as shown. This is a process known as '''Dovetail Nailing''' and improves their holding power. | The holding power of [https://en.wikipedia.org/wiki/Nail_%28fastener%29 '''Nails'''] depends upon [https://en.wikipedia.org/wiki/Friction '''Friction'''] and some nails have coatings or grips designed into the body of the nail ''(i.e. shank)'' to improve this. In addition, some coatings are applied to improve resistance to corrosion ''(e.g. [https://en.wikipedia.org/wiki/Galvanization '''Galvanising''']).'' Nails may be driven in at opposing angles as shown. This is a process known as '''Dovetail Nailing''' and improves their holding power. | ||

Also shown opposite is the use of a '''[[Punches|Nail Punch]]'''. It is good practice on fine work to drive nails in to a few | Also shown opposite is the use of a '''[[:Category:Punches|Nail Punch]]'''. It is good practice on fine work to drive nails in to a few millimetres of the surface then punch them below it. This will avoid any damage to a [[Planes|plane iron]], for example, when cleaning up the work after assembly. The punched hole can then be filled with [https://en.wikipedia.org/wiki/Wood_putty '''Wood Filler'''] to prepare for final finishing and to avoid any rust stains appearing on the surface. | ||

When using nails in softwoods they can usually be driven in directly but for hardwoods, and sometimes to avoid splitting near the end on any timbers, a small hole may be drilled in the top piece first - or bored with a '''[[Awl and Bradawl|Bradawl]]'''. | When using nails in softwoods they can usually be driven in directly but for hardwoods, and sometimes to avoid splitting near the end on any timbers, a small hole may be drilled in the top piece first - or bored with a '''[[Awl and Bradawl|Bradawl]]'''. Alternatively, the head of a nail may be cut off and the nail itself used as a drill - the snipped off end acting similarly to a mini '''[[Flat Bit]]'''. | ||

| Line 20: | Line 23: | ||

</span> | </span> | ||

---- | ---- | ||

=====Types and Applications===== | |||

{| | {| | ||

|- | |- | ||

| Line 46: | Line 52: | ||

| these have ridges around the shank to provide extra grip. | | these have ridges around the shank to provide extra grip. | ||

| [[File:RingNails.png|100px|right]] | | [[File:RingNails.png|100px|right]] | ||

|} | |||

{{Nails and Pins Buyers Guide (1)}} | |||

=====Specialised Fastenings===== | |||

{| | |||

|- | |- | ||

| '''Corrugated Fasteners''' ''(aka Wiggle Nail)'' | | '''Corrugated Fasteners''' ''(aka Wiggle Nail)'' | ||

| Line 82: | Line 95: | ||

{{Nails and Pins Buyers Guide (2)}} | |||

[[Category:Fixings and Fastenings]] | [[Category:Fixings and Fastenings]] | ||

Latest revision as of 08:18, 27 July 2018

Description

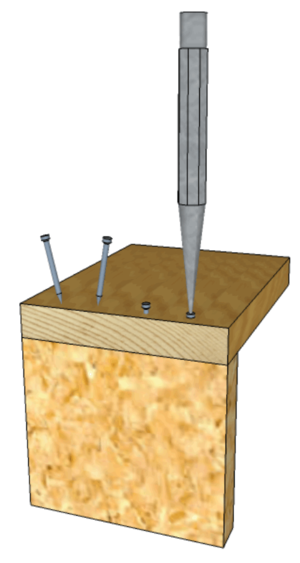

The holding power of Nails depends upon Friction and some nails have coatings or grips designed into the body of the nail (i.e. shank) to improve this. In addition, some coatings are applied to improve resistance to corrosion (e.g. Galvanising). Nails may be driven in at opposing angles as shown. This is a process known as Dovetail Nailing and improves their holding power.

Also shown opposite is the use of a Nail Punch. It is good practice on fine work to drive nails in to a few millimetres of the surface then punch them below it. This will avoid any damage to a plane iron, for example, when cleaning up the work after assembly. The punched hole can then be filled with Wood Filler to prepare for final finishing and to avoid any rust stains appearing on the surface.

When using nails in softwoods they can usually be driven in directly but for hardwoods, and sometimes to avoid splitting near the end on any timbers, a small hole may be drilled in the top piece first - or bored with a Bradawl. Alternatively, the head of a nail may be cut off and the nail itself used as a drill - the snipped off end acting similarly to a mini Flat Bit.

Most Nails are made from cold drawn mild steel wire. This process improves the strength or wire by work hardening such that Nails can be driven into timber by use of Hammers. If nails do become bent they can easily be withdrawn using Pincers or a Claw Hammer for example.

Note: Nails often bend whilst being driven in because the hammer head is not kept clean and polished by regular rubbing it on a piece of fine Glasspaper.

Safety Point! Builders may also use Nail Guns but these are extremely dangerous and not suitable for school use.

Types and Applications

| Round Wire Nails | Used for general carpentry where the presence of the round steel head would be acceptable (e.g. packing case construction and soft timber framing) |  |

| Oval Wire Nails | These enter the wood cleanly with less tendency to cause splitting and are used as finishing nails for most joinery work.

Note: When driving in a number of nails close together, avoid positioning them in line with the grain but stagger them to help avoid splitting. |

|

| Panel Pins | Use for fine cabinet work, these are thin nails with an inverted cone-shaped head which enters the wood cleanly. (Shown in the background is a Push Pin Tool which can be used to hold small panel pins magnetically and then push them into the material. instead of using a hammer) |  |

| Deep Drive Panel Pins | Panel Pins which have a double cone-shaped head resulting in a pointed top such that the last blow drives them below the surface. |  |

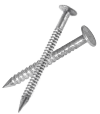

| Ring Nails | these have ridges around the shank to provide extra grip. |  |

|

|

|

|

|

|

|

|

|

| Round Wire Nails |

Oval Wire Nails |

Panel Pins |

Clout Nails |

Ring Nails |

Upholstery Tacks |

Masonry Nails |

Fencing Staples |

Corrugated Fasteners |

Specialised Fastenings

| Corrugated Fasteners (aka Wiggle Nail) | used to strengthen edge to edge joints (e.g. as in the sides of packing cases) or holding together the framed core of cheap ply-skinned panels. |  |

| Tacks | used to secure thin materials and fabrics to wood (e.g. carpets to floorboards). |  |

| Upholstery Tacks | usually made with a large dome-shaped brass or black-japanned head to form a decorative feature in some forms of upholstery work. |  |

| Clout Nails | usually galvanised and with a large round head, these are used mainly for holding down roofing felt. |  |

| Floor Brad | rectangular in cross section and stamped from flat sheet, these are used mainly for fixing floorboards to joists. |  |

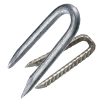

| Fencing Staples | a small U-shaped nail, often galvanised and commonly used for fixing fence wire to posts. |  |

| Masonry Nails | a hardened stout nail designed to be driven directly into concrete blocks or cement for example. Use a heavier hammer and hit the nail square on the head since, rather than bend, they may break if not driven in straight.

Safety Point! Masonry nails are brittle and break easily if not driven in straight, so it is important to wear eye protection to guard against flying pieces |

|

|

|

|

|

|

|

|

|

|

| Round Wire Nails |

Oval Wire Nails |

Panel Pins |

Clout Nails |

Ring Nails |

Upholstery Tacks |

Masonry Nails |

Fencing Staples |

Corrugated Fasteners |