Fusee: Difference between revisions

From DT Online

(Added Template) |

mNo edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 15: | Line 15: | ||

Cone shaped pulleys are sometimes also used in [https://en.wikipedia.org/wiki/Potter%27s_wheel Potters' Wheels] to create a variable speed drive. | Cone shaped pulleys are sometimes also used in [https://en.wikipedia.org/wiki/Potter%27s_wheel Potters' Wheels] to create a variable speed drive. | ||

=====Animations===== | |||

* Examples from '''[[2100 Animated Mechanical Mechanisms|Nguyen Duc Thang's]]''' YouTube Channel '''[[2100 Animated Mechanical Mechanisms]]''' | |||

{| | |||

|- | |||

| [https://youtu.be/cFTMUfRsHUc '''Variable Cone Drive'''] - the input and output shafts are parallel and the output velocity is varied by moving the drive belt. | |||

| {{#ev:youtube|cFTMUfRsHUc|200x200|right||frame|loop=1&autoplay=0&playlist=cFTMUfRsHUc}} | |||

| [https://youtu.be/lorIO9hJ960 '''Variable Cone and Disc Drive'''] - the drive is transmitted from the top disc to the one below via a double cone roller which can be positioned to vary the output velocity. | |||

| {{#ev:youtube|lorIO9hJ960|200x200|right||frame|loop=1&autoplay=0&playlist=lorIO9hJ960}} | |||

|} | |||

{{Basic Machines Buyers Guide}} | {{Basic Machines Buyers Guide}} | ||

Latest revision as of 14:00, 28 August 2016

Description

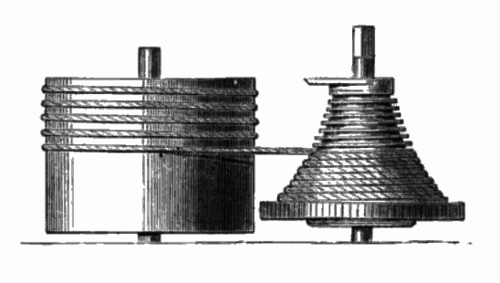

The Fusee was invented to compensate for the reducing turning power (or Torque) of a clockwork spring as it winds down.

Features and Applications

The Fusee is essentially a conical pulley and the drive is transferred progressively from a large diameter Driver to a smaller diameter Driver with a consequent increase in Mechanical Advantage.

Cone shaped pulleys are sometimes also used in Potters' Wheels to create a variable speed drive.

Animations

- Examples from Nguyen Duc Thang's YouTube Channel 2100 Animated Mechanical Mechanisms

| Variable Cone Drive - the input and output shafts are parallel and the output velocity is varied by moving the drive belt. | Variable Cone and Disc Drive - the drive is transmitted from the top disc to the one below via a double cone roller which can be positioned to vary the output velocity. |