Thermoforming Plastics: Difference between revisions

From DT Online

Added text |

mNo edit summary |

||

| (13 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:VacuformVisualization.gif| | [[File:VacuformVisualization.gif|400px|right|VacuformVisualization|link=https://commons.wikimedia.org/wiki/File:VacuformVisualization.gif]] | ||

__TOC__ | __TOC__ | ||

=====Description===== | =====Description===== | ||

The term [https://en.wikipedia.org/wiki/Thermoforming '''Thermoforming'''] could be taken literally to include any process which uses heat to create a 3D form - '''[[:Category:Blacksmithing|Blacksmithing]]''' for example. | The term [https://en.wikipedia.org/wiki/Thermoforming '''Thermoforming'''] could be taken literally to include any process which uses heat to create a 3D form - '''[[:Category:Blacksmithing|Blacksmithing]]''' for example. | ||

'''DT Online''' includes as [https://en.wikipedia.org/wiki/Thermoforming '''Thermoforming'''] all processes in which [https://en.wikipedia.org/wiki/Thermoplastic '''Thermoplastics'''] are heated to create products with a particular emphasis on methods of moulding flat sheet materials. | '''DT Online''' includes as [https://en.wikipedia.org/wiki/Thermoforming '''Thermoforming'''] all processes in which [https://en.wikipedia.org/wiki/Thermoplastic '''Thermoplastics'''] are heated to create products with a particular emphasis on methods of moulding flat sheet materials. | ||

| Line 24: | Line 14: | ||

=====Press Moulding===== | =====Press Moulding===== | ||

The sheet of Acrylic can be heated in | The sheet of Acrylic can be heated in the plastics oven set at between 135<sup><small>0</small></sup>C to 175<sup><small>0</small></sup>C ''(275°F to 350°F)'' then placed over a mould shape and pressed into it as shown - the two parts of the mould should be made with an allowance between them to accommodate the thickness of plastics sheet used. | ||

| Line 30: | Line 20: | ||

Small pieces can be heated by careful use of a '''Hot Air Gun''' which is continuously moved over the surface until the Acrylic becomes suitably '''[[Malleability|Malleable]]'''. | Small pieces can be heated by careful use of a '''Hot Air Gun''' which is continuously moved over the surface until the Acrylic becomes suitably '''[[Malleability|Malleable]]''' - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting. | ||

| Line 37: | Line 27: | ||

=====Drape Moulding===== | =====Drape Moulding===== | ||

The sheet of Acrylic can be heated in | The sheet of Acrylic can be heated in the plastics oven as above or small pieces heated with a '''Hot Air Gun''' - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting. | ||

| Line 59: | Line 49: | ||

<div style="clear: both;"></div> | <div style="clear: both;"></div> | ||

=====Line Bending===== | =====Line Bending===== | ||

As the name implies, a '''[[Line Bending|Strip Heater]]''' is a heating source which is shielded in such a way that only a narrow strip is exposed. In modern '''[[Line Bending|Strip Heaters]]''' the heat source is usually a length of [https://en.wikipedia.org/wiki/Nichrome '''Nichrome Wire'''] but older machines may use a [https://en.wikipedia.org/wiki/Infrared_heater '''Infra-red Element''']. | |||

[[File:StripHeater.png|600px|center]] | [[File:StripHeater.png|600px|center]] | ||

A sheet of Acrylic, or similar, can be marked out using a '''[[Pens and Pencils|Felt-Tip Pen]]''' and the bend or fold line laid across the heating strip untill it softens enough to bend easily by hand to the required angle. Materials thicker than 3mm should be turned regularly to avoid blistering caused by over-heating on one side - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting. | |||

Complex products may be modelled in card first to check which order to complete the bends or folds. '''[[Jig|Bending Jigs]]''' can be made to ensure folds are completed accurately and held in position until the material cools. | |||

| Line 67: | Line 66: | ||

=====Vacuum Forming===== | =====Vacuum Forming===== | ||

[https://en.wikipedia.org/wiki/Vacuum_forming '''Vacuum Forming'''] is a process in which a sheet of relatively thin '''[[Plastics|Thermoplastics]]''' ''(e.g. 1mm to 3mm thick)'' is heated, stretched over a mould and then sucked down on to it by a vacuum. | |||

The mould can be made by any material which will withstand the heat of the plastics and the force of the vacuum ''(e.g. wood or plaster)''. Moulds should be created such that any vertical surfaces have a slight taper or '''''draft''''' to ensure they can be withdrawn after moulding. They should be well finished and brushing on '''Talcum Powder''' or using '''Silicone Spray''' will aid their release ''(use only if the inside of the finished moulding is not to be painted - paint does not stick to silicone!)''. Moulds which have recesses should be made hollow with bleed holes drilled into them to help the vacuum draw the plastics in. | |||

=====Acrylic 'Memory'===== | |||

'''[[Plastics|Thermoplastics]]''' such as [https://en.wikipedia.org/wiki/Poly(methyl_methacrylate) '''Acrylic'''] can easy be bent and formed when heated to approximately 150<sup><small>0</small></sup>C but will return to their original state when re-heated. This phenomenom is sometimes referred to as the plastics ‘Memory’. The process can be used to produce Acrylic jewellery, light fittings and embossed name stamps for example. | |||

---- | |||

<span style="color: blue">'''Activity:''' | |||

Place an empty Potato Crisp packet inside the plastics oven ''(or heat using a Heat Gun)'' and observe what happens. What does this tell you about how the pack was manufactured? | |||

</span> | |||

---- | |||

{| | |||

|- | |||

| To create a raised design on Acrylic for example, start by forming a pattern, using any materials that will withstand the eventual heat and pressure ''(e.g. wire, ‘found’ objects such as washers, nails etc., steel strip or sheet which has been shaped as needed - or simply cut out of MDF for example)'', | |||

| width=30%|[[File:MemoryStamp7.png|300px|right]] | |||

|- | |||

| Heat a block of Acrylic in the plastics oven set between 275°F to 350°F ''(135<sup><small>0</small></sup>C to 175<sup><small>0</small></sup>C)'' - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting. | |||

Place the pattern on to the heated plastics, sandwich between scrap MDF or similar and squeeze together until cool ''(e.g. using a '''[[Engineers Vice|Vice]]''' or '''[[G Cramp]]''')''. When released, an imprint of the pattern will be left in the surface of the Acrylic. | |||

| [[File:MemoryStamp8.png|300px|right]] | |||

|- | |||

| Sand, file or machine the Acrylic block back to a flat surface. Choose at this stage whether to polish the whole surface or to leave frosted with the option of polishing only the raised surface later. | |||

Place the Acrylic block back into the plastics oven and reheat. The block will attempt to return to its original size except for, of course, the material which was removed previously, to leave the finished indented design. | |||

| [[File:MemoryStamp9.png|300px|right]] | |||

|} | |||

---- | |||

<span style="color: red">'''Safety Point!''' | |||

* <span style="color: red">Heating plastics may generate fumes so always ensure good ventilation or extraction and avoid inhalation. | |||

* <span style="color: red">Always use a separate plastics oven and do no use it afterwards for heating food. | |||

* <span style="color: red">Plastics such as ‘Perspex’ are very '''[[Brittleness|Brittle]]''' materials so wear eye protection when cutting and shaping them. | |||

* <span style="color: red">Wear gloves when handling hot plastics | |||

</span> | |||

---- | |||

{{Thermoforming Buyers Guide}} | |||

[[Category:Skills and Processes]] | [[Category:Skills and Processes]] | ||

[[Category:Working Plastics]] | |||

Latest revision as of 17:19, 8 December 2016

Description

The term Thermoforming could be taken literally to include any process which uses heat to create a 3D form - Blacksmithing for example.

DT Online includes as Thermoforming all processes in which Thermoplastics are heated to create products with a particular emphasis on methods of moulding flat sheet materials.

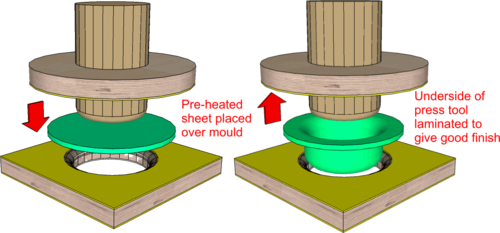

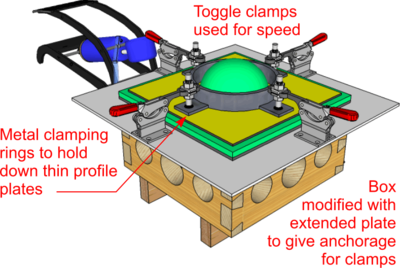

Press Moulding

The sheet of Acrylic can be heated in the plastics oven set at between 1350C to 1750C (275°F to 350°F) then placed over a mould shape and pressed into it as shown - the two parts of the mould should be made with an allowance between them to accommodate the thickness of plastics sheet used.

Moulding plates can be Laminated with ‘Formica’ or similar and have well rounded corners to ensure the surface finish of the Acrylic is not unduly marked as pressure is applied.

Small pieces can be heated by careful use of a Hot Air Gun which is continuously moved over the surface until the Acrylic becomes suitably Malleable - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting.

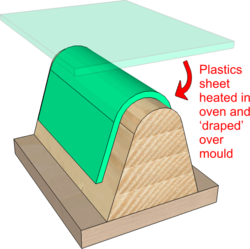

Drape Moulding

The sheet of Acrylic can be heated in the plastics oven as above or small pieces heated with a Hot Air Gun - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting.

Use oven gloves or similar when handling the hot Acrylic sheet and simply ‘drape’ it over a pre-prepared mould.

Minor adjustments can be made throughout using a Hot Air Gun to maintain moulding temperature and an extended moulding time can be achieved if the mould is first pre-heated.

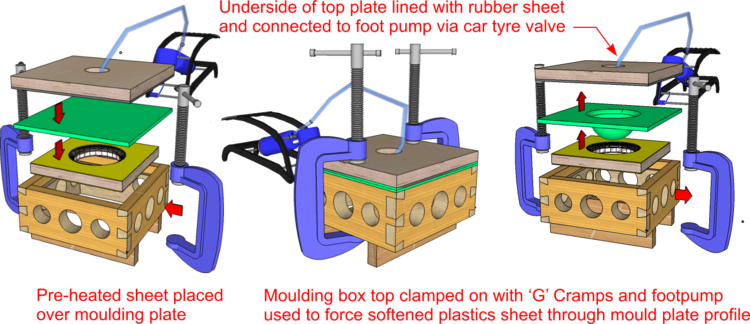

Blow Moulding

Line Bending

As the name implies, a Strip Heater is a heating source which is shielded in such a way that only a narrow strip is exposed. In modern Strip Heaters the heat source is usually a length of Nichrome Wire but older machines may use a Infra-red Element.

A sheet of Acrylic, or similar, can be marked out using a Felt-Tip Pen and the bend or fold line laid across the heating strip untill it softens enough to bend easily by hand to the required angle. Materials thicker than 3mm should be turned regularly to avoid blistering caused by over-heating on one side - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting.

Complex products may be modelled in card first to check which order to complete the bends or folds. Bending Jigs can be made to ensure folds are completed accurately and held in position until the material cools.

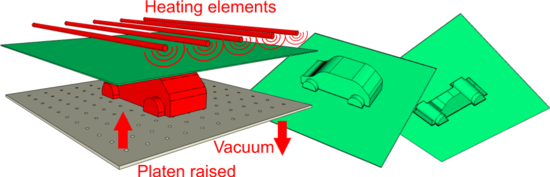

Vacuum Forming

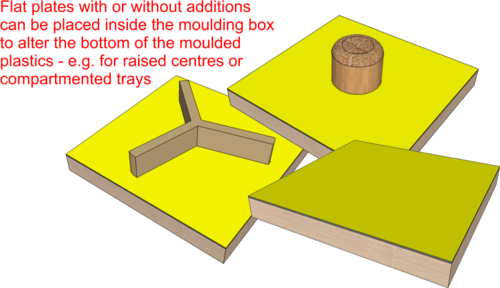

Vacuum Forming is a process in which a sheet of relatively thin Thermoplastics (e.g. 1mm to 3mm thick) is heated, stretched over a mould and then sucked down on to it by a vacuum.

The mould can be made by any material which will withstand the heat of the plastics and the force of the vacuum (e.g. wood or plaster). Moulds should be created such that any vertical surfaces have a slight taper or draft to ensure they can be withdrawn after moulding. They should be well finished and brushing on Talcum Powder or using Silicone Spray will aid their release (use only if the inside of the finished moulding is not to be painted - paint does not stick to silicone!). Moulds which have recesses should be made hollow with bleed holes drilled into them to help the vacuum draw the plastics in.

Acrylic 'Memory'

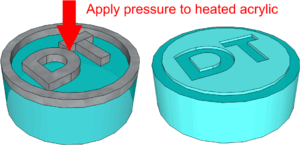

Thermoplastics such as Acrylic can easy be bent and formed when heated to approximately 1500C but will return to their original state when re-heated. This phenomenom is sometimes referred to as the plastics ‘Memory’. The process can be used to produce Acrylic jewellery, light fittings and embossed name stamps for example.

Activity: Place an empty Potato Crisp packet inside the plastics oven (or heat using a Heat Gun) and observe what happens. What does this tell you about how the pack was manufactured?

| To create a raised design on Acrylic for example, start by forming a pattern, using any materials that will withstand the eventual heat and pressure (e.g. wire, ‘found’ objects such as washers, nails etc., steel strip or sheet which has been shaped as needed - or simply cut out of MDF for example), |  |

| Heat a block of Acrylic in the plastics oven set between 275°F to 350°F (1350C to 1750C) - experiment to find the right temperature and be careful not to overheat the plastics : this will cause bubbling and eventual melting.

|

|

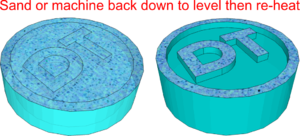

| Sand, file or machine the Acrylic block back to a flat surface. Choose at this stage whether to polish the whole surface or to leave frosted with the option of polishing only the raised surface later.

|

|

Safety Point!

- Heating plastics may generate fumes so always ensure good ventilation or extraction and avoid inhalation.

- Always use a separate plastics oven and do no use it afterwards for heating food.

- Plastics such as ‘Perspex’ are very Brittle materials so wear eye protection when cutting and shaping them.

- Wear gloves when handling hot plastics