Design, Make and Test a Warren Girder: Difference between revisions

From DT Online

Created article |

m Added links |

||

| Line 1: | Line 1: | ||

==== What to Make: ==== | ==== What to Make: ==== | ||

Design Make and Test a Warren Girder | Design Make and Test a [https://en.wikipedia.org/wiki/Girder '''Warren Girder'''] truss frame 450mm wide to span a 400mm wide gap and support a centrally applied load of 1kg | ||

| Line 10: | Line 10: | ||

====What to Use:==== | ====What to Use:==== | ||

* Material available is restricted to 3mm thick medium density Balsa Wood. | * Material available is restricted to 3mm thick medium density [https://en.wikipedia.org/wiki/Ochroma_pyramidale '''Balsa Wood''']. | ||

* Use any suitable adhesive to make connections but adhesive tape is not allowed | * Use any suitable '''[[Adhesive Types|adhesive]]''' to make connections but '''[[Adhesive Tapes|adhesive tape]]''' is not allowed. | ||

Revision as of 18:03, 12 January 2016

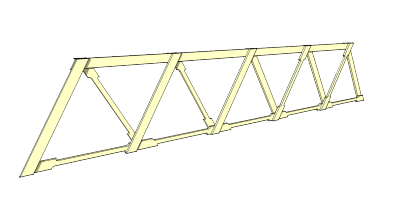

What to Make:

Design Make and Test a Warren Girder truss frame 450mm wide to span a 400mm wide gap and support a centrally applied load of 1kg

What to Use:

- Material available is restricted to 3mm thick medium density Balsa Wood.

- Use any suitable adhesive to make connections but adhesive tape is not allowed.

Things to find out and think about:

- Draw full-size a Warren Girder exactly 450mm wide

- Analyse the forces acting within a Warren Girder and determine which Members will be Struts and which will be Ties.

- Apply Bow's Notation and use Force Diagrams to determine the Forces in the Frame when the 1kg load is applied.

- Determine the Tensile Strength of medium density Balsa Wood either by testing or looking up in tables and from this establish how wide to cut Ties from 3mm thick sheet Balsa (e.g. U.T.S. should be around 15Nmm2 - use this figure if in doubt or to check magnitude of test results).

- Apply Euler's Buckling Equation to inform an estimate of how wide to cut the Struts from 3mm thick sheet Balsa (e.g. assume a figure for Young's Modulus (E) of 4000Nmm2 or determine by experiment by measuring the Deflection of a balsa sample beam for example).

Some ideas:

Ways of Making:

- Conduct some tests to establish which is the most effective adhesive and consider how each joint can be provided with an adequate gluing surface area.

- Take care when shaping and finishing the Structural Members to avoid any nicks or sharp indentations which might cause a Stress Concentration.

- Use the full-size drawing to position the Structural Members accurately and glue them in place.

Note: Cover the drawing with tracing paper to enable the truss frame to release after gluing.

Testing:

- Carefully weigh the completed truss frame (ideally to 1/10th of a gram).

- Mount the completed truss frame in the testing rig as shown

- Suspend a mass set hanger from the centre as shown

- Add masses carefully to avoid generating a Dynamic Load until the specified load of 1kg is reached.

- Divide 1kg by the truss frame self-weight to gain a measure of the frame's efficiency (i.e. high numbers win!)

Further Work:

- Continue to load the fram until it fails and record the maximum load before failure.

- Divide the maximum load before failure by self-weight to gain a revised measure of the frame's efficiency.

- Observe how the frame failed : which Member failed first? Was it a Strut or a Tie? Did just one Member fail or several all at once - and what would this indicate?