Biscuit Joint: Difference between revisions

From DT Online

m Added link |

Added Template |

||

| Line 1: | Line 1: | ||

[[File:BiscuitJointedTee.png|300px|right]] | [[File:BiscuitJointedTee.png|300px|right]] | ||

__TOC__ | |||

=====Description===== | |||

A [https://en.wikipedia.org/wiki/Butt_joint#Biscuit_reinforced_butt_joint '''Biscuit Joint'''] is a type of reinforced '''[[Butt Joint]]''' made by inserting dried and compressed wooden '''[[Jointing Biscuit|Biscuits]]''' into pre-cut slots or '''Grooves'''. The joining system was developed in the 1950's by a Swiss carpenter ''([https://en.wikipedia.org/wiki/Hermann_Steiner Hermann Steiner])'' as a means of joining together '''[[Manufactured Board|Chipboard]]'''. | A [https://en.wikipedia.org/wiki/Butt_joint#Biscuit_reinforced_butt_joint '''Biscuit Joint'''] is a type of reinforced '''[[Butt Joint]]''' made by inserting dried and compressed wooden '''[[Jointing Biscuit|Biscuits]]''' into pre-cut slots or '''Grooves'''. The joining system was developed in the 1950's by a Swiss carpenter ''([https://en.wikipedia.org/wiki/Hermann_Steiner Hermann Steiner])'' as a means of joining together '''[[Manufactured Board|Chipboard]]'''. | ||

=====Features and Applications===== | |||

The compressed '''[[Jointing Biscuit|Biscuits]]''' are quite loose in the '''Slots''' or '''Grooves''' when first assembled but swell to become a tight fit when the glue wets them. This makes the joints easy to assemble but requires them to remain longer in '''[[Sash Cramp|Cramps]]''' when glued. | The compressed '''[[Jointing Biscuit|Biscuits]]''' are quite loose in the '''Slots''' or '''Grooves''' when first assembled but swell to become a tight fit when the glue wets them. This makes the joints easy to assemble but requires them to remain longer in '''[[Sash Cramp|Cramps]]''' when glued. | ||

| Line 16: | Line 21: | ||

---- | ---- | ||

{{Biscuit Jointer Buyers Guide}} | |||

[[Category:Wood Joints]] | [[Category:Wood Joints]] | ||

Revision as of 11:55, 8 June 2016

Description

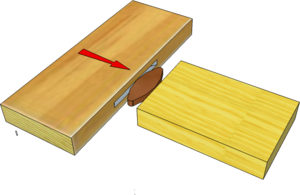

A Biscuit Joint is a type of reinforced Butt Joint made by inserting dried and compressed wooden Biscuits into pre-cut slots or Grooves. The joining system was developed in the 1950's by a Swiss carpenter (Hermann Steiner) as a means of joining together Chipboard.

Features and Applications

The compressed Biscuits are quite loose in the Slots or Grooves when first assembled but swell to become a tight fit when the glue wets them. This makes the joints easy to assemble but requires them to remain longer in Cramps when glued.

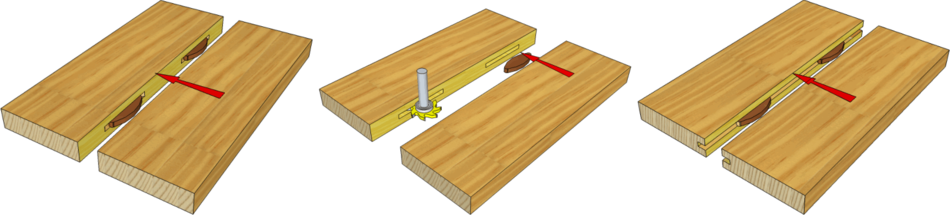

Biscuit Joints are often used to strengthen a Widening Joint but can be used in many joint configurations. The Biscuits can be fitted in to the crescent shaped slots machined specifically for the task by a Biscuit Jointer, into a similar shaped slot machined by a Router fitted with a Slot Cutter or simply set alongside each other in a continuous through Groove.

Safety Point! Students may only use a Router or Biscuit Jointer when they have been trained and assessed and the assessment shows that they are competent, and are under appropriate supervision of specifically trained staff.

- The crescent-shaped slots to receive the compressed wooden Biscuits are most easily cut using a purpose made Biscuit Jointer

- But the joining Biscuits can be used also in similar slots created by a Router fitted with a suitable Slot Cutter or into a continuous Groove along the edge of the timber.

|

|

|

|

|

|

|

| Mixed Jointing Biscuits |

Draper Biscuit Jointer |

Makita 240V Biscuit Jointer |

Makita Cordless Biscuit Jointer |

DeWalt Biscuit Jointer |

Tungsten Carbide Biscuit Jointer |

Bosch Router |