Rivets: Difference between revisions

From DT Online

mNo edit summary |

Created Article |

||

| Line 1: | Line 1: | ||

[[File:Rocks Bridge rivets.JPG|300px|right]] | [[File:Rocks Bridge rivets.JPG|300px|right]] | ||

[https://en.wikipedia.org/wiki/Rivet '''Rivets'''] ''(aka Rivits)'' can be solid or hollow and specialised designs | [https://en.wikipedia.org/wiki/Rivet '''Rivets'''] ''(aka Rivits)'' have various designs of head at one end and are used to fasten materials together by being passed through a punched or drilled hole and hammered over ''(usually)'' to form a head on the reverse side. They are available in several materials and sizes, can be solid or hollow and specialised designs also exist ''(e.g. ‘Pop’ Rivets). | ||

In general, '''Rivets''' are first passed through the punched or drilled holes then, with head supported on a hard surface, a hollow tool with a hole equal to the '''Rivet''' diameter is struck down over it to squeeze, or '''Set''', the pieces of material together. The tool, or '''Rivet Set''', is removed and using a hammer, the '''Rivet''' is first struck [[Squareness|square on]] to thicken it inside the holes, then the head is formed by hammering over. | |||

In traditional boilermaking, ship building and bridge girder construction for example, large iron rivets were passed through the plates to be joined and hammered over whilst red hot. This not only made the hammering over easier but, as the iron rivet cooled, the joint tightened due to its contraction. | |||

---- | |||

<span style="color: green">'''Note:''' | |||

Where several '''Rivets''' are to be used to form a joint, it is important to drill through both parts just once initally, and this hole rivetted before drilling through and rivetting any further holes. This is because it is most unlikely that drilling separately would position the holes accurately enough. | |||

</span> | |||

---- | |||

__TOC__ | |||

=====Solid Rivets===== | |||

{| | |||

|- | |||

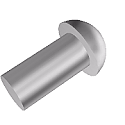

| [https://en.wikipedia.org/wiki/Rivet#Solid.2Fround_head_rivets '''Snap Head Rivet'''] | |||

| B | |||

| [[File:SnapHd.png|125px|right]] | |||

|- | |||

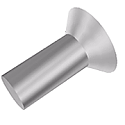

| [https://en.wikipedia.org/wiki/Rivet#Flush_rivet '''Countersunk Head Rivet'''] | |||

| B | |||

| [[File:CskHd.png|125px|right]] | |||

|- | |||

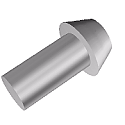

| '''Flat Head Rivet''' | |||

| B | |||

| [[File:FlatHd.png|125px|right]] | |||

|- | |||

| '''Pan Head Rivet''' | |||

| B | |||

| [[File:PanHd.png|125px|right]] | |||

|} | |||

====='Pop' Rivets===== | |||

{| | |||

|- | |||

| [https://en.wikipedia.org/wiki/Rivet#Blind_rivets '''Domed Head 'Pop' Rivet'''] | |||

| B | |||

| [[File:PopRivet.png|125px|right]] | |||

|- | |||

| [https://en.wikipedia.org/wiki/Rivet#Blind_rivets '''Large Flange 'Pop' Rivet''] | |||

| B | |||

| [[File:PopRivet1.png|125px|right]] | |||

|} | |||

=====Specialised Rivets===== | |||

{| | |||

|- | |||

| '''Hollow Rivet''' | |||

| B | |||

| [[File:###|125px|right]] | |||

|- | |||

| '''Birfurcated Rivet''' | |||

| B | |||

| [[File:###|125px|right]] | |||

|- | |||

| [https://en.wikipedia.org/wiki/Rivet_nut '''Rivet Nut'''] | |||

| B | |||

| [[File:###|125px|right]] | |||

|} | |||

[[Category:Fixings and Fastenings]] | |||

Revision as of 13:27, 20 August 2015

Rivets (aka Rivits) have various designs of head at one end and are used to fasten materials together by being passed through a punched or drilled hole and hammered over (usually) to form a head on the reverse side. They are available in several materials and sizes, can be solid or hollow and specialised designs also exist (e.g. ‘Pop’ Rivets).

In general, Rivets are first passed through the punched or drilled holes then, with head supported on a hard surface, a hollow tool with a hole equal to the Rivet diameter is struck down over it to squeeze, or Set, the pieces of material together. The tool, or Rivet Set, is removed and using a hammer, the Rivet is first struck square on to thicken it inside the holes, then the head is formed by hammering over.

In traditional boilermaking, ship building and bridge girder construction for example, large iron rivets were passed through the plates to be joined and hammered over whilst red hot. This not only made the hammering over easier but, as the iron rivet cooled, the joint tightened due to its contraction.

Note: Where several Rivets are to be used to form a joint, it is important to drill through both parts just once initally, and this hole rivetted before drilling through and rivetting any further holes. This is because it is most unlikely that drilling separately would position the holes accurately enough.

Solid Rivets

| Snap Head Rivet | B |  |

| Countersunk Head Rivet | B |  |

| Flat Head Rivet | B |  |

| Pan Head Rivet | B |  |

'Pop' Rivets

| Domed Head 'Pop' Rivet | B |  |

| 'Large Flange 'Pop' Rivet | B |  |

Specialised Rivets

| Hollow Rivet | B | [[File:###|125px|right]] |

| Birfurcated Rivet | B | [[File:###|125px|right]] |

| Rivet Nut | B | [[File:###|125px|right]] |